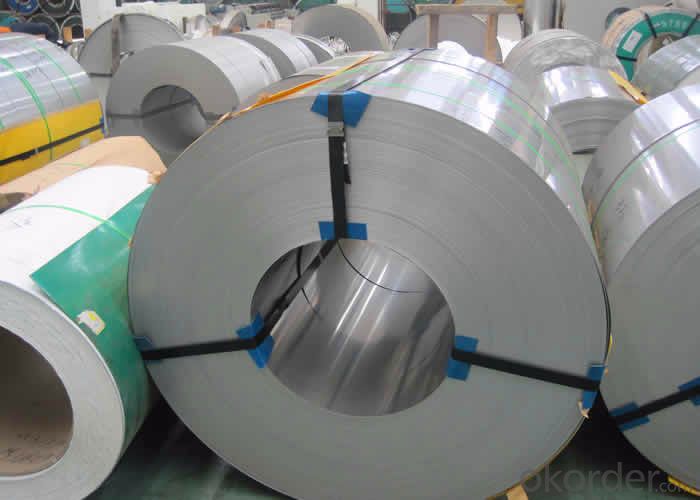

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1,2b 201 stainless steel coil thickness0.2~1.5mm

2.Ensure you quality timely delivery

3.2B finish

4.Tolerance 0.01mm

JMSS cold rolled 2b 304 stainless steel coil

Item Details:

1, 2b 304 stainless steel coil with thickness 0.2~1.5mm

2, Finishing: 2B

3, Width: 15~500mm

4. Tolerance: -0.01mm~0.01mm

Our advantage

1, High quality: Using lastest automated control equipment to ensure 2b 201 stainless steel coil quality, such as AGC system.

2, Best Price: With most automated equipments to cost down.

3, Fast delivery: Since your order placed, ETD will be only 10 days.

4, Best Sevice: We do believe your encouragement is the best support for us.

Shipping information:

1, Payment terms: T/T 30% for depsoit, Balance against the copy of B/L; or L/C at sight

2, ETD: 10-15 days after the receipt of the deposit

3, Ship terms: FOB Ningbo

4, Minimum quantity: 5 tons

Contact and Feedback:

If you are interested in any of 2b 201 stainless steel coil or any question, please feel free to contact us. We will reply you within 24H.

Our Main products:

We are professional manufacturer of 201, 202, 304, 304J1 an 316L stainless steel coil. With 2B finishing, width 15 to 600mm thickness 0.2mm to 1.5mm or width 600mm to 1220mm thickness 0.3mm to 1.5mm.

- Q: How is stainless steel strip manufactured?

- Stainless steel strip is manufactured through a process called cold rolling, where stainless steel sheets are compressed between a series of rollers to reduce their thickness. The sheets are then annealed to improve their ductility and further rolled until the desired thickness and finish is achieved. Finally, the stainless steel strip is cut into the required widths and lengths.

- Q: How do you prevent intergranular corrosion of stainless steel strips?

- To prevent intergranular corrosion of stainless steel strips, several measures can be taken: 1. Use low carbon grades: Intergranular corrosion occurs due to the precipitation of chromium carbides at grain boundaries when stainless steel is exposed to high temperatures for an extended period. By using low carbon grades, such as Type 304L or Type 316L, the carbon content is minimized, reducing the formation of carbides and thus preventing intergranular corrosion. 2. Heat treatment: After welding or other high-temperature processes, stainless steel strips should be properly heat-treated to restore the corrosion resistance. This process, known as solution annealing or sensitization treatment, involves heating the material to a specific temperature range and then rapidly cooling it to dissolve the carbides and prevent their precipitation at grain boundaries. 3. Pickling and passivation: Pickling involves the use of an acid solution to remove any impurities or contaminants from the stainless steel surface, while passivation creates a protective oxide layer on the surface to enhance corrosion resistance. Regular pickling and passivation treatments can help prevent intergranular corrosion by removing any potential corrosion sites and improving the overall surface condition. 4. Avoid exposure to high temperatures: Stainless steel strips should be protected from prolonged exposure to high temperatures, as this can lead to sensitization and subsequent intergranular corrosion. If unavoidable, the use of thermal barriers, such as insulation or coatings, can help minimize the direct contact between the stainless steel and the elevated temperatures. 5. Use corrosion inhibitors: Applying corrosion inhibitors, such as specialized coatings or inhibitors in the working environment, can provide an additional layer of protection against intergranular corrosion. These inhibitors work by forming a protective film on the stainless steel surface, preventing the attack of corrosive agents and reducing the risk of intergranular corrosion. Overall, preventing intergranular corrosion of stainless steel strips involves a combination of material selection, proper heat treatment, surface treatment, and protection measures. By implementing these preventive measures, the risk of intergranular corrosion can be significantly reduced, ensuring the long-term durability and performance of stainless steel strips.

- Q: Are 111 stainless steel strips suitable for food processing equipment?

- Food processing equipment can benefit from the use of 111 stainless steel strips, as they possess excellent corrosion resistance, strength, and hygienic properties. The widely utilized stainless steel material is known for its versatility in the food industry. Grade 304 stainless steel, also referred to as the 111 stainless steel grade, is particularly popular in food processing equipment due to its outstanding resistance to corrosion caused by acids, alkalis, and other chemicals commonly found in food processing environments. Another advantage is that Grade 304 stainless steel is non-porous, making it effortless to maintain high levels of hygiene by ensuring easy cleaning. Therefore, opting for 111 stainless steel strips would be a suitable decision for food processing equipment.

- Q: What are the common flatness tolerances for stainless steel strips?

- The common flatness tolerances for stainless steel strips vary depending on the specific grade and thickness of the material. However, in general, the industry standard flatness tolerances for stainless steel strips are typically specified as a maximum deviation from a perfectly flat surface. For precision or high-quality stainless steel strips, the common flatness tolerance is often expressed in terms of "bow" or "camber" measurements. Bow refers to the deviation of the strip from a straight line while camber refers to the deviation from a flat surface. The typical flatness tolerance for bow or camber in stainless steel strips can range from 0.5mm to 2mm per meter of length. On the other hand, for standard or commercial-grade stainless steel strips, the flatness tolerances may be slightly higher. It can range from 1mm to 4mm per meter of length. It is important to note that these tolerances are just general guidelines and can vary depending on the specific requirements of a project or application. Additionally, manufacturers and suppliers may have their own specific flatness tolerances based on their capabilities and equipment. It is always recommended to consult the manufacturer or supplier for the exact flatness tolerances for a particular stainless steel strip.

- Q: What are the different thicknesses available for stainless steel strips?

- Stainless steel strips are available in various thicknesses to suit different applications and requirements. Typically, the thickness options for stainless steel strips range from 0.0015 inches (0.0381 mm) to 0.125 inches (3.175 mm) or even thicker, depending on the specific project needs. These thicknesses are commonly measured in gauge, with 22 gauge (0.030 inches) and 16 gauge (0.0625 inches) being the most prevalent. Nonetheless, it should be noted that stainless steel strips can be tailored to meet specific thickness requirements if necessary. The choice of thickness will be influenced by factors such as the intended usage of the strips, the desired level of durability and strength, and any applicable industry standards or regulations that must be adhered to.

- Q: Are 111 stainless steel strips resistant to pitting and crevice corrosion?

- Yes, 111 stainless steel strips are resistant to pitting and crevice corrosion.

- Q: What are the factors affecting the strength of 111 stainless steel strips?

- The strength of 111 stainless steel strips can be influenced by various factors. These factors include the composition of the steel, the heat treatment process, the amount of cold working applied, the grain size, the surface finish, the environmental conditions, the manufacturing process, and the design considerations. Regarding composition, the strength of the steel can be greatly impacted by the chemical composition, particularly the levels of elements such as nickel, chromium, and molybdenum. Higher amounts of these elements generally result in increased strength. The heat treatment process used during manufacturing is another significant factor. Annealing, quenching, and tempering can alter the microstructure of the steel, leading to changes in strength. The amount of cold working or deformation applied to the steel during processing is also important. Cold working can enhance strength by introducing dislocations, but excessive cold working can cause brittleness. The grain size of the steel is another influential factor. Smaller grain sizes tend to result in higher strength due to increased grain boundaries, which hinder dislocation movement. The surface finish of the steel can affect its strength, particularly in terms of fatigue resistance. Smooth and polished surfaces tend to improve the material's fatigue strength. The environment in which the steel is used can impact its strength as well. Factors such as temperature, humidity, and exposure to corrosive substances can lead to degradation and reduced strength over time. The specific manufacturing process employed can also influence the strength of the steel. Variables such as rolling techniques, annealing processes, and cold reduction methods can all have an impact. The design of the steel, including factors like thickness, width, and the presence of surface defects or notches, can also affect strength. Proper design considerations should be made to ensure optimal strength and performance. It is important to note that these factors are interconnected, and changes in one factor can influence the others. Manufacturers and engineers must carefully consider all these factors to achieve the desired strength and performance of 111 stainless steel strips.

- Q: Stainless steel narrow band, what are the spare rolls and side bands?

- Narrowband: General slitting machine, can only be divided into 12 ~ 15 mm width, and then down, it is not accurate, and therefore narrower band, you must use a special separator, so the price of narrowband will be higher.

- Q: Can stainless steel strips be used in the brewing industry?

- The brewing industry can indeed utilize stainless steel strips. Stainless steel is widely chosen in the brewing industry because of its durability, resistance to corrosion, and ease of cleaning. Within breweries, stainless steel strips are commonly employed for constructing brewing vessels, fermentation tanks, piping systems, and heat exchangers. By utilizing stainless steel strips, the brewing equipment and components become resistant to the corrosive and acidic nature of brewing ingredients, as well as capable of withstanding high temperatures and pressures. Furthermore, stainless steel is a sanitary material, making it suitable for the food and beverage industry. In summary, stainless steel strips prove to be an excellent option for the brewing industry, presenting a dependable and long-lasting solution for a variety of brewing applications.

- Q: Can stainless steel strips be used in high-temperature applications?

- Certainly! High-temperature applications can indeed utilize stainless steel strips. Renowned for its impressive heat resistance, stainless steel is capable of enduring elevated temperatures while maintaining both its strength and structural integrity. With a high melting point and minimal thermal expansion, stainless steel proves to be an excellent choice for environments characterized by heightened temperatures. Moreover, its resistance to oxidation and corrosion further enhances its aptness for high-temperature applications. Industries such as aerospace, automotive, chemical, and power generation frequently employ stainless steel strips in order to withstand extreme temperatures and challenging conditions.

Send your message to us

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords