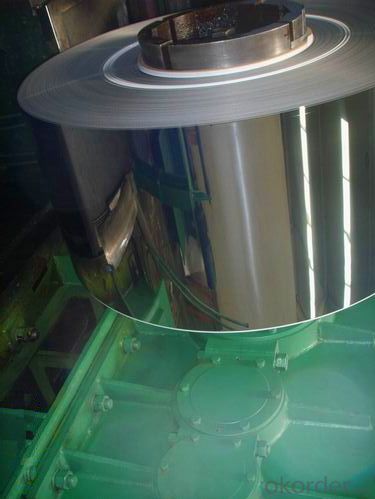

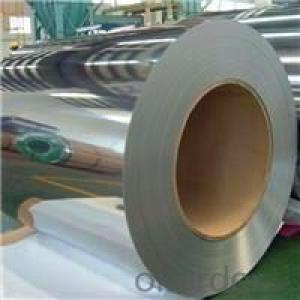

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 2B | Standard: | JIS,AISI,GB | Length: | as customers' requested |

| Thickness: | 2.5mm;3.0mm;4.0mm or as required | Width: | 485mm,510mm,600mm or as required | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CMAX | Model Number: | 201 | Type: | Coil |

| Application: | Decoration,Boiler Plate,Chemical Industry,Container plate,ship | Certification: | SGS,ISO | Color: | natural color |

| Available Finish: | 2B/BA/8K/No.4/SB/HL | Edge: | slit edge and mill edge | Features: | accurate dimensions |

| Manufacture technology: | cold drawn,pickling, hot rolled and cold rolled | DDQ: | slivery bright surface | Quality: | high quality Hot rolled stainless steel coil 201 |

| Stock: | Always in stock | Item: | Hot rolled stainless steel coil 201 |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as customer's requirement Hot rolled stainless steel coil 201 |

| Delivery Detail: | In 15 days |

Specifications

Hot rolled stainless steel coil 201

Width:485mm,510mm,600mm or as required

Thickness: 2.5mm;3.0mm;4.0mm or as required

Product Description

Stainless steel coil; stainless steel cold rolled coil;201 stainless steel coil; stainless steel coil

A. stainless steel coil

B. with competitive prices and fast delivery

C. High quality

Tisco 201 stainless steel coil

Thickness: 2.5mm;3.0mm;4.0mm or as required

Width: 485mm,510mm,600mm or as required

Length: As required

Material:201

201 stainless steel coil chemical composition

201 stainless steel coil | ||||||||

Grade | Chemical composition | |||||||

C | Si | Mn | P | S | Ni | N | Cr | |

% | % | % | % | % | % | % | % | |

201 | ≤0.15 | ≤0.75 | 5.5~7.50 | ≤0.060 | ≤0.030 | 3.50~5.50 | ≤0.25 | 16.00-18.00 |

201 stainless steel coil physical property

Physical Property | ||||

density | Strength of extension | yield strength | elongation | modulus of elasticity |

g/cm³ | psi | psi | % | psi |

7.93 | 100000-180000 | 50000-15000 | 55-60 | 29000000 |

Item | 201 stainless steel coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,430 |

Surface | NO.1,2b,4K,8k,HL,mirror finish |

Thickness | 0.3-100mm |

Width | 500-2000mm |

Price term | FOB,CFR,CIF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

- Q: Can 111 stainless steel strips be used in the pharmaceutical industry?

- Yes, 111 stainless steel strips can be used in the pharmaceutical industry. Stainless steel is known for its corrosion resistance, durability, and hygienic properties, which makes it suitable for various applications in the pharmaceutical sector. The 111 stainless steel grade typically refers to AISI 304 stainless steel, which is one of the most commonly used stainless steel grades in pharmaceutical equipment and infrastructure. It is resistant to many chemicals and can withstand high temperatures, making it ideal for pharmaceutical processing equipment, such as tanks, vessels, and pipes. Additionally, stainless steel strips can be used for packaging purposes, ensuring the integrity and safety of pharmaceutical products. Overall, 111 stainless steel strips are a reliable choice for the pharmaceutical industry due to their excellent properties and compatibility with the industry's stringent requirements.

- Q: How do you prevent microbiologically influenced corrosion of stainless steel strips?

- Microbiologically influenced corrosion (MIC) poses a common problem across various industries, including the corrosion of stainless steel strips. To maintain the integrity of these strips and prevent MIC, it is possible to implement several preventive measures: 1. Opt for Resistant Stainless Steel: Select stainless steel grades that exhibit resistance to MIC, such as 316L or higher-grade alloys. These alloys contain higher levels of molybdenum, which enhances their ability to resist microbiological corrosion. 2. Ensure a Smooth Surface Finish: Guarantee that the stainless steel strips possess a polished and smooth surface finish. Rough surfaces provide crevices and pits that facilitate the thriving of microorganisms and the initiation of corrosion. Consistent cleaning and polishing help maintain surface smoothness. 3. Regular Cleaning and Maintenance: Consistently clean and sanitize the stainless steel strips to eliminate any biofilms or organic matter that may harbor microorganisms. Employ industry-approved cleaning agents and techniques to eradicate potential sources of microbial growth. 4. Employ Biocide Treatments: Apply suitable biocides or antimicrobial coatings to the stainless steel strips. These treatments can impede the growth of microorganisms and prevent corrosion initiation. However, it is crucial to choose biocides that are compatible with stainless steel to avert any adverse reactions. 5. Control the Environment: Maintain appropriate environmental conditions by regulating temperature, humidity, and the presence of corrosive chemicals. Microorganisms thrive in specific conditions, and by managing these factors, microbial growth can be minimized. 6. Implement Cathodic Protection: Introduce cathodic protection techniques, such as impressed current or sacrificial anode systems, to provide an additional layer of corrosion protection. These techniques aid in mitigating the effects of MIC on stainless steel strips. 7. Regularly Inspect and Monitor: Conduct regular inspections to identify any indications of corrosion or microbial growth on stainless steel strips. Establish a monitoring program that encompasses visual inspections, microbiological testing, and corrosion rate measurements to detect early signs of MIC and take appropriate measures. By implementing these preventive measures, the likelihood of microbiologically influenced corrosion on stainless steel strips can be significantly reduced, thereby ensuring their durability and performance.

- Q: Can stainless steel strips be used in the production of chemical tanks?

- Indeed, the utilization of stainless steel strips is feasible for manufacturing chemical tanks. Renowned for its remarkable resistance to corrosion, stainless steel proves to be an appropriate substance for containing and conveying diverse chemicals. The incorporation of stainless steel strips in the fabrication of chemical tanks guarantees robustness, longevity, and immunity to chemical reactions that may transpire within said tanks. Moreover, the strength and capacity of stainless steel to endure elevated temperatures establish it as a trustworthy option for securely storing and transporting chemicals.

- Q: Can 111 stainless steel strips be polished to a mirror-like finish?

- It is indeed possible to achieve a mirror-like finish on 111 stainless steel strips. However, the key factors that determine this outcome are the quality of the stainless steel strips and the polishing method employed. Stainless steel possesses inherent qualities such as a smooth surface and resistance to corrosion, which enable it to be polished to a high shine. Nevertheless, attaining a mirror-like finish necessitates a meticulous polishing process that involves several stages of abrasive materials and polishing compounds. By employing the appropriate equipment and technique, it becomes feasible to polish 111 stainless steel strips to a mirror-like finish, resulting in an exceptionally reflective and aesthetically pleasing surface.

- Q: Can stainless steel strips be used for chemical reactors?

- Yes, stainless steel strips can be used for chemical reactors. Stainless steel is highly resistant to corrosion and is known for its durability, making it suitable for handling various chemicals and withstanding high temperatures and pressures typically found in chemical reactor applications.

- Q: What are the dimensions of stainless steel strips?

- The dimensions of stainless steel strips can vary depending on the specific needs and requirements of the application. However, stainless steel strips are commonly available in various thicknesses ranging from 0.1mm to 6mm and widths ranging from 10mm to 2000mm. The length of stainless steel strips can also vary, but it is typically available in coils or rolls of standard lengths, such as 1000mm or 2000mm. Additionally, stainless steel strips can be custom-cut to specific dimensions to suit individual project requirements.

- Q: How do stainless steel strips compare to other materials?

- When comparing stainless steel strips to other materials, they stand out for several reasons. Firstly, stainless steel is renowned for its exceptional resistance to corrosion. This characteristic makes it the perfect choice for applications that involve exposure to moisture, chemicals, or harsh environments. Unlike other materials, stainless steel does not easily rust or stain, ensuring durability and longevity. Secondly, stainless steel strips exhibit outstanding strength and toughness. They possess a high tensile strength, enabling them to withstand heavy loads and resist deformation under stress. This quality makes stainless steel strips suitable for applications that require structural integrity and reliability. Another notable advantage of stainless steel strips lies in their aesthetic appeal. Stainless steel has a sleek and modern appearance that can enhance the visual appeal of any project or product. It is commonly utilized in architecture and interior design due to its clean and contemporary look. Moreover, stainless steel strips offer exceptional versatility. They can be easily formed, welded, and fabricated into various shapes and sizes to meet specific requirements. This flexibility allows stainless steel strips to be utilized across a wide range of industries, including construction, automotive, aerospace, and manufacturing. Lastly, stainless steel is a sustainable and environmentally friendly material. It is 100% recyclable, making it an excellent choice for projects with a focus on sustainability. Additionally, stainless steel has a long lifespan, reducing the need for frequent replacements and minimizing waste. In conclusion, stainless steel strips excel in terms of corrosion resistance, strength, aesthetic appeal, versatility, and sustainability when compared to other materials. These characteristics make stainless steel a top-notch choice for numerous applications in various industries.

- Q: Can stainless steel strips be used in the pharmaceutical machinery?

- Yes, stainless steel strips can be used in pharmaceutical machinery. Stainless steel is preferred in the pharmaceutical industry due to its corrosion resistance, easy cleaning capabilities, and ability to withstand high temperatures and pressures. It is commonly used in pharmaceutical equipment such as conveyors, mixers, tanks, and packaging machines to ensure hygienic and efficient operations.

- Q: What are the standard coil sizes for stainless steel strips?

- The standard coil sizes for stainless steel strips typically range from 0.25 inches to 12 inches in width and 0.020 inches to 0.125 inches in thickness. However, these sizes can vary depending on the specific manufacturer and customer requirements.

- Q: Are stainless steel strips suitable for food processing?

- Yes, stainless steel strips are highly suitable for food processing. Stainless steel is widely used in the food industry due to its exceptional properties such as corrosion resistance, durability, and ease of cleaning. It is a non-reactive material, meaning it does not release any harmful substances or alter the taste of the food being processed. Stainless steel also has a smooth surface that prevents the accumulation of bacteria, making it hygienic and safe for food processing. Additionally, stainless steel strips can be easily fabricated into various shapes and sizes, making them versatile for different food processing applications such as cutting, slicing, and forming. Overall, stainless steel strips are an excellent choice for food processing due to their suitability, safety, and reliability.

Send your message to us

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords