Protection Platform for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

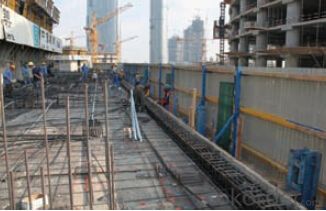

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: How does steel formwork handle different concrete surface reflectivity?

- Steel formwork is highly versatile and can easily handle different concrete surface reflectivity. The smooth and rigid nature of steel allows it to provide a consistent and even surface for concrete placement, regardless of the reflectivity of the concrete. This ensures that the concrete surface is uniform and free from any distortions or irregularities caused by variations in reflectivity. Additionally, steel formwork can be adjusted or modified to accommodate specific requirements, providing a reliable solution for handling different concrete surface reflectivity.

- Q: What are the weight limits for steel formwork panels?

- The weight limits for steel formwork panels can vary depending on their size, thickness, and design. It is best to refer to the manufacturer's specifications or guidelines for the specific weight limits of the steel formwork panels being used.

- Q: How does steel formwork handle formwork stripping and repositioning?

- Steel formwork is well-suited for handling formwork stripping and repositioning due to its inherent strength and durability. With steel formwork, the process of removing the formwork from the concrete structure is relatively easy and efficient. The steel panels or frames can be quickly detached and repositioned at the desired location, allowing for seamless reusability and adaptability. This flexibility and ease of handling make steel formwork a preferred choice for projects that require frequent formwork stripping and repositioning.

- Q: How is steel formwork supported during concrete pouring?

- Steel formwork is supported during concrete pouring by using props or scaffolding. These supports are strategically placed at regular intervals to provide stability and prevent any sagging or movement of the formwork. Additionally, adjustable bolts or wedges are used to ensure that the formwork remains level and in the desired position throughout the pouring process.

- Q: How does steel formwork handle formwork removal and storage?

- Steel formwork is known for its durability and strength, which makes it highly suitable for handling formwork removal and storage. When it comes to formwork removal, steel formwork can be easily disassembled and removed from the concrete structure. This is primarily due to the modular nature of steel formwork, which allows for easy dismantling and reassembly. Steel formwork systems often consist of standard-sized panels that can be quickly and efficiently removed by loosening the connecting bolts or clips. This process ensures that the formwork can be easily dismantled without causing damage to the concrete structure or the formwork itself. Additionally, the lightweight nature of steel formwork allows for easy handling during removal, reducing the risk of accidents or injuries. In terms of storage, steel formwork offers several advantages. Firstly, steel formwork can be stacked and stored in a compact manner, saving space in construction sites or storage facilities. The modular design of steel formwork panels allows for easy stacking and organization, ensuring that the formwork can be efficiently stored without taking up excessive space. Furthermore, steel formwork is less susceptible to damage from weather conditions compared to other types of formwork materials such as wood or plywood. Steel formwork can withstand exposure to rain, sunlight, and temperature fluctuations without warping, rotting, or deteriorating. This durability makes steel formwork a reliable option for long-term storage, as it can be reused multiple times without significant degradation. Overall, steel formwork provides a superior solution for formwork removal and storage. Its strength and durability allow for easy dismantling and removal, while its modular design and compact storage capabilities make it an ideal choice for efficient storage. With these advantages, steel formwork contributes to increased productivity and cost-effectiveness in construction projects.

- Q: How does steel formwork handle different concrete expansion properties?

- Steel formwork is a highly durable and rigid material that can easily handle different concrete expansion properties. Its strength and stiffness allow it to withstand the pressure exerted by expanding concrete without deforming or cracking. Additionally, steel formwork is typically designed with expansion joints or gaps, which provide sufficient space for the concrete to expand and contract without causing any structural issues. This ensures that the formwork remains intact and maintains its shape, allowing for successful concrete pouring and curing.

- Q: What materials are used in steel formwork construction?

- A sturdy and durable structure is typically created in steel formwork construction by using a combination of materials. The main material used is steel, which provides excellent strength and rigidity to support the weight and pressure of the concrete during casting. In addition to steel, other materials such as plywood or timber are used to construct the formwork panels. These panels are made of high-quality plywood or timber boards that are strong enough to bear the weight of the concrete without bending or warping. To enhance the formwork structure, steel bars or rods are strategically placed within the formwork for additional support. This prevents any deformation or collapse of the structure while pouring the concrete. Various connectors, fasteners, and accessories are also utilized in steel formwork construction. These include bolts, nuts, clamps, wedges, and pins, among others. These components securely join and hold the formwork panels and reinforcement bars together, ensuring a stable and rigid structure. Overall, steel formwork construction involves using steel, plywood or timber, reinforcement bars, and various connectors and accessories. These materials collaborate to create a robust and reliable formwork system capable of withstanding the pressures and forces exerted during the concrete casting process.

- Q: How does steel formwork affect the overall project budget and cost control?

- Steel formwork can have a significant impact on the overall project budget and cost control. While it tends to have a higher initial cost compared to other formwork systems, its durability and reusability can help offset this expense in the long run. Steel formwork also allows for faster construction and requires fewer labor hours, leading to potential cost savings in terms of reduced labor costs. Additionally, its accuracy and precision help minimize material wastage, further contributing to cost control.

- Q: Can steel formwork be used for concrete beams with varying cross-sections?

- Yes, steel formwork can be used for concrete beams with varying cross-sections. Steel formwork is versatile and can be easily adjusted and modified to accommodate different shapes and sizes of concrete beams. This flexibility makes it an ideal choice for construction projects that require varying cross-sections in the concrete beams.

- Q: What are the different accessories required for steel formwork maintenance?

- Some of the different accessories required for steel formwork maintenance include formwork release agents, cleaning solutions, wire brushes, repair materials such as epoxy or cementitious grout, lubricants for hinges and pins, and protective coatings for corrosion prevention. Additionally, tools such as hammers, wrenches, and pliers may be needed for minor repairs or adjustments.

Send your message to us

Protection Platform for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords