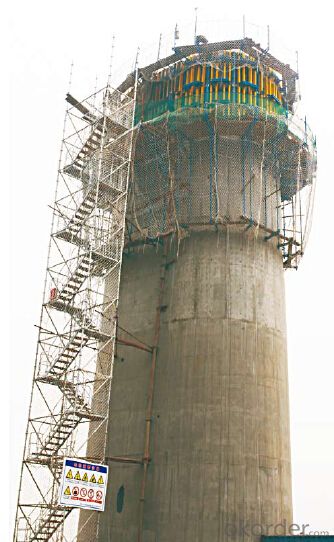

Stair tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: What are the safety precautions when working with steel formwork?

- When working with steel formwork, it is important to follow several safety precautions to ensure the well-being of workers. These precautions include wearing personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toed boots. It is also crucial to inspect the formwork for any damages or defects before using it, as well as to secure it properly to prevent collapse or movement during construction. Adequate training and supervision should be provided to workers, and they should be cautious of potential hazards such as sharp edges, heavy lifting, and working at heights. Regular communication and adherence to safety protocols are key to minimizing accidents and ensuring a safe working environment.

- Q: How does steel formwork affect the overall structural integrity of a building?

- The overall structural integrity of a building is heavily reliant on steel formwork. During the construction process, steel formwork is used as a temporary mold or framework to shape and support concrete until it hardens and gains enough strength to bear its own weight and other applied loads. One of the main benefits of steel formwork is its superior strength and durability in comparison to other types of formwork like wood or plastic. Steel possesses high tensile strength and resistance to deformation, enabling it to withstand the pressure exerted by wet concrete without significant distortion. This strength ensures that the formwork maintains its shape and stability throughout the pouring and curing of concrete, preventing any potential collapse or failure that could compromise the building's structural integrity. Moreover, the use of steel formwork delivers precise and accurate results in terms of dimension and shape, which is crucial for achieving the desired structural integrity. Steel formwork can be fabricated to exact specifications, allowing for tight tolerances and precise positioning of reinforcement, resulting in a more uniform and robust structure. This precision guarantees that the building can endure various external loads, such as wind, seismic forces, and live loads, without excessive deflection or deformation. Additionally, steel formwork offers excellent reusability, making it a cost-effective and sustainable choice for construction projects. Unlike other formwork types that may require frequent replacement, steel formwork can be used multiple times, reducing material waste and overall project costs. This reusability also contributes to the building's structural integrity, as the formwork is less prone to deterioration or degradation over time, ensuring consistent quality and performance. To summarize, steel formwork significantly enhances the overall structural integrity of a building by providing superior strength, precision, and durability. Its ability to withstand the pressure of wet concrete, maintain accurate dimensions, and resist external loads ensures the building's structural stability and safety. Furthermore, the reusability of steel formwork offers cost-effective and sustainable advantages, further contributing to the long-term structural integrity of the constructed building.

- Q: How does steel formwork help in achieving accurate dimensions and shapes?

- Steel formwork helps in achieving accurate dimensions and shapes by providing a strong and rigid structure that holds the concrete in place during the curing process. This prevents any movement or deformation of the concrete, ensuring that it sets in the desired shape and size. The precise fabrication and assembly of steel formwork also allow for easy adjustment and customization, enabling accurate measurements and achieving the desired dimensions of the final structure.

- Q: How does steel formwork affect the overall aesthetics of a concrete structure?

- The overall aesthetics of a concrete structure can be significantly influenced by the use of steel formwork. Utilizing steel as a material for formwork offers numerous advantages that directly contribute to enhancing the visual appeal of the final concrete product. To begin with, the concrete surface can achieve a smooth and uniform finish through the use of steel formwork. The rigid nature of steel ensures that there are no imperfections or irregularities present on the formwork, resulting in a flawless and visually pleasing concrete structure. This is particularly important for architectural elements that aim for a sleek and polished appearance. Additionally, steel formwork allows for greater flexibility in design. By utilizing steel, it becomes possible to create complex and intricate shapes, curves, and patterns that can transform a concrete structure into a piece of art. The malleability of steel enables architects and designers to push the boundaries of creativity, resulting in visually stunning concrete structures that stand out. Moreover, steel formwork offers excellent dimensional stability. It can withstand the pressure exerted by the fresh concrete, ensuring that the formwork maintains its shape and integrity throughout the pouring and curing process. This stability prevents any deformations or distortions in the concrete, resulting in a consistent and visually appealing appearance. Furthermore, steel formwork provides superior strength and durability. This allows for the construction of larger and taller concrete structures, which can be visually impressive and impactful. The robustness of steel formwork ensures that the concrete structure remains structurally sound and visually appealing for an extended period of time. In conclusion, steel formwork plays a crucial role in enhancing the aesthetics of a concrete structure. Its ability to provide a smooth finish, offer design flexibility, maintain dimensional stability, and provide strength contributes to the creation of visually pleasing and architecturally impressive buildings. Whether it is a high-rise tower, an intricate bridge, or an iconic landmark, steel formwork helps elevate the overall aesthetics and visual impact of the concrete structure.

- Q: Can steel formwork be used for precast concrete elements?

- Yes, steel formwork can be used for precast concrete elements. Steel formwork is a popular choice for precast concrete fabrication due to its durability and reusability. It provides a strong and rigid structure that can withstand the pressure of wet concrete during casting and the weight of the hardened concrete after curing. Steel formwork also offers a smooth and consistent finish to the precast elements, ensuring high-quality and precise results. Additionally, steel formwork can be easily assembled and disassembled, allowing for efficient production and easy transportation of precast elements.

- Q: Are there any fire safety considerations when using steel formwork?

- When using steel formwork, it is crucial to take fire safety into account. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. However, it can lose its strength and structural integrity in high temperatures during a fire, potentially leading to structural failure, collapse, and the risk of injuries or fatalities. To mitigate these risks, it is necessary to implement proper fire safety measures. Considerations include: 1. Fire-resistant coatings: Applying fire-resistant coatings to the steel formwork helps protect it from heat and reduces the risk of structural failure during a fire. These coatings can offer additional fire resistance and be rated for specific fire durations. 2. Adequate fire protection systems: Installing and maintaining fire protection systems, such as sprinklers, fire extinguishers, and fire alarms, is essential for early fire detection and suppression. This prevents the fire from reaching the steel formwork and minimizes structural damage. 3. Fire-resistant barriers: Installing fire-resistant barriers, like fire-rated walls or partitions, contains the spread of fire and provides extra protection to the steel formwork. These barriers limit exposure to high temperatures and minimize the risk of structural failure. 4. Regular inspections and maintenance: Regularly inspecting the steel formwork for damage or corrosion is crucial to identify potential weak points that compromise its fire resistance. Promptly addressing any issues and repairing or replacing damaged sections is necessary. 5. Adequate fire escape routes: Ensuring accessible and well-marked fire escape routes near the steel formwork is vital for workers' safety in case of a fire. These routes should be obstruction-free and easily accessible for quick evacuation. Implementing these fire safety considerations significantly reduces the risk of structural failure and injuries associated with steel formwork. It is important to adhere to local building codes and regulations and consult fire safety professionals to ensure appropriate fire protection measures are in place.

- Q: How does steel formwork handle different concrete curing time requirements?

- Steel formwork proves to be a versatile and durable choice for construction projects, including those involving concrete structures. In terms of managing diverse concrete curing time needs, steel formwork presents numerous advantages. To begin with, steel formwork establishes a sturdy and secure framework for pouring concrete. This guarantees that the concrete remains in place and retains its desired shape throughout the curing process. Irrespective of the required curing time, steel formwork effectively withstands the weight and pressure exerted by the concrete, preventing any distortion or collapse. Furthermore, steel formwork boasts high adjustability and customizability. It can be easily modified to accommodate varying curing time requirements. For instance, if a specific section of concrete necessitates a lengthier curing time, supplementary support can be added to the steel formwork, providing extra strength and stability. Conversely, if a section requires a shorter curing time, the steel formwork can be adjusted accordingly to expedite the curing process. In addition, steel formwork possesses excellent heat conductivity properties. This facilitates efficient dissipation of heat during concrete curing. Different concrete mixes may generate heat at varying rates during hydration, and steel formwork assists in maintaining consistent curing temperatures. This proves particularly advantageous when dealing with concrete structures that demand specific curing temperatures. Moreover, steel formwork is reusable and capable of enduring multiple casting cycles. Consequently, it can be utilized for diverse projects with varying concrete curing time requirements, making it a cost-effective option. The durability and strength of steel formwork ensure its longevity, enabling contractors to adapt to different curing time needs without the need for constant replacement. In conclusion, steel formwork proves to be highly suitable for managing different concrete curing time requirements. Its stability, adjustability, heat conductivity, and reusability render it an ideal selection for construction projects of varying scales and complexities. Whether the concrete necessitates a longer or shorter curing time, steel formwork provides the essential support and flexibility to ensure successful curing and the creation of robust and enduring concrete structures.

- Q: Can steel formwork be used for sports complex construction projects?

- Yes, steel formwork can be used for sports complex construction projects. Steel formwork is a versatile and durable option for creating temporary molds or structures for casting concrete. Its strength and flexibility make it suitable for various construction projects, including sports complexes. Steel formwork can provide the necessary support and stability required during the construction process, ensuring the efficient and accurate placement of concrete in complex shapes and designs.

- Q: How does steel formwork affect the overall safety of a construction project?

- Steel formwork can have a significant impact on the overall safety of a construction project. Firstly, steel formwork provides a strong and stable structure for concrete pouring, ensuring that the concrete is properly contained and supported during the curing process. This eliminates the risk of concrete collapse or deformation, which can be hazardous to workers and the overall stability of the structure. Additionally, steel formwork is known for its durability and load-bearing capacity. It can withstand heavy loads and pressures, reducing the chances of formwork failure or collapse. This enhances the safety of workers who might be working on or around the formwork, as they can have confidence in its stability. Moreover, steel formwork is designed with safety features such as handrails, walkways, and ladder access points, which facilitate safe and easy access for workers during construction activities. These features minimize the risk of falls and accidents, promoting a safer working environment. Furthermore, steel formwork allows for precise and accurate construction, resulting in a higher quality finished product. This reduces the likelihood of structural defects or weaknesses that could compromise the safety of the building. Steel formwork also provides a smooth and even surface, reducing tripping hazards and facilitating safer movement on the construction site. Lastly, steel formwork is reusable and can be easily dismantled and relocated, reducing waste and minimizing environmental impact. This not only contributes to sustainability but also reduces the risks associated with handling and disposing of traditional formwork materials. In conclusion, steel formwork positively impacts the overall safety of a construction project by providing a robust structure, ensuring stability, offering safety features, enabling precise construction, reducing waste, and promoting a safer working environment.

- Q: Can steel formwork be used for both interior and exterior concrete structures?

- Yes, steel formwork can be used for both interior and exterior concrete structures. Steel is a versatile material that offers exceptional strength and durability, making it suitable for various construction applications. When used as formwork, steel provides a rigid and stable framework that can withstand the pressure exerted by fresh concrete during pouring and curing. This makes it ideal for creating both interior and exterior concrete structures. Steel formwork is commonly used for constructing walls, columns, beams, slabs, and other structural elements in buildings and infrastructure projects. Its robustness allows it to withstand harsh weather conditions and other environmental factors, making it suitable for exterior structures. Additionally, steel formwork can be easily reused multiple times, which makes it a cost-effective choice for both interior and exterior projects. Furthermore, steel formwork offers flexibility in design and can be easily customized to meet specific project requirements. It can be easily assembled and disassembled, allowing for efficient construction processes. The smooth surface of steel formwork also produces high-quality finishes on concrete structures. However, it is important to note that steel formwork requires proper maintenance to ensure its longevity and prevent corrosion. Regular inspections, cleaning, and the application of protective coatings are necessary to maintain the integrity of the formwork. In conclusion, steel formwork is a versatile and reliable choice for both interior and exterior concrete structures. Its strength, durability, and flexibility make it suitable for a wide range of construction projects, providing efficient and high-quality results.

Send your message to us

Stair tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords