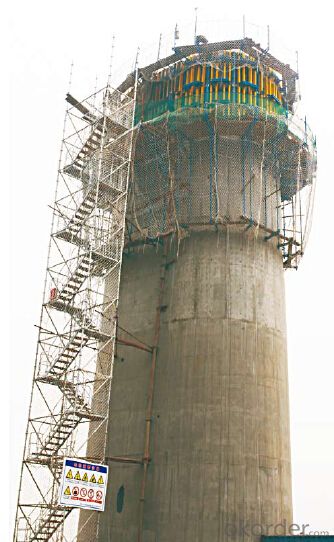

Stair Tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for elevated walkways?

- Yes, steel formwork can be used for elevated walkways. Steel formwork offers high strength, durability, and stability, making it suitable for supporting the weight and load of an elevated walkway. Additionally, steel formwork provides a smooth and level surface, ensuring a safe and stable walking platform for pedestrians.

- Q: Can steel formwork be used for both small-scale and large-scale construction projects?

- Yes, steel formwork can be used for both small-scale and large-scale construction projects. Its strength and durability make it suitable for various types of projects, regardless of their size. Additionally, steel formwork offers flexibility and can be easily customized to meet the specific requirements of different construction projects, making it a versatile choice for both small and large-scale construction.

- Q: How does steel formwork handle formwork stripping and cleaning?

- Steel formwork is known for its durability and strength, making it highly suitable for handling formwork stripping and cleaning processes. When it comes to formwork stripping, steel formwork can easily be disassembled and removed from the concrete structure without causing damage. This is due to the inherent rigidity and stability of steel, which allows for efficient and safe stripping. Moreover, steel formwork is resistant to moisture, chemicals, and other environmental factors, making it easier to clean and maintain. After the formwork is stripped, any concrete residue or debris can be easily removed from the steel surface using appropriate cleaning techniques. This may involve the use of high-pressure water jets, scrubbing, or other cleaning agents, depending on the specific requirements. Steel formwork also offers the advantage of reusability, as it can withstand multiple uses without significant deterioration. Once the formwork is cleaned, it can be inspected for any damages or wear and tear. Any necessary repairs or replacements can be made to ensure the formwork's integrity for future use. In summary, steel formwork handles formwork stripping and cleaning efficiently due to its durability, strength, and resistance to environmental factors. Its easy disassembly, cleaning capabilities, and reusability make it a preferred choice for construction projects where formwork needs to be stripped and maintained regularly.

- Q: How does steel formwork affect the overall structural integrity of a building?

- Steel formwork can significantly enhance the overall structural integrity of a building. Due to its high strength and durability, steel formwork provides a rigid framework for concrete placement, ensuring that the structure maintains its shape and stability during the construction process. This formwork system also allows for accurate and precise molding of concrete, resulting in uniformity and consistency in the building's structure. Additionally, steel formwork is highly resistant to deformation, which reduces the risk of any structural damage or failure. Overall, steel formwork plays a crucial role in maintaining the strength and stability of a building, contributing to its long-term structural integrity.

- Q: How does steel formwork handle formwork repositioning?

- Steel formwork is highly durable and flexible, making it ideal for handling formwork repositioning. Its sturdy construction allows for easy dismantling, transportation, and reassembly in new locations. Steel formwork systems typically consist of modular panels that can be easily adjusted and reconfigured to accommodate different shapes and sizes of concrete structures. This versatility and adaptability make steel formwork a preferred choice in construction projects where formwork repositioning is required.

- Q: How does steel formwork accommodate for different concrete curing temperatures?

- Accommodating various concrete curing temperatures is easily achieved with steel formwork, thanks to its versatility and reliability. The standout characteristic of steel formwork is its exceptional thermal conductivity, which effectively dissipates heat from curing concrete. This unique property enables the steel formwork to effectively regulate the concrete's temperature during the curing process. When precise control over the concrete curing temperature is necessary, steel formwork can be equipped with additional features to meet these requirements. For example, insulation materials can be applied to the steel formwork to minimize heat loss or gain, ensuring a consistent and steady curing temperature. This adaptation proves especially beneficial in extreme weather conditions when the ambient temperature can have a significant impact on the curing process. Furthermore, steel formwork can be combined with heating or cooling systems to further regulate the concrete curing temperature. In colder weather conditions, heating elements can be integrated into the steel formwork to maintain an optimal temperature for proper curing. Similarly, in hotter weather conditions, cooling systems can be employed to prevent excessive heat from affecting the curing process. In addition to its temperature control capabilities, steel formwork boasts exceptional strength and durability, making it an ideal choice for accommodating various concrete curing temperatures. The robust nature of steel formwork allows it to withstand the pressure and stresses exerted by the curing concrete, regardless of the temperature. This ensures that the formwork remains intact and stable throughout the curing process, preventing any deformations or failures that could compromise the quality of the concrete structure. Overall, steel formwork offers a comprehensive solution for accommodating different concrete curing temperatures. Its high thermal conductivity, compatibility with insulation materials, and integration with heating or cooling systems make it a versatile option. Additionally, its strength and durability guarantee its ability to withstand the challenges posed by varying curing temperatures, ensuring successful and optimal concrete curing.

- Q: How does steel formwork handle different concrete admixtures?

- Steel formwork is a highly versatile and durable system that is capable of handling various concrete admixtures. Admixtures are added to concrete to enhance its properties, such as strength, workability, durability, and setting time. One of the key advantages of steel formwork is its ability to withstand the chemical reactions caused by different concrete admixtures. Steel is highly resistant to corrosion and can withstand the alkaline environment of concrete, as well as the potential chemical reactions caused by admixtures. Steel formwork can effectively handle admixtures like accelerators, retarders, plasticizers, and air-entraining agents, among others. Accelerators are used to speed up the setting and hardening process of concrete, while retarders are used to slow down the setting time. Steel formwork can accommodate the varying setting times caused by these admixtures, allowing for efficient construction processes. Plasticizers, also known as water-reducers, are commonly used to improve the workability and flow of concrete, making it easier to pour and shape. Steel formwork can easily handle the higher fluidity of concrete with plasticizers, ensuring that the concrete maintains its shape and does not leak or slump excessively. Another important admixture is air-entraining agents, which introduce microscopic air bubbles into the concrete. These air bubbles enhance the durability and freeze-thaw resistance of concrete. Steel formwork can handle the entrapped air and maintain the required consistency and structural integrity of the concrete. Furthermore, steel formwork can also handle other specialized admixtures such as corrosion inhibitors, shrinkage reducers, and waterproofing agents. These admixtures are used to address specific challenges associated with concrete construction, and steel formwork provides a reliable and stable platform for their successful implementation. In summary, steel formwork is a robust and adaptable system that can effectively handle various concrete admixtures. Its resistance to corrosion and stability make it an ideal choice for accommodating the chemical reactions and properties of different admixtures, resulting in high-quality and durable concrete structures.

- Q: Can steel formwork be used in seismic-prone areas?

- Yes, steel formwork can be used in seismic-prone areas. Steel formwork is known for its high strength and durability, making it suitable for use in areas with high seismic activity. It provides excellent resistance against the lateral forces generated during an earthquake, ensuring the structural integrity of the formwork system. Additionally, steel formwork offers flexibility in design and can be easily adjusted or modified to accommodate the specific requirements of seismic-prone areas. It is important, however, to ensure proper engineering and design considerations are applied when using steel formwork in these areas to ensure it meets the necessary safety standards and regulations.

- Q: Can steel formwork be used for industrial projects?

- Yes, steel formwork can be used for industrial projects. Steel formwork offers high strength, durability, and stability, making it suitable for demanding industrial applications. It can withstand heavy loads, provide accurate and precise formwork, and be reused multiple times, making it cost-effective for industrial projects.

- Q: Can steel formwork be used for structures with high thermal insulation requirements?

- No, steel formwork is not typically used for structures with high thermal insulation requirements.

Send your message to us

Stair Tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords