Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

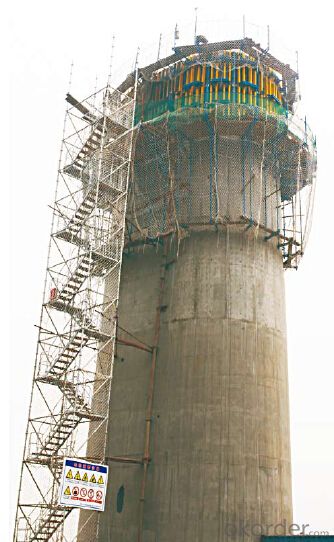

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Are there any regulations or standards that govern the use of steel formwork?

- Yes, there are regulations and standards that govern the use of steel formwork in construction. These regulations ensure the safety, quality, and performance of steel formwork systems. Some widely recognized standards include the American Concrete Institute (ACI) 347-04 and the Occupational Safety and Health Administration (OSHA) regulations. These standards provide guidance on design, installation, inspection, and maintenance of steel formwork to ensure its proper and safe use in construction projects.

- Q: Can steel formwork be used for both new construction and renovation projects?

- Yes, steel formwork can be used for both new construction and renovation projects. Steel formwork is highly versatile and can be easily adapted to fit various project requirements. It provides excellent strength and durability, making it suitable for both small and large-scale projects. Steel formwork can be used for constructing new structures as well as for renovating existing ones. It offers the advantage of being reusable, reducing costs and waste in the long run. Additionally, steel formwork allows for precise and accurate construction, ensuring high-quality results in both new construction and renovation projects.

- Q: All I know is that prices are different

- Ha-ha!From the material on a wooden template, a steel template;

- Q: How does steel formwork contribute to the overall safety of workers?

- Steel formwork contributes to the overall safety of workers in several ways. Firstly, steel formwork is known for its strength and durability, providing a stable and secure structure for workers to perform their tasks. This stability minimizes the risk of accidents and collapses, ensuring the safety of workers. Additionally, steel formwork is designed to be fire-resistant, offering protection in case of fire emergencies. This feature significantly reduces the risk of injuries and provides workers with valuable time to evacuate the area safely. Moreover, steel formwork is engineered to be resistant to various weather conditions, such as strong winds and heavy rains. This resistance prevents formwork from becoming unstable or collapsing during adverse weather, minimizing the risk of accidents and injuries for workers on-site. Furthermore, steel formwork is typically designed with safety features such as non-slip surfaces and handrails, enhancing worker safety by providing better grip and stability when moving around the structure. These features help prevent slips, trips, and falls, which are common causes of accidents on construction sites. Another important aspect is that steel formwork is reusable and can be easily assembled and disassembled. This reduces the need for workers to carry heavy materials or tools, decreasing the risk of strain injuries and fatigue-related accidents. Lastly, steel formwork is designed to ensure proper support and alignment, minimizing the risk of structural failures or collapses during concrete pouring. This precise alignment ensures the stability of the structure and reduces the likelihood of accidents that could endanger workers' safety. In conclusion, steel formwork plays a crucial role in enhancing the overall safety of workers. Its strength, durability, fire resistance, weather resistance, non-slip surfaces, and proper support contribute significantly to creating a secure working environment, reducing the risk of accidents, injuries, and structural failures.

- Q: How does steel formwork contribute to the overall cost-effectiveness of the construction process?

- Steel formwork contributes to the overall cost-effectiveness of the construction process in several ways. Firstly, steel formwork is reusable, allowing it to be used on multiple construction projects. This eliminates the need for frequent purchases or rentals of formwork, reducing costs in the long run. Secondly, steel formwork is durable and can withstand high pressures and loads, resulting in less damage or need for repairs during the construction process. This reduces downtime and saves on additional expenses. Lastly, steel formwork is highly efficient and can be assembled and disassembled quickly, saving labor costs and speeding up the construction timeline. Overall, the cost-effectiveness of steel formwork lies in its reusability, durability, and efficiency, making it a cost-saving choice for construction projects.

- Q: Can steel formwork be used for both vertical and horizontal structures?

- Indeed, steel formwork proves to be a viable option for both vertical and horizontal structures. This construction material showcases its versatility and durability, allowing it to be molded and shaped according to the specific requirements of different structural elements. Whether it be walls, columns, beams, slabs, or any other structural component, steel formwork can be utilized in both vertical and horizontal orientations. The robustness and firmness of steel make it capable of withstanding the considerable pressure exerted by concrete during the casting process, ensuring that the formwork maintains its shape and stability. Furthermore, steel formwork offers the advantage of reusability, as it can be easily dismantled and reassembled. This quality makes it a cost-effective and efficient choice for construction projects involving both vertical and horizontal structures.

- Q: Are there any specific safety guidelines for steel formwork installation?

- Steel formwork installation requires adherence to specific safety guidelines. The following key safety measures should be observed: 1. Training and Competency: All personnel involved in steel formwork installation must undergo proper training and possess the necessary skills. This includes knowledge of equipment, understanding of installation procedures, and awareness of potential hazards. 2. Personal Protective Equipment (PPE): Workers must wear appropriate PPE, including hard hats, safety glasses, gloves, and steel-toed boots. This is to protect against potential head, eye, hand, and foot injuries. 3. Inspection and Maintenance: Regular inspections should be conducted on the steel formwork and associated equipment to identify any defects or hazards. Immediate repairs or replacements should be carried out for damaged or faulty parts to ensure safety during installation. 4. Hazard Identification and Control: Before commencing installation, a comprehensive assessment of the work area must be performed to identify potential hazards, such as overhead power lines, uneven ground, or confined spaces. Adequate measures, like erecting barriers, using warning signs, or implementing fall protection systems, should be taken to control these hazards. 5. Manual Handling: Proper lifting techniques should be employed to prevent back injuries or strains. For heavy or awkward loads, the use of mechanical aids such as cranes or hoists should be considered. 6. Fall Protection: Due to the inherent risk of falls during steel formwork installation, especially when working at heights, the use of adequate fall protection systems, such as guardrails, safety nets, or personal fall arrest systems, is essential to prevent accidents and safeguard workers. 7. Communication and Coordination: Clear communication and coordination among the installation team are crucial for a safe installation process. Regular safety briefings, ensuring clear understanding of roles and responsibilities, and maintaining an open line of communication for reporting safety concerns are essential. It is important to note that these guidelines may vary depending on the specific project, local regulations, and industry standards. Therefore, it is advisable to consult with relevant authorities, such as the project engineer or site safety officer, to ensure compliance with all necessary safety requirements.

- Q: What are the common accessories used with steel formwork?

- Common accessories used with steel formwork include form ties, formwork clamps, scaffolding, adjustable steel props, and formwork braces.

- Q: Can steel formwork be used for both slab and column construction?

- Yes, steel formwork can be used for both slab and column construction. Steel formwork offers several advantages over other types of formwork, such as wood or plastic. It is highly durable and can withstand the pressure exerted by fresh concrete, making it suitable for use in both slab and column construction. For slab construction, steel formwork provides a strong and rigid support system, ensuring that the concrete is poured and cured in the desired shape and dimensions. The steel panels can be easily assembled and disassembled, allowing for efficient and repeated use on multiple projects. This saves both time and money in the long run. Similarly, steel formwork can also be used for column construction. The adjustable panels can be easily customized to various column sizes and shapes, providing flexibility in design. Steel formwork also offers a smooth surface finish, resulting in high-quality columns. Moreover, steel formwork is resistant to warping, swelling, and shrinking, which can occur with other types of formwork materials. This ensures that the concrete structure is built accurately and maintains its structural integrity over time. Overall, steel formwork is a versatile and reliable option for both slab and column construction. Its strength, durability, and ease of use make it a popular choice among construction professionals.

- Q: How does steel formwork affect the schedule of a construction project?

- Steel formwork can have a positive impact on the schedule of a construction project. Compared to traditional formwork methods, steel formwork is quicker to set up and dismantle, reducing the time required for formwork installation and removal. This efficiency allows for faster construction progress, enabling the project to stay on schedule or even be completed ahead of time. Additionally, steel formwork is highly durable and can be reused multiple times, further saving time by eliminating the need for constant formwork replacement.

Send your message to us

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords