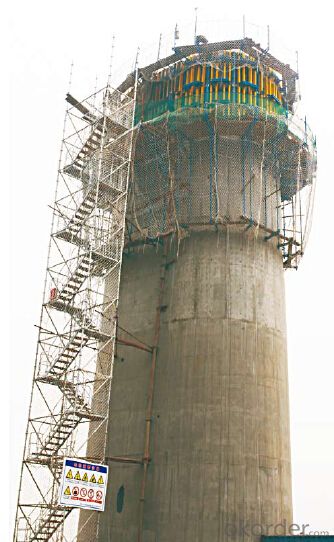

Stair tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: How does steel formwork handle concrete setting time and curing temperature?

- Steel formwork is a preferred choice for handling concrete setting time and curing temperature due to its excellent heat transfer properties and durability. Steel, being a good conductor of heat, helps in dissipating the heat generated during the hydration process of concrete, thus accelerating its setting time. This allows for a faster construction process and reduces the overall project timeline. Additionally, steel formwork can withstand high curing temperatures without deforming or deteriorating. This is particularly important in cases where concrete requires high-temperature curing to achieve the desired strength and durability. Steel's ability to withstand high temperatures ensures that the formwork remains intact and stable, providing the necessary support to the concrete during the curing process. Furthermore, steel formwork's strength and rigidity prevent any deformation or movement during the concrete setting and curing stages. This is crucial for maintaining the desired shape, size, and surface finish of the concrete structure. The use of steel formwork ensures that the concrete remains in place and does not experience any undesirable shifts or displacements during the curing process. In conclusion, steel formwork is an ideal choice for handling concrete setting time and curing temperature due to its excellent heat transfer properties, ability to withstand high temperatures, and its strength and rigidity. Its usage facilitates faster setting times, allows for high-temperature curing, and ensures the stability and integrity of the concrete structure during the curing process.

- Q: How does steel formwork affect the concrete finish?

- Steel formwork can have a significant impact on the concrete finish. Firstly, steel formwork provides a smoother and more uniform surface compared to other types of formwork materials such as wood or plastic. This can result in a smoother and more aesthetically pleasing concrete finish. Additionally, steel formwork provides a higher level of dimensional accuracy and stability during the concrete pouring and curing process. This means that the concrete is less likely to shrink or warp, resulting in a more precise and even finish. Furthermore, steel formwork allows for tighter joints and fewer seams, which can minimize the occurrence of surface imperfections such as cracks or air pockets. This is particularly important for achieving a high-quality finish in architectural or decorative concrete applications. Moreover, steel formwork provides better resistance to moisture and chemicals, reducing the risk of staining or discoloration on the concrete surface. It also offers a higher level of durability, ensuring that the formwork remains intact throughout the entire concrete pouring process, resulting in a smoother and more consistent finish. In summary, the use of steel formwork positively affects the concrete finish by providing a smoother surface, better dimensional accuracy, fewer surface imperfections, improved resistance to moisture and chemicals, and enhanced durability.

- Q: Is steel formwork resistant to corrosion?

- Yes, steel formwork is resistant to corrosion.

- Q: Are all steel plates used for beam slab prefabrication

- If all steel plates are used for precast beam and slab, the shape of prefabricated components should be adopted

- Q: Can steel formwork be used for commercial construction projects?

- Yes, steel formwork can be used for commercial construction projects. Steel formwork offers durability, strength, and the ability to withstand heavy loads, making it a suitable choice for large-scale construction projects such as commercial buildings. It provides a stable and reusable solution that allows for efficient and precise concrete placement, ensuring high-quality results.

- Q: What is the maximum height that steel formwork can be used for?

- The maximum height that steel formwork can be used for depends on several factors such as the structural design and engineering requirements of the construction project, the type of steel formwork being used, and the specific conditions of the site. Steel formwork is known for its high strength and durability, making it suitable for constructing tall structures. However, it is important to consider the weight and stability of the formwork system as it increases in height. In general, steel formwork can be used for constructing structures of varying heights, ranging from low-rise buildings to high-rise skyscrapers. The maximum height will often be determined by engineering calculations and considerations, including the weight-bearing capacity of the formwork system, the lateral stability requirements, and the ability to withstand external forces such as wind loads. For taller structures, additional support mechanisms and reinforcement may be required to ensure the stability and integrity of the formwork system. These may include the use of braces, tie rods, and other structural elements to prevent deflection and maintain the desired shape of the concrete during the pouring and curing process. It is crucial to consult with experienced structural engineers and formwork specialists to assess the specific requirements and limitations of each construction project. They will be able to determine the maximum height that steel formwork can be safely used for, taking into account all relevant factors and ensuring the structural integrity and safety of the construction process.

- Q: Can steel formwork be used in areas with high chemical exposure?

- Steel formwork can be used in areas with high chemical exposure, but it may not be the most ideal choice. Steel is generally a durable and strong material, but it can be susceptible to corrosion when exposed to certain chemicals. If the chemicals present in the area are known to corrode steel, it is recommended to consider alternative formwork materials such as plastic or aluminum, which may be more resistant to chemical exposure. Additionally, protective coatings or treatments can be applied to steel formwork to enhance its resistance to chemicals. However, it is important to evaluate the specific chemicals and their concentration in the area to determine the most suitable formwork material for the project.

- Q: How does steel formwork handle different concrete surface repair techniques?

- Steel formwork is highly versatile and can easily accommodate various concrete surface repair techniques. Its strong and durable structure allows for the application of techniques such as surface grinding, shot blasting, or sandblasting to remove damaged or deteriorated concrete. Additionally, steel formwork provides a smooth and stable surface, enhancing the effectiveness of techniques like patching, skim coating, or the application of bonding agents. Overall, steel formwork is compatible with a wide range of concrete surface repair techniques, making it a reliable choice for handling such repairs.

- Q: How does steel formwork compare to timber formwork?

- Construction projects often prefer steel formwork over timber formwork for several reasons. Firstly, steel formwork is highly durable and long-lasting compared to timber formwork. Steel is a resilient material that can withstand heavy loads and harsh weather, making it ideal for multiple uses and reducing the need for frequent replacements. In terms of strength, steel formwork provides greater structural integrity and stability. It can handle higher concrete pressures, allowing for the construction of taller and more complex structures. This is particularly advantageous for high-rise buildings or projects that require large spans. Steel formwork also offers superior dimensional accuracy and consistency. Unlike timber, it does not warp or distort over time, ensuring that the final concrete structure maintains its intended shape and dimensions. This saves time and effort during construction, as fewer adjustments or corrections are necessary. Moreover, steel formwork is easier to clean and maintain. It does not absorb moisture or attract pests like timber does, reducing the risk of deterioration or contamination. Additionally, steel formwork can be easily reused multiple times, making it a more sustainable and cost-effective option in the long run. However, it is important to note that steel formwork generally requires more specialized equipment and skilled labor for assembly and disassembly compared to timber formwork. This may result in higher initial costs and longer setup times for projects. Furthermore, steel formwork may not be suitable for certain applications where weight is a concern, as it is generally heavier than timber. Overall, while both steel and timber formwork have their pros and cons, steel formwork is often preferred in construction due to its durability, strength, dimensional accuracy, and ease of maintenance.

- Q: Are there any specialized tools or equipment required for steel formwork?

- Yes, there are specialized tools and equipment required for steel formwork. Some of these include steel formwork panels, formwork ties, formwork clamps, formwork brackets, formwork props, and formwork beams. These tools and equipment are specifically designed to handle the heavy loads and provide stability during concrete pouring and curing processes.

Send your message to us

Stair tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords