Adjustable Arced for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

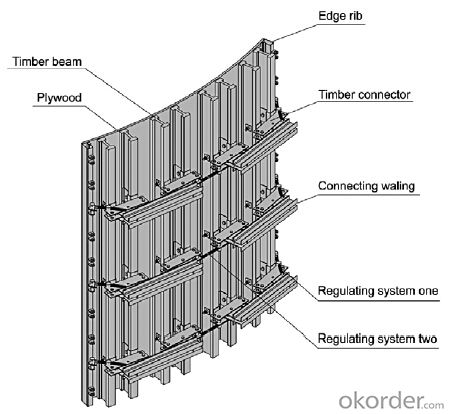

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: What are the weight limits for steel formwork panels?

- The weight limits for steel formwork panels can vary depending on their size, thickness, and design. It is best to refer to the manufacturer's specifications or guidelines for the specific weight limits of the steel formwork panels being used.

- Q: Can steel formwork be used in bridge construction projects?

- Yes, steel formwork can be used in bridge construction projects. Steel formwork refers to the temporary structure used to support and shape the concrete during the construction process. It is commonly used in various construction projects, including bridges. Steel formwork provides several advantages in bridge construction, such as high strength, durability, and resistance to deformation. It can withstand the weight of the concrete and other construction materials, ensuring the stability and integrity of the bridge structure. Additionally, steel formwork offers flexibility in creating complex bridge designs, allowing for the construction of different types of bridges, such as arch bridges, cable-stayed bridges, and suspension bridges. The use of steel formwork in bridge construction projects helps to streamline the construction process, improve efficiency, and ensure the quality of the final bridge structure.

- Q: Are there any specific considerations for using steel formwork in earthquake-prone areas?

- Yes, there are specific considerations for using steel formwork in earthquake-prone areas. Steel formwork is known for its strength and durability, which is why it is often preferred in seismic regions. However, there are several factors that need to be taken into account when using steel formwork in earthquake-prone areas: 1. Flexibility: Steel formwork should be designed to have the necessary flexibility to withstand seismic forces. It should be able to absorb and dissipate the energy generated during an earthquake, reducing the risk of structural damage. 2. Connection details: The connection details between the steel formwork components should be carefully designed and engineered to ensure proper load transfer and resistance to seismic forces. Special attention should be given to the joints and connections to prevent failure or collapse during an earthquake. 3. Reinforcement: Additional reinforcement might be required to enhance the strength and stiffness of the steel formwork system. This reinforcement can be in the form of additional steel bars, cross bracing, or diagonal struts to provide increased resistance against lateral forces. 4. Anchorage: Proper anchorage of the steel formwork to the supporting structure is crucial in earthquake-prone areas. The formwork should be securely anchored to the foundation or the structural elements to prevent displacement or movement during an earthquake. 5. Inspection and maintenance: Regular inspection and maintenance of the steel formwork system are essential in earthquake-prone areas. Any damage or wear should be identified and repaired promptly to ensure the integrity and stability of the formwork system. 6. Compliance with building codes: It is important to ensure that the steel formwork system complies with the local building codes and regulations for seismic design. These codes provide guidelines and requirements for the design, installation, and use of formwork in earthquake-prone areas. By considering these specific factors, using steel formwork in earthquake-prone areas can provide enhanced structural resilience and contribute to the overall safety and durability of the construction project.

- Q: What are the advantages and disadvantages of the application of the steel formwork and the plywood formwork in the construction?

- Economic aspect: the steel formwork one-time investment cost is high, but the turnover number is more; the wood template cost is low, but the turnover number is less

- Q: What are the considerations for designing steel formwork systems?

- Some considerations for designing steel formwork systems include the load-bearing capacity of the steel, the desired shape and size of the forms, the ease of assembly and disassembly, the compatibility with other construction methods, the cost-effectiveness, and the durability of the materials used. Additionally, factors such as the required finishes, the need for reusability, and the safety precautions should also be taken into account during the design process.

- Q: What are the typical deflection limits for steel formwork systems?

- The deflection limits of steel formwork systems can vary depending on various factors, such as the project's specific design and application requirements. However, there are commonly followed general guidelines. In most cases, the deflection limits for steel formwork systems are determined based on the span length and the applied load. Typically, deflection limits are restricted to L/360 or L/240, where L represents the span length of the formwork. For instance, if the formwork's span length is 10 feet, the deflection limit would be L/360, which is approximately 0.028 feet or 0.34 inches. This means that the maximum allowable deflection for this formwork system would be 0.34 inches, ensuring stability and minimal deformation under the load. It should be noted that these deflection limits may be adjusted according to project requirements or industry standards. In high-rise construction projects, stricter deflection limits may be enforced to ensure the formwork system's structural integrity and overall safety. Ultimately, careful consideration and evaluation of deflection limits are necessary during the design and construction process of steel formwork systems. Consulting a structural engineer or referring to relevant industry standards can provide more accurate and specific deflection limits for a given system.

- Q: What are the considerations when designing steel formwork for underground parking structures?

- When designing steel formwork for underground parking structures, several key considerations should be taken into account. Firstly, the formwork must be able to withstand the heavy loads and pressures exerted by the surrounding soil and any potential water infiltration. It is crucial to ensure the strength, stability, and durability of the formwork system to prevent any structural failures or collapses. Additionally, careful attention should be paid to the formwork's waterproofing capabilities. Adequate waterproofing measures, such as the use of sealants or membranes, must be incorporated to protect the structure against potential water ingress, which could lead to corrosion and long-term damage. Moreover, the design should allow for efficient and safe construction. This includes considering factors such as ease of assembly and disassembly, ensuring proper access and working space for construction workers, and incorporating appropriate safety measures to prevent accidents during the formwork installation and removal processes. Lastly, the formwork design should also take into consideration the desired architectural and aesthetic elements of the parking structure. This may involve incorporating specific finishes, textures, or patterns on the exposed concrete surfaces, which can enhance the overall visual appeal of the underground parking facility. Overall, the considerations when designing steel formwork for underground parking structures revolve around ensuring structural integrity, waterproofing capabilities, construction efficiency, safety, and meeting the desired architectural requirements.

- Q: How does steel formwork compare to aluminum formwork in terms of performance?

- Steel formwork and aluminum formwork are two commonly used materials in the construction industry for creating temporary molds or structures that hold concrete in place until it hardens. While both materials have their advantages and disadvantages, it is important to consider their performance aspects when comparing them. In terms of performance, steel formwork is known for its strength and durability. It has a high load-bearing capacity, making it suitable for heavy-duty applications. Steel formwork can withstand extreme weather conditions, rough handling, and repetitive use without significant wear and tear. The rigidity of steel formwork ensures that the structure maintains its shape during the concrete pouring process, resulting in accurate and precise finishes. Additionally, steel formwork allows for easy customization and modification to meet specific project requirements. On the other hand, aluminum formwork is preferred for its lightweight nature, which makes it easy to handle, transport, and assemble. The lightweight nature of aluminum formwork reduces labor costs and speeds up construction time. It also boasts excellent corrosion resistance, making it suitable for projects near coastal areas or in humid environments. Furthermore, aluminum formwork provides a smooth surface finish on the concrete, requiring minimal or no surface treatment. While both steel and aluminum formwork have their own advantages, the choice between the two depends on the specific requirements of the project. If the project involves heavy loads or requires a high number of reuses, steel formwork should be considered due to its superior strength and durability. However, if the project demands quick assembly, easy handling, and a smooth surface finish, aluminum formwork would be a better choice. Ultimately, the selection of steel or aluminum formwork should be based on a careful evaluation of the project's needs, budget, and timeline. A thorough assessment of the performance aspects, as well as other factors such as cost, maintenance, and environmental impact, will help determine the most suitable formwork material for a particular construction project.

- Q: How does steel formwork affect the overall construction schedule?

- Steel formwork can have a positive impact on the overall construction schedule. Its durability and reusability allow for faster and more efficient construction processes. The quick assembly and disassembly of steel formwork facilitate faster concrete pouring and curing times, leading to shorter construction cycles. Additionally, the uniformity and accuracy of steel formwork help in achieving consistent quality, reducing the need for rework and thus saving time in the construction schedule.

- Q: How does steel formwork affect the overall quality of the concrete structure?

- The overall quality of a concrete structure is greatly influenced by steel formwork. Several factors contribute to this quality: 1. Precise Dimensions: Steel formwork guarantees accurate dimensions for the concrete structure. It maintains a rigid framework during pouring and curing, preventing any deformations or distortions. This precision in dimensions enhances the overall strength, stability, and durability of the structure. 2. Smooth Surface Finish: Steel formwork assists in achieving a uniform and smooth surface finish for the concrete. The smoothness of the formwork translates into a smooth concrete surface, reducing the need for additional finishing work. Not only does this improve the aesthetics, but it also enhances the durability and resistance to wear and tear. 3. Strength and Load-bearing Capacity: Steel formwork is renowned for its high strength and load-bearing capacity. This strength enables it to withstand the pressure exerted by the concrete during pouring and curing. A robust formwork ensures proper support for the concrete structure, enabling it to withstand the intended loads. This contributes to the overall integrity and safety of the building. 4. Cost-effective Reusability: Steel formwork is a cost-effective option due to its reusability. Its durability allows for multiple uses, reducing the need for frequent replacements. This not only saves money but also reduces construction waste. By employing steel formwork, contractors can achieve high-quality concrete structures without compromising on cost or environmental impact. In conclusion, steel formwork significantly impacts the overall quality of a concrete structure through its provision of precise dimensions, smooth surface finish, strength, load-bearing capacity, reusability, and cost-effectiveness. Proper utilization of steel formwork ensures compliance with required standards, enhances durability, and guarantees occupant safety.

Send your message to us

Adjustable Arced for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches