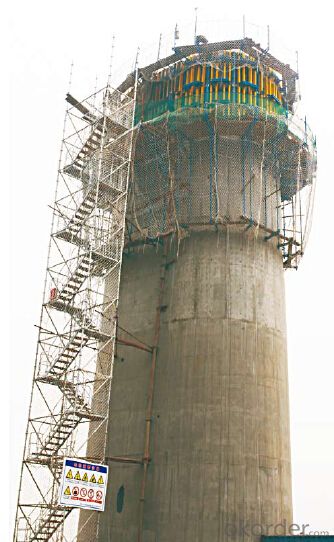

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: How does steel formwork accommodate for different concrete compaction methods?

- Steel formwork accommodates for different concrete compaction methods by providing a rigid and stable structure that can withstand the pressure and vibrations generated during compaction. The steel panels and frames used in formwork are designed to be strong and durable, ensuring that they can handle the forces exerted by different compaction techniques such as vibration, tamping, or mechanical compaction. Additionally, steel formwork can be easily adjusted or customized to suit specific compaction requirements, allowing for precise shaping and consolidation of the concrete.

- Q: How are steel formwork panels connected together?

- To create a sturdy and stable structure for pouring concrete, steel formwork panels are joined together using various methods. One commonly employed technique involves the use of steel pins or bolts, which are inserted into pre-drilled holes in the panels. These pins or bolts are then tightened or secured with nuts, ensuring a firm connection between the panels. Another approach involves the utilization of clamps or couplers, which are positioned along the edges of the panels and tightened to hold them in place. These clamps or couplers can be easily adjusted or removed, allowing for flexibility in the formwork system. Furthermore, certain steel formwork panels possess interlocking mechanisms like slots or hooks, which enable effortless alignment and connection. These interlocking features facilitate a seamless connection between the panels, resulting in a smooth and uninterrupted surface for pouring concrete. In conclusion, the connection of steel formwork panels is vital for preserving the integrity and stability of the formwork system during the concrete pouring process. The chosen method of connection depends on the specific design and requirements of the project, as well as the type of steel formwork being utilized.

- Q: How does steel formwork affect the overall sound insulation of the structure?

- The overall sound insulation of a structure is not directly influenced by steel formwork. The main purpose of steel formwork is to temporarily support and shape the concrete during construction. It is commonly used for concrete walls, slabs, columns, and beams. The sound insulation of a structure primarily depends on the materials used for walls, floors, and ceilings, as well as the design and construction techniques employed. These factors play a significant role in the transmission of sound waves and the overall acoustic performance of the building. Although steel formwork itself does not possess inherent sound insulation properties, it can indirectly impact the sound insulation of a structure during the construction phase. Improper installation or inadequate securing of the formwork may result in gaps or cracks in the concrete, which can compromise the sound insulation performance of the finished structure. However, it is essential to note that any potential impact on the sound insulation of the structure caused by steel formwork is temporary and can be resolved in subsequent stages of construction. This can be achieved by incorporating suitable acoustic insulation materials or employing soundproofing techniques. In conclusion, steel formwork does not directly affect the overall sound insulation of a structure. The sound insulation of a building is primarily determined by the materials and construction techniques utilized for walls, floors, and ceilings. Proper installation and subsequent measures can address any temporary impact on sound insulation caused by steel formwork during the construction process.

- Q: Are there any environmental benefits to using steel formwork?

- Using steel formwork in construction projects has numerous environmental benefits. Firstly, steel formwork is highly durable and can be reused multiple times, thereby minimizing the need for new formwork materials. This greatly reduces construction waste, as traditional materials like timber are often discarded after a single use. By opting for steel formwork, construction companies can decrease their environmental impact by reducing the amount of waste sent to landfills. In addition, steel formwork is recyclable, meaning that it can be recycled and repurposed into new steel products at the end of its lifecycle. This helps conserve natural resources and decrease the demand for raw materials. Moreover, the energy required to recycle steel is significantly lower than that needed for producing new steel, resulting in reduced greenhouse gas emissions. Steel formwork also offers advantages in terms of energy efficiency. Compared to traditional materials, it requires less energy for manufacturing and transportation, resulting in lower carbon emissions. Furthermore, its high strength and rigidity enable the construction of slender and lightweight structures, reducing material consumption and subsequently lowering energy requirements for heating, cooling, and lighting in buildings. Lastly, steel formwork is resistant to moisture, fire, and pests, minimizing the need for chemical treatments and preservatives that can harm the environment. This makes it a more sustainable option and reduces negative impacts on ecosystems and human health. Overall, utilizing steel formwork in construction projects provides several environmental benefits, such as reduced waste generation, increased recycling opportunities, energy efficiency, and reduced reliance on harmful chemicals. By choosing steel formwork, construction companies can contribute to a more sustainable and environmentally-friendly construction industry.

- Q: What are the safety considerations when working with steel formwork?

- To ensure the workers' well-being and the project's success, it is important to consider several safety factors when working with steel formwork. The foremost priority is to provide comprehensive training to all workers involved in handling and installing steel formwork. This training should cover safe handling techniques for heavy steel panels and proper assembly and dismantling procedures. Additionally, workers should be educated on the potential risks associated with steel formwork, such as falling objects and pinch points, and how to mitigate these risks. Another crucial safety consideration is the use of appropriate personal protective equipment (PPE). It is necessary to supply workers with and enforce the use of PPE such as hard hats, safety glasses, steel-toed boots, and gloves to safeguard against potential hazards. It is also essential to ensure that the PPE is in good condition and properly fitted for each worker. Maintaining safety on a steel formwork site relies heavily on proper planning and organization. This entails conducting thorough risk assessments, identifying potential hazards, and implementing control measures to minimize risks. Establishing designated walkways and clear access routes is vital to prevent tripping hazards and ensure safe movement around the site. Regular inspections of the steel formwork system are necessary to identify any signs of damage or deterioration. Prompt repair or replacement of any damaged or defective components is crucial to maintain the formwork's structural integrity and safety. Finally, effective communication and coordination among workers are essential for a safe working environment. It is important to establish clear communication channels and procedures to ensure that everyone is informed about potential hazards and can promptly report any safety concerns. By prioritizing training, providing proper PPE, planning and organizing the work site, conducting regular inspections, and promoting effective communication, the safety considerations when working with steel formwork can be effectively addressed, reducing the risk of accidents and injuries.

- Q: Types of building templates? What is clear water template?

- Wood plywood (water templates): currently widely used in the solid wood plywood formwork, should promote the use of wood covered plywood. Commonly used in Guangdong area of Eucalyptus wood membrane.

- Q: How does steel formwork handle formwork stability during concrete pouring?

- Steel formwork provides excellent formwork stability during concrete pouring due to its high strength and rigidity. It can withstand the pressure and weight of the fresh concrete without deformation or collapse, ensuring the desired shape and structure of the concrete elements. Additionally, steel formwork can be easily adjusted and secured in place, allowing for precise alignment and stability during the pouring process.

- Q: What is the difference between the steel template and the wood template? When to use steel formwork? When to use a wooden template?Now what kind of use

- Can use a combination of steel templates can also be used in large format steel formwork

- Q: Can steel formwork be used for curved or irregular-shaped structures?

- Indeed, curved or irregular-shaped structures can be constructed using steel formwork. Unlike conventional timber formwork, steel formwork boasts enhanced flexibility and strength, rendering it ideal for intricate shapes and designs. With steel formwork, it is effortless to bend or fabricate it into any desired shape, facilitating the construction of curved walls, columns, and slabs. Furthermore, steel formwork delivers exceptional support and stability, guaranteeing the precision and accuracy of the eventual structure. Its durability and reusability further contribute to its cost-effectiveness in projects involving curved or irregular-shaped structures.

- Q: How does steel formwork contribute to improved construction quality?

- Steel formwork is a construction technique that involves the use of steel sheets or panels to create temporary molds for concrete structures. It is widely recognized for its ability to contribute to improved construction quality in several ways. Firstly, steel formwork offers high precision and accuracy in shaping concrete structures. The steel panels are manufactured to precise dimensions, ensuring that the final concrete structure is built according to the desired specifications. This level of precision minimizes the risk of errors and inconsistencies, resulting in a higher-quality construction. Secondly, steel formwork provides excellent durability and stability. Unlike traditional wooden formwork, steel formwork can withstand extreme weather conditions, heavy loads, and repeated use without warping or deforming. This durability ensures that the formwork remains intact throughout the construction process, preventing any potential issues that may arise from a compromised formwork system. Additionally, steel formwork allows for faster construction cycles compared to other formwork materials. The ease of assembly and disassembly, along with the ability to reuse the formwork on multiple projects, significantly reduces construction time. This efficiency not only saves construction companies time but also minimizes disruptions to neighboring sites and reduces costs associated with extended construction periods. Moreover, steel formwork enhances construction quality by providing a smooth and uniform finish to concrete structures. The steel panels create a seamless mold, eliminating the need for excessive remedial work such as plastering or patching. This results in a visually appealing and aesthetically pleasing final product, which is crucial for projects that require high-quality finishes. Furthermore, steel formwork allows for greater flexibility in design and construction. The modular nature of steel panels enables architects and engineers to create complex and intricate structures with ease. This versatility enables the construction of unique and innovative designs, enhancing the overall quality and visual appeal of the project. In conclusion, steel formwork significantly contributes to improved construction quality by providing high precision, durability, efficiency, and flexibility. Its ability to create accurate molds, withstand external forces, reduce construction time, and produce seamless finishes ensures that the final concrete structures meet the highest standards of quality and durability.

Send your message to us

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords