Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

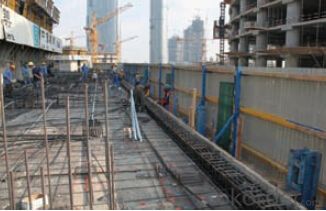

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: How does steel formwork contribute to the sustainability of a project?

- Steel formwork contributes to the sustainability of a project in several ways. Firstly, steel is a highly durable material, capable of withstanding the rigors of construction and repeated use over time. This means that steel formwork can be reused multiple times, reducing the need for new formwork to be manufactured for each project. By minimizing the demand for new materials, steel formwork helps to conserve natural resources and reduce the environmental impact associated with the extraction, production, and transportation of construction materials. Additionally, steel formwork offers excellent dimensional stability, which ensures precision and accuracy in construction. This reduces the likelihood of errors and rework, leading to a more efficient use of resources, including time, labor, and materials. The use of steel formwork also results in smooth and high-quality finishes, reducing the need for additional surface treatments or finishes, which can be resource-intensive and contribute to waste generation. Furthermore, steel formwork can be easily dismantled and recycled at the end of its lifespan. The steel can be melted down and repurposed for other construction projects, diverting waste from landfills and reducing the demand for virgin steel production. This closed-loop approach to material use aligns with the principles of a circular economy and helps to reduce the carbon footprint of the construction industry. Lastly, steel formwork provides enhanced safety on construction sites. Its strength and stability minimize the risk of accidents and structural failures, protecting workers and the surrounding environment. By promoting a safe working environment, steel formwork contributes to the overall sustainability of a project by preventing injuries, reducing medical costs, and minimizing the negative social and economic impacts associated with accidents. In summary, steel formwork contributes to the sustainability of a project through its durability, reusability, dimensional stability, recyclability, and safety benefits. By reducing the need for new materials, minimizing waste generation, and enhancing construction efficiency, steel formwork helps to conserve resources, mitigate environmental impacts, and promote a more sustainable construction industry.

- Q: What are some of the components of the combined steel template, what role?

- First, the material requirements1, the length of the plane template specification: 450, 600, 750, 900, 1200, 1500; width:: 100, 150, 200, 250, 300mm, rib height are 55mm, code2, setting steel angle mould internal corner template specification: width 150mm * 150mm, 100mm * 150mm; length of 450, 600, 900, 1200, 1500mm; rib height of 55mm, named E; Yang angle template specification: width 100mm * 100mm, 50mm * 50mm. The length and the rib height with the internal corner template, code named Y; connecting angle template specification: width 50mm * 50mm, and the length of rib height template likewise yam Kok, named J.

- Q: What are the different types of formwork clamps used in steel formwork?

- There are several types of formwork clamps that are commonly used in steel formwork construction. These clamps are designed to securely hold the formwork panels together, ensuring stability and accuracy during the concrete pouring process. 1. Wedge Clamps: Wedge clamps are one of the most commonly used formwork clamps. These clamps consist of a wedge-shaped piece that is inserted into a slot on the formwork panel. As the wedge is driven further into the slot, it creates a tight and secure connection between the panels. 2. Rapid Clamps: Rapid clamps are a type of formwork clamp that allows for quick and easy installation and removal. They are designed with a spring-loaded mechanism that allows the clamp to be easily tightened or loosened with minimal effort. 3. Turnbuckle Clamps: Turnbuckle clamps are adjustable clamps that are used to provide additional tension and support to the formwork panels. These clamps consist of a threaded rod with a turnbuckle mechanism that can be tightened or loosened to adjust the tension on the formwork. 4. Pipe Clamps: Pipe clamps are a type of formwork clamp that uses pipes or tubes to connect and secure the formwork panels. These clamps typically consist of a U-shaped bracket that is attached to the formwork panel and a pipe or tube that is inserted into the bracket to hold the panels together. 5. Panel Clamps: Panel clamps are specifically designed to hold large formwork panels together. These clamps typically consist of a large, heavy-duty clamp that can be tightened or loosened to securely hold the panels in place. Each type of formwork clamp has its own unique features and advantages, and the choice of clamp will depend on factors such as the size and weight of the formwork panels, the desired level of stability, and the specific requirements of the construction project.

- Q: What are the different components of a steel formwork system?

- A steel formwork system typically consists of several components that work together to create a sturdy and reliable structure for concrete casting. These components include: 1. Panels: Steel formwork panels are the main part of the system and are usually made of high-quality steel sheets. These panels are designed to provide a smooth and even surface for concrete pouring. They come in different sizes and shapes to accommodate various types of construction projects. 2. Connectors: Connectors are used to join the panels together and ensure they remain in place during concrete pouring. These connectors can be in the form of clamps, bolts, or pins, and they help to create a tight and secure fit between the panels. 3. Props: Props or vertical supports are used to provide additional support and stability to the formwork system. They are designed to withstand the weight of the concrete and prevent the formwork from collapsing. Props can be adjustable in height, allowing for flexibility in formwork design. 4. Beams: Steel beams are used to support the weight of the formwork system and transfer it to the ground. These beams are typically placed horizontally and provide a strong framework for the panels and other components to rest on. They are often adjustable in length to accommodate different project requirements. 5. Bracing: Bracing elements, such as diagonal struts and cross braces, are used to reinforce the formwork system and prevent it from buckling or deforming under the pressure of the concrete. These bracing components are strategically placed to distribute the load evenly and enhance the overall stability of the system. 6. Accessories: There are various accessories that can be used to enhance the functionality and efficiency of a steel formwork system. These include corner pieces, wedge bolts, release agents, and chamfer strips. These accessories help to improve the overall performance of the formwork system and ensure smooth and accurate concrete casting. Overall, a steel formwork system is a comprehensive solution for creating strong and durable concrete structures. Its different components work together to provide stability, flexibility, and ease of use, making it a preferred choice in various construction projects.

- Q: Is steel formwork resistant to corrosion?

- Yes, steel formwork is generally resistant to corrosion. Steel, particularly stainless steel, is known for its high resistance to corrosion, making it a suitable choice for construction applications. However, it is important to note that the extent of corrosion resistance can depend on factors such as the grade of steel used, the environment in which the formwork is used, and the presence of any additional protective coatings. Regular maintenance and proper care can also help prolong the lifespan and corrosion resistance of steel formwork.

- Q: Is steel formwork more durable than other types of formwork?

- Yes, steel formwork is generally considered more durable than other types of formwork. Steel has high strength and can withstand heavy loads, making it ideal for construction projects that require repetitive use and long-term durability. Additionally, steel formwork is resistant to warping, shrinking, and moisture damage, which further enhances its durability compared to other formwork materials such as wood or aluminum.

- Q: Can steel formwork be used for retaining walls?

- Yes, steel formwork can be used for retaining walls. Steel formwork is a popular choice for retaining walls due to its durability and strength. It provides excellent support and stability to the concrete during the construction process. Steel formwork is capable of withstanding the pressure exerted by the concrete and the soil behind the retaining wall, ensuring that the structure remains intact. Additionally, steel formwork offers flexibility in terms of shape and size, allowing for the construction of various retaining wall designs. Overall, steel formwork is a reliable and efficient choice for retaining walls, offering long-lasting performance and ease of construction.

- Q: What is steel formwork?

- Steel formwork is a type of temporary mold or structure that is used in construction to shape and support concrete until it sets and hardens. It is made of steel sheets or plates that are welded together to create a framework. This framework is then used to hold the concrete in place while it is poured and compacted. Steel formwork is known for its durability, strength, and ability to withstand the pressure exerted by wet concrete. It is commonly used in large-scale construction projects, such as high-rise buildings, bridges, and tunnels, where the concrete needs to be shaped into complex and precise forms. Steel formwork can be easily assembled and disassembled, making it reusable and cost-effective. It also provides a smooth and uniform finish to the concrete surface, resulting in a high-quality end product. Overall, steel formwork is an essential tool in modern construction that helps in the efficient and effective construction of concrete structures.

- Q: Is steel formwork suitable for projects with high concrete strength requirements?

- Indeed, steel formwork proves to be a fitting choice for endeavors demanding robust concrete potency. Renowned for its exceptional fortitude and endurance, steel formwork emerges as an ideal candidate for projects necessitating elevated concrete strength. It deftly endures the concrete's pressure and weight, assuring steadfastness and structural integrity throughout the pouring and curing phases. Furthermore, steel formwork grants the concrete a seamless and uniform surface, crucial in attaining superior strength and excellence in the ultimate outcome. Moreover, the reusability of steel formwork renders it a cost-efficient alternative for ventures requiring substantial concrete strength.

- Q: How does steel formwork affect the overall aesthetics of a construction project?

- Steel formwork can have a significant impact on the overall aesthetics of a construction project. Unlike traditional timber formwork, steel formwork offers a sleek and modern appearance that can enhance the visual appeal of a structure. The clean lines and smooth surfaces created by steel formwork can give a building a more polished and sophisticated look. Additionally, steel formwork allows for greater precision and accuracy in shaping concrete, resulting in a more uniform and seamless finish. This can be particularly important in architectural designs that require intricate or complex shapes. The use of steel formwork ensures that the concrete is poured exactly as intended, leading to a more visually appealing end result. Furthermore, steel formwork is highly durable and resistant to wear and tear. Unlike timber formwork, it does not warp or deform over time, maintaining its structural integrity and aesthetic appeal for a longer period. This durability can contribute to the longevity and overall quality of a construction project, making it a more attractive investment for both owners and potential buyers. Another advantage of steel formwork is its adaptability. Steel can be easily molded and shaped into various sizes and configurations, allowing for greater design flexibility. This versatility enables architects and designers to create unique and eye-catching structures that can stand out from the crowd. In summary, the use of steel formwork in a construction project can have a positive impact on its overall aesthetics. Its sleek appearance, precise shaping capabilities, durability, and design flexibility all contribute to a visually appealing end result. Steel formwork can enhance the architectural design, create a more polished finish, and increase the longevity and value of the structure.

Send your message to us

Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords