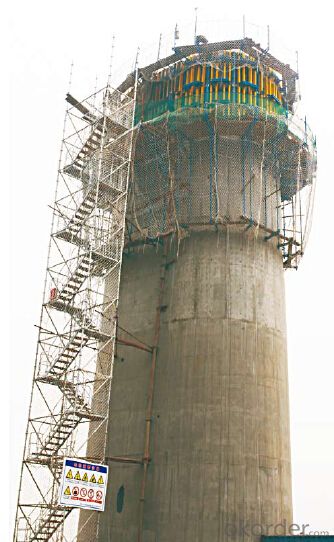

Stair Tower for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: How does steel formwork handle concrete vibration during pouring?

- Steel formwork, widely used in concrete pouring processes, is a versatile and durable construction material. It possesses several advantages when it comes to managing concrete vibration during pouring. To begin with, the high strength and rigidity of steel formwork enable it to withstand the intense vibrations caused by the pouring of concrete. Its robustness ensures stability and prevents potential deformation or collapse that weaker materials might experience. Moreover, steel formwork is designed with interlocking systems and tight joints, minimizing the possibility of concrete leakage. This containment of the concrete within the formwork streamlines the pouring process, reducing the need for excessive cleanup or rework. Furthermore, steel formwork efficiently transmits vibrations throughout its structure. This transmission aids in eliminating air bubbles and voids, resulting in a more uniform and compact final product. Effective vibration transmission enhances the overall strength and durability of the structure. Lastly, steel formwork is highly reusable and easily disassembled, making it ideal for multiple projects. This cost-effective and sustainable quality reduces the requirement for constant replacement of formwork materials. The ability to reuse steel formwork also ensures its consistent effectiveness in handling concrete vibration over time. In conclusion, steel formwork is a dependable and efficient material for managing concrete vibration during pouring. Its strength, stability, and vibration transmission capabilities make it a preferred choice in construction projects involving concrete pouring and compaction.

- Q: How does steel formwork affect the overall construction waste management?

- Steel formwork can significantly impact overall construction waste management by reducing waste generation and improving recycling opportunities. Unlike traditional timber formwork, steel formwork is more durable and can be reused multiple times, reducing the amount of waste generated during the construction process. Additionally, steel formwork can be easily dismantled and transported, allowing for efficient recycling and proper disposal of construction waste. This not only minimizes the environmental impact but also reduces the cost associated with waste disposal, making steel formwork a more sustainable and cost-effective solution for construction waste management.

- Q: Can steel formwork be used in areas with high moisture content?

- Yes, steel formwork can be used in areas with high moisture content. Steel is highly resistant to moisture, making it suitable for use in humid or wet environments. It is less likely to warp, rot, or deteriorate compared to other materials like wood. However, proper surface protection such as anti-corrosion coatings or galvanization may be required to ensure the longevity and performance of the steel formwork in high moisture conditions.

- Q: Is steel formwork resistant to corrosion?

- Steel formwork is typically resistant to corrosion. Steel, especially stainless steel, is renowned for its exceptional resistance to corrosion, rendering it an appropriate option for construction purposes. Nevertheless, it is crucial to acknowledge that the level of corrosion resistance may vary based on factors like the grade of steel employed, the environment in which the formwork is utilized, and the existence of any supplementary protective coatings. Consistent upkeep and appropriate maintenance practices can also contribute to the elongation of the lifespan and corrosion resistance of steel formwork.

- Q: How do steel formwork systems differ from one another?

- There are several ways in which steel formwork systems can vary from one another. Firstly, their design and construction can be different. Certain systems are modular and consist of pre-assembled panels that can be easily connected and adjusted to create various shapes and sizes. On the other hand, there are custom-made systems that are specifically tailored for particular projects, offering more flexibility in formwork design. Secondly, the strength and durability of steel formwork systems can differ. Some systems are engineered to withstand heavy loads and extreme conditions, making them suitable for large-scale construction projects. Conversely, there are lighter and more portable systems that are better suited for smaller projects or areas with limited access. Another aspect that sets steel formwork systems apart is their user-friendliness. Some systems are designed to be easy to use, with built-in handles, adjustable brackets, and user-friendly locking mechanisms. These features allow for quick and efficient installation and dismantling, saving time and effort on the construction site. Furthermore, steel formwork systems can offer different finishing options. Some provide smooth and precise finishes, which are ideal for projects that require a high-quality surface. Others have textured or patterned finishes, adding a decorative element to the concrete structure. Lastly, steel formwork systems can vary in terms of their cost and availability. Some systems are more affordable and readily available, making them a popular choice for smaller projects or contractors on a tight budget. On the other hand, there are systems that are more expensive or require longer lead times for fabrication, but offer advanced features or customization options. In conclusion, the distinctions between steel formwork systems lie in their design, strength, ease of use, finishing options, and cost. Contractors and construction professionals should carefully assess these factors to choose the most suitable steel formwork system for their specific project requirements.

- Q: What are the different types of formwork ties used in steel formwork?

- There are several different types of formwork ties that are commonly used in steel formwork systems. These ties are essential for holding the formwork panels together and ensuring the stability and strength of the formwork structure. 1. Wedge Tie: This is the most common type of formwork tie used in steel formwork. It consists of a wedge-shaped metal piece that is inserted into a hole in the formwork panel. The wedge is then tightened, creating a strong connection and holding the panels in place. 2. Pin and Wedge Tie: This type of tie consists of a pin and a wedge. The pin is inserted into a hole in the formwork panel and then the wedge is driven into the pin, creating a tight connection. 3. Wing Nut and Tie Rod: This tie system uses a wing nut and a tie rod to hold the formwork panels together. The tie rod is threaded through the panels and secured with a wing nut on each side. This type of tie allows for easy removal and reassembly of the formwork. 4. Coil Tie: A coil tie is a type of tie that is used when the formwork panels need to be secured to the steel reinforcement bars. The tie is threaded through the formwork panel and then wrapped around the reinforcement bar, creating a secure connection. 5. Flat Tie: Flat ties are used to connect the formwork panels in situations where the panels need to be secured tightly against each other. These ties are flat metal strips that are inserted into holes in the formwork panels and then tightened. These are just a few examples of the different types of formwork ties used in steel formwork systems. The choice of tie will depend on factors such as the specific formwork design, the load requirements, and the ease of installation and removal. It is important to select the appropriate tie system to ensure the stability and safety of the formwork structure.

- Q: How does steel formwork affect the overall noise transmission in the building?

- Steel formwork can have a significant impact on the overall noise transmission in a building. Compared to other types of formwork materials, such as wood or plastic, steel is much denser and less porous. This density and lack of porosity make steel formwork highly effective in reducing the transmission of sound waves through the structure. When steel formwork is used, it creates a more rigid and solid structure, minimizing the vibrations caused by external noise sources. This rigidity helps to prevent the amplification and propagation of sound waves throughout the building. As a result, the overall noise transmission is significantly reduced, creating a quieter and more comfortable environment for the occupants. Furthermore, steel formwork can also act as a barrier to airborne sound, preventing sound waves from passing through the walls or floors. This is particularly important in buildings where privacy is crucial, such as hospitals, offices, or residential buildings. In addition to its soundproofing capabilities, steel formwork also offers other advantages. It is durable, reusable, and has a longer lifespan compared to other formwork materials. This not only reduces construction costs but also contributes to the sustainability of the building. Overall, the use of steel formwork in construction has a positive impact on the overall noise transmission in the building. Its density and rigidity effectively reduce the transmission of sound waves, creating a quieter and more comfortable environment for the occupants.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers durability and strength, making it suitable for creating precise and complex shapes required for precast concrete columns. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for precast concrete column production.

- Q: What are the typical corrosion protection measures for steel formwork systems?

- To help prolong the lifespan and maintain the structural integrity of steel formwork systems, there are various typical measures for corrosion protection. One method that is commonly used involves applying protective coatings. These coatings, such as epoxy coatings, act as a barrier against moisture and corrosive elements. They are usually applied to the entire surface of the steel formwork system, including joints and connection points, to prevent direct contact between the steel and the surrounding environment. Another measure that can be taken is galvanizing. This process entails coating the steel formwork system with a layer of zinc, creating a protective barrier against corrosion. Galvanizing is particularly effective in environments with high moisture levels or exposure to saltwater, such as coastal areas. Regular maintenance is crucial for corrosion protection as well. It is important to regularly inspect the formwork system for any signs of damage or deterioration, such as rust or pitting. Any areas of concern should be promptly addressed through repair or replacement. Additionally, regular cleaning and removal of debris or contaminants can help prevent corrosion. Proper storage and handling of the steel formwork system is another significant measure. It is essential to store the formwork in a dry and well-ventilated area to minimize exposure to moisture. Moreover, it should be handled correctly to avoid unnecessary damage or scratches that could compromise the protective coatings. Lastly, sacrificial anodes can be utilized as a corrosion protection measure. These anodes, typically made from a metal more reactive than the steel formwork system, like zinc or magnesium, corrode in place of the steel, effectively sacrificing themselves to protect the system. In summary, employing a combination of protective coatings, galvanizing, regular maintenance, proper storage, and sacrificial anodes can ensure effective corrosion protection for steel formwork systems, guaranteeing their longevity and durability.

- Q: Are there any specific building codes or regulations related to steel formwork?

- Yes, there are specific building codes and regulations related to steel formwork. These codes and regulations are put in place to ensure the safety, stability, and integrity of structures constructed using steel formwork. One of the most widely recognized codes is the International Building Code (IBC), which provides minimum requirements for the design, construction, alteration, and maintenance of buildings and structures. The IBC includes provisions for formwork systems, including steel formwork, to ensure they meet certain standards of strength, durability, and stability. In addition to the IBC, several other organizations and agencies provide guidelines and standards for steel formwork. For example, the American Concrete Institute (ACI) has a document called ACI 347-04, Guide to Formwork for Concrete, which provides recommendations for the use of various types of formwork, including steel formwork. These codes and standards cover various aspects of steel formwork, including design, materials, construction, and inspection. They address issues such as the maximum allowable loads, proper bracing and shoring, formwork connections, and the quality of materials used. They also provide guidance on safety measures, such as fall protection, to ensure the well-being of workers during formwork installation and removal. It is important for builders, designers, and contractors to be familiar with these codes and regulations to ensure compliance and to guarantee the structural integrity and safety of buildings constructed using steel formwork. Local building departments and authorities having jurisdiction can provide specific information and requirements related to steel formwork in their respective regions.

Send your message to us

Stair Tower for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords