Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

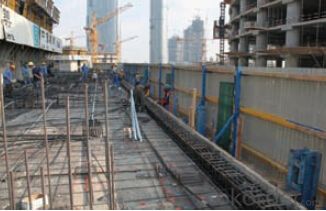

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: Can steel formwork be easily modified or adjusted during construction?

- Yes, steel formwork can be easily modified or adjusted during construction. Steel formwork is known for its flexibility and adaptability, allowing for quick and convenient adjustments as per the project requirements. Steel formwork systems are designed to be modular, which means they can be easily assembled and disassembled, allowing for easy modification or adjustment of the formwork structure. Additionally, steel formwork can be easily cut, welded, or bolted together to create custom formwork shapes or sizes. This versatility of steel formwork makes it a preferred choice in construction projects where modifications or adjustments are frequently required.

- Q: What types of concrete structures can be built using steel formwork?

- Steel formwork is a versatile construction tool that has the capability to build a variety of concrete structures. Some examples of common structures that can be created using steel formwork are: 1. Walls: Steel formwork can be utilized to construct both retaining walls and load-bearing walls. It provides the necessary support to hold the concrete in place until it sets and gains its strength. Steel formwork allows for the construction of walls with different shapes and sizes, such as straight, curved, or inclined walls. 2. Columns: For constructing columns of varying heights and diameters, steel formwork is the ideal choice. It offers a strong and stable framework to hold the concrete in place while it cures. Steel formwork can be easily adjusted to accommodate various column dimensions, making it suitable for both small and large-scale construction projects. 3. Beams and Slabs: Beams, which are horizontal structural members that support the structure above, and slabs, which form the floors or roofs of a building, can also be constructed using steel formwork. Steel formwork allows for the construction of beams and slabs with different shapes and sizes, including rectangular, circular, or even curved configurations. 4. Bridges and Tunnels: Bridges and tunnels commonly rely on steel formwork during construction. It enables the creation of complex structural elements with high precision and accuracy. Steel formwork systems are easily transportable and can be assembled on-site, making them an efficient choice for bridge and tunnel construction projects. 5. Staircases: Steel formwork can also be used to build staircases with various configurations, such as straight flights, spiral stairs, or helical stairs. It provides the necessary support to create the desired shape and geometry of the staircase. Steel formwork ensures the structural integrity of the staircase while the concrete sets and hardens. In summary, steel formwork is a flexible and durable solution for constructing a wide range of concrete structures. Its adaptability, strength, and ease of use make it an ideal choice for various construction projects, including residential buildings and large-scale infrastructure developments.

- Q: Can steel formwork be used for both residential and commercial projects?

- Steel formwork can serve both residential and commercial projects effectively. Renowned for its strength and capacity to bear heavy loads, steel formwork is a flexible and enduring choice extensively employed in construction. Its adaptability enables convenient customization to cater to diverse project demands, irrespective of whether they pertain to residential or commercial ventures. Among its merits are notable advantages like exceptional concrete finish, swift assembly, and extensive reusability. In both residential and commercial construction, steel formwork finds widespread application in foundations, walls, slabs, columns, and beams.

- Q: How does steel formwork contribute to the overall sustainability of the project?

- There are several ways in which steel formwork contributes to the overall sustainability of a project. Firstly, steel is an incredibly durable material that can withstand heavy loads and repeated use. This means that the same steel formwork can be used for multiple construction cycles, reducing the need for new formwork materials and minimizing waste. Moreover, steel formwork is highly adaptable and can easily be customized to meet various design requirements. This flexibility allows for efficient material usage and reduces the amount of construction waste generated. Furthermore, steel formwork is highly recyclable. When it reaches the end of its life cycle, it can be easily taken apart and recycled. This reduces the demand for new steel production and minimizes the environmental impact associated with mining and manufacturing new materials. Additionally, compared to traditional timber formwork, steel formwork offers better quality control. It provides precise and consistent dimensions, resulting in a final product of high accuracy and quality. This reduces the need for rework and ensures less material wastage. Lastly, the use of steel formwork can lead to shorter construction periods. Its quick assembly and disassembly allow for faster construction processes, reducing the overall energy consumption and carbon emissions associated with the project. To conclude, steel formwork contributes to the overall sustainability of a project through its durability, recyclability, versatility, and efficiency. By reducing waste, minimizing environmental impact, and improving construction processes, steel formwork helps create more sustainable and environmentally-friendly construction projects.

- Q: What are the weight limitations of steel formwork?

- The weight limitations of steel formwork depend on various factors such as the type and thickness of the steel used, the design of the formwork system, and the support structure. Generally, steel formwork is known for its high load-bearing capacity and can withstand significant weight. For example, typical steel formwork systems can support concrete loads ranging from 50 to 100 kN/m² (10 to 20 pounds per square foot). However, it is important to consult the manufacturer's specifications and guidelines for the specific formwork system being used as they may have their own weight limitations. Additionally, the weight limitations can also be influenced by the height and width of the formwork panels, the spacing and strength of the supporting beams or columns, and the reinforcement provided for added stability. In summary, steel formwork is known for its strength and ability to withstand considerable weight, but the weight limitations can vary depending on the specific formwork system and its design, as well as the support structure. It is crucial to follow the manufacturer's guidelines and consult with structural engineers to ensure safe and efficient use of steel formwork.

- Q: What are the different types of formwork bracing used with steel formwork?

- Steel formwork can be supported and stabilized using various types of bracing. These include: 1. Horizontal Bracing: Installed between vertical supports, this bracing provides stability and prevents lateral movement or deformation of the formwork. 2. Diagonal Bracing: By connecting vertical supports diagonally, this bracing adds stability, evenly distributes the load, and prevents twisting or buckling of the formwork. 3. Vertical Bracing: Installed between horizontal supports, this bracing supports the vertical members of the formwork system and prevents vertical movement or deformation. 4. Cross Bracing: This bracing combines horizontal and diagonal support, providing both lateral and diagonal stability. It is commonly used in larger structures or when increased stability is required. 5. Tie Rods: These rods connect the formwork panels and offer additional support. They are placed at regular intervals along the formwork and tightened to ensure that the formwork remains in place during concrete pouring. The selection of formwork bracing depends on project-specific requirements, such as the size and complexity of the structure, as well as the load-bearing capacity of the formwork system. It is crucial to design and install the bracing carefully to ensure the safety and stability of the formwork during construction.

- Q: Can steel formwork be used for both large and small construction projects?

- Yes, steel formwork can be used for both large and small construction projects. Steel formwork offers several advantages such as durability, strength, and reusability, which make it suitable for a wide range of projects. For large construction projects, steel formwork provides the necessary structural support to handle heavy loads and withstand the pressures of large-scale construction. Additionally, its ability to be easily assembled and disassembled allows for efficient construction processes. On the other hand, for small construction projects, steel formwork offers cost-effectiveness and flexibility. Its reusability allows for multiple uses, minimizing the need for additional formwork materials and reducing construction costs. Overall, steel formwork is a versatile option that can be adapted to meet the requirements of both large and small construction projects.

- Q: Is steel formwork suitable for projects with heavy concrete loads?

- Yes, steel formwork is suitable for projects with heavy concrete loads. Steel is a strong and durable material that can withstand the weight and pressure of heavy concrete loads without deformation or damage, making it an ideal choice for such projects.

- Q: How does steel formwork contribute to the overall accuracy of concrete placement?

- Steel formwork contributes to the overall accuracy of concrete placement in several ways. First and foremost, steel formwork provides a rigid and stable structure that ensures the concrete is poured and cured in the desired shape and dimensions. The steel panels are designed to be strong and resistant to deformation, which minimizes the risk of the formwork shifting or warping during the pouring process. Furthermore, steel formwork allows for precise control over the alignment and leveling of the formwork. The panels can be easily adjusted and secured in place, ensuring that the concrete is poured at the intended level and alignment. This is particularly important for projects that require a high level of accuracy, such as those involving intricate architectural designs or where precise measurements are critical. Additionally, steel formwork offers the advantage of reusability. Unlike traditional wooden formwork, which can only be used a limited number of times, steel formwork can be used repeatedly without compromising its structural integrity. This reusability factor contributes to cost-effectiveness and allows for consistent accuracy in concrete placement throughout multiple projects. Moreover, the smooth surface of steel formwork helps to achieve a high-quality finish on the concrete surface. The smoothness of the steel panels minimizes the risk of surface imperfections and ensures a consistent texture and appearance. This is particularly important for projects where the concrete will be left exposed, such as architectural features or decorative elements. In conclusion, steel formwork plays a crucial role in ensuring the overall accuracy of concrete placement. Its rigidity, adjustability, reusability, and smooth surface contribute to achieving precise dimensions, alignment, and finish, making it an indispensable tool for construction projects that require high levels of accuracy and quality.

- Q: Are there any safety precautions to consider when using steel formwork?

- When using steel formwork, it is important to consider several safety precautions. 1. Proper training is crucial. Workers must receive training on correct handling and assembly procedures. This includes understanding load capacity, installation techniques, and dismantling processes. 2. Regular inspection and maintenance are necessary to ensure the formwork's structural integrity. Any signs of damage should be immediately addressed and repaired. 3. Workers should wear appropriate personal protective equipment (PPE), such as helmets, safety goggles, gloves, and steel-toe boots. This protects them from potential hazards. 4. A secure and stable platform is essential for workers to access and work on the formwork. This may involve using scaffolding, ladders, or elevated work platforms that meet safety standards. 5. Fall protection measures must be implemented for working at heights. This may include installing guardrails, safety nets, or personal fall arrest systems. 6. Proper lifting techniques should be followed to prevent strain or muscle injuries. Mechanical lifting equipment can also help minimize accidents. 7. Clear communication and coordination among workers is vital. This includes establishing a chain of command, using hand signals or radios, and conducting regular safety meetings. By following these precautions, the risk of accidents, injuries, and damage can be significantly reduced when using steel formwork.

Send your message to us

Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords