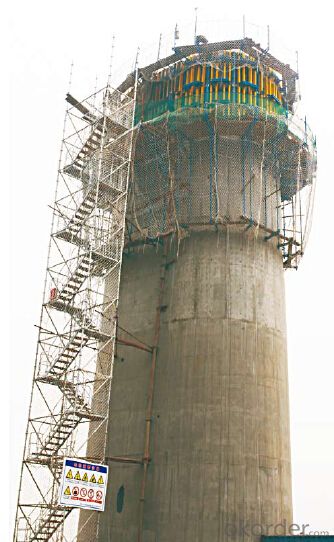

Stair Tower for Formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for both horizontal and vertical concrete placements?

- Yes, steel formwork can be used for both horizontal and vertical concrete placements. Steel formwork provides a strong and durable structure that can withstand the pressure exerted by concrete during pouring and curing processes. It is versatile and can be easily assembled and disassembled, making it suitable for various construction applications.

- Q: How is steel formwork transported to the construction site?

- Depending on the distance, quantity, and accessibility of the construction site, steel formwork is transported using different methods. Truck transportation is a common choice for shorter distances and smaller quantities. This involves loading the steel formwork components onto a flatbed or trailer and driving them to the site. For larger quantities or longer distances, rail or sea transportation may be used. Rail transport is efficient for moving large quantities over long distances, especially when the site is far from the manufacturing facility. On the other hand, sea transport is ideal for international projects that require shipping the formwork overseas. The formwork is loaded into shipping containers and transported by cargo ships. Upon arrival at the construction site, cranes or forklifts are used to unload the steel formwork. The components are then stored in a designated area until they are ready for installation. It is crucial to carefully plan and execute the transportation process to prevent any damage to the formwork. Any issues with structural integrity can adversely affect the quality and safety of the final construction project.

- Q: Can steel formwork be used for projects with limited formwork budget?

- Yes, steel formwork can be used for projects with limited formwork budget. Steel formwork is durable, reusable, and has a longer lifespan compared to other types of formwork. It requires less maintenance and can be used for multiple projects, making it a cost-effective option in the long run. Additionally, steel formwork provides better quality finishes and allows for faster construction, reducing labor costs and overall project duration.

- Q: How does steel formwork handle concrete surface finishing?

- Steel formwork is known for its durability and strength, making it highly effective in handling concrete surface finishing. It provides a smooth and even surface, allowing for precise and accurate finishing techniques such as troweling or polishing. Additionally, steel formwork minimizes the risk of surface imperfections and ensures consistent results throughout the entire concrete structure. Its robustness also enables multiple reuses, reducing construction costs and enhancing overall efficiency.

- Q: What are the different types of formwork accessories used with steel formwork?

- There are several types of formwork accessories used with steel formwork, including form ties, formwork clamps, spreader bars, formwork brackets, formwork support systems, and scaffold brackets. These accessories play essential roles in ensuring the stability, alignment, and overall efficiency of the steel formwork during the construction process.

- Q: Can steel formwork be used in curved or irregular structures?

- Curved or irregular structures can indeed make use of steel formwork. This type of formwork grants great flexibility and can be effortlessly modified to generate different shapes and curves. It presents the benefit of withstanding substantial pressure, enabling the efficient and accurate construction of curved or irregular structures. Steel formwork is especially appropriate for intricate architectural designs and structures necessitating distinctive shapes, like curved walls, columns, and beams. Furthermore, the durability and strength of steel render it a dependable option for such applications, guaranteeing the stability and longevity of the structure.

- Q: How does steel formwork affect the overall construction site organization?

- Steel formwork can have a significant impact on the overall organization of a construction site. Firstly, steel formwork is known for its durability and reusability, which means it can be used multiple times for different projects. This allows for better planning and scheduling of construction activities, as the availability of formwork is more predictable and reliable. Additionally, steel formwork is known for its precision and accuracy, which leads to better quality construction. This can result in fewer reworks and delays, as the formwork ensures that concrete is poured in the right place and to the correct dimensions. Consequently, the overall construction process becomes more efficient, allowing for better organization and coordination of various trades and activities on the site. Steel formwork also offers flexibility in design and construction. It can be easily adjusted and modified to accommodate changes in the project, such as alterations in the shape or size of concrete elements. This adaptability reduces the need for additional materials and resources, which can streamline the organization of the construction site and minimize waste. Furthermore, steel formwork is known for its strength and stability. This allows for taller and larger concrete structures to be constructed, which can have implications for the overall layout and organization of the site. For example, it may require additional crane or lifting equipment to handle the heavier and larger formwork components. This necessitates careful planning and coordination to ensure that the site is properly organized to accommodate these requirements. In summary, steel formwork positively impacts the overall organization of a construction site by providing durability, precision, flexibility, and strength. These attributes contribute to better planning, scheduling, and coordination of construction activities, resulting in improved efficiency, quality, and adaptability.

- Q: What are the considerations when designing steel formwork for underground parking structures?

- When designing steel formwork for underground parking structures, there are several important considerations that need to be taken into account. These considerations include: 1. Structural Stability: Underground parking structures experience significant loads from the surrounding soil, as well as the weight of the vehicles they will accommodate. It is crucial to design the steel formwork in a way that ensures structural stability and can withstand these loads. 2. Water Resistance: Underground parking structures are susceptible to water infiltration, especially in areas with high groundwater levels. The steel formwork should be designed to be watertight, with proper sealing and waterproofing measures in place, to prevent water damage and maintain the integrity of the structure. 3. Fire Resistance: Fire safety is of utmost importance in underground parking structures. The steel formwork should be designed to meet the required fire resistance standards and provide adequate protection against fire hazards. 4. Durability: Underground parking structures are subject to constant traffic and wear and tear. The steel formwork should be designed to be durable and able to withstand the load and stress imposed by vehicles, as well as any potential impact from collisions or accidents. 5. Accessibility and Efficiency: The design of the steel formwork should take into consideration the accessibility of the parking structure, including the layout of ramps, entrances, and exits. It should also aim to maximize space utilization and efficiency, providing adequate parking slots without compromising safety or ease of use. 6. Maintenance and Repairs: The design should also consider the ease of maintenance and repairs. Accessible areas for inspection, maintenance, and repairs should be incorporated into the formwork design to ensure that any necessary maintenance or repairs can be carried out efficiently. 7. Cost-effectiveness: Finally, the design should strike a balance between meeting all the necessary requirements and being cost-effective. It is essential to consider the overall cost of materials, construction, and maintenance when designing the steel formwork for underground parking structures. By carefully considering these considerations, engineers and designers can create effective and efficient steel formwork for underground parking structures that meet all the necessary requirements for safety, durability, and functionality.

- Q: Is steel formwork suitable for all types of concrete structures?

- When considering formwork options for concrete structures, steel formwork is often deemed suitable. However, its appropriateness can be influenced by various factors including design requirements, budget constraints, and project timeline. Steel formwork boasts several advantages compared to alternative systems. Its exceptional strength and durability enable it to withstand the pressure exerted by fresh concrete without warping or deforming. As a result, it is particularly well-suited for structures that necessitate substantial concrete pours or possess intricate geometries. Furthermore, steel formwork guarantees excellent dimensional accuracy, ensuring that the final concrete structure meets the prescribed specifications. Additionally, it allows for easy customization, enabling tailoring to the specific needs of the project. Nevertheless, there are situations where steel formwork may not be the most appropriate choice. For instance, if budget limitations exist, steel formwork may prove costlier than alternatives like timber or plastic formwork. Moreover, if the project operates on a tight schedule, steel formwork may necessitate more time for fabrication and assembly compared to other systems. Moreover, steel formwork may not be the optimal selection for structures with stringent aesthetic requirements. The steel panels may leave imprints on the concrete surface, which may not align with certain architectural designs. In conclusion, although steel formwork is generally suitable for a broad array of concrete structures, its suitability may fluctuate based on project-specific factors such as design requirements, budget, and timeline. It is vital to meticulously evaluate these factors before determining the most fitting formwork system for a particular project.

- Q: Can steel formwork be customized to specific project requirements?

- Yes, steel formwork can be customized to specific project requirements. Steel is a versatile material that can be easily molded and fabricated to meet the specific shape, size, and design requirements of a project. This allows for the creation of complex and unique formwork structures that can be used to cast concrete in various shapes and sizes. Additionally, steel formwork can be adjusted and modified during the construction process to accommodate any changes or alterations that may be required. This flexibility and adaptability make steel formwork an ideal choice for projects with specific and customized requirements.

Send your message to us

Stair Tower for Formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords