Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil Specification:

Steel strips coils galvanized

Material: Q195, Q215, Q235, Q345B, SGCC, DX51D+Z

Thickness:0.75-4.5mm

Width:32-750mm

Zinc coating: 60-550g/m2

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil Description:

Galvanized steel coil are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 180 grams per square metre.

Main Feature of Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil:

Hot-dip galvanized steel coils are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C. The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product. To store for a longer period, the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.

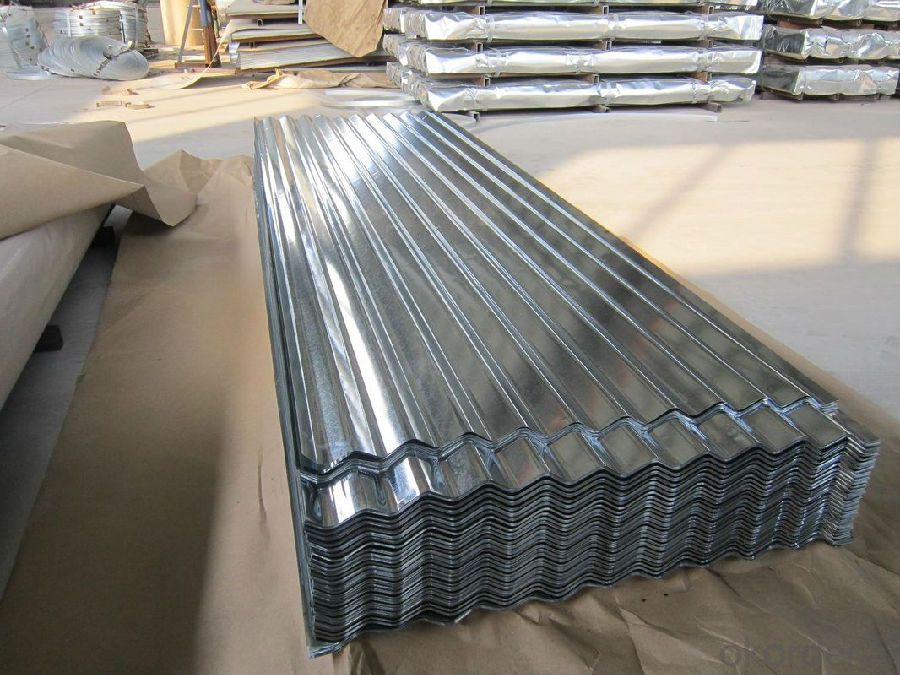

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil Images: FAQ:

FAQ:

Q: Are you manufacturer of trading company?

A: Yes.

- Q:Are steel strips suitable for making electrical transformers?

- Yes, steel strips are suitable for making electrical transformers. Steel strips are commonly used as the core material in transformers due to their magnetic properties and ability to efficiently conduct and distribute electrical energy.

- Q:How are steel strips used in the production of metal furniture hardware?

- Steel strips are commonly used in the production of metal furniture hardware due to their versatility and strength. These strips are typically made by rolling steel sheets through a series of rollers to achieve the desired thickness and shape. Once the steel strips are obtained, they can be further processed to create various components of metal furniture hardware such as brackets, hinges, handles, and drawer slides. The strips are cut, bent, and shaped into specific forms using specialized tools and machinery. One of the primary uses of steel strips in metal furniture hardware is for reinforcement purposes. By incorporating steel strips into the design, the strength and durability of the furniture hardware are significantly increased. This is particularly important for components that bear heavy loads or require frequent movement, such as hinges and drawer slides. Another application of steel strips in metal furniture hardware is for decorative purposes. The strips can be used to add aesthetic details and enhance the overall appearance of the furniture. For instance, steel strips can be bent or twisted to create intricate designs or patterns on handles and brackets, giving the furniture a more stylish and sophisticated look. Furthermore, steel strips are often used to provide structural support to the furniture. They can be integrated into the frame or structure of the furniture to increase stability and prevent sagging or warping over time. Steel strips are known for their exceptional strength and rigidity, making them ideal for ensuring the longevity and functionality of metal furniture. In summary, steel strips play a crucial role in the production of metal furniture hardware. They are utilized for reinforcement, decoration, and structural support purposes, offering strength, durability, and aesthetic appeal to the final product.

- Q:How are steel strips processed for surface leveling?

- Steel strips can be processed for surface leveling through a variety of methods. One common technique is called roller leveling, which involves passing the steel strip through a series of rollers under high pressure. These rollers apply force to the strip, gradually bending it in the opposite direction of the surface irregularities, effectively leveling the surface. Roller leveling can be performed as a standalone process or incorporated into a continuous processing line, such as a rolling mill. Another method used for surface leveling is called tension leveling. In tension leveling, the steel strip is subjected to tension forces while being passed through a series of bridle rolls. These rolls are positioned at different angles to stretch and elongate the strip, reducing surface irregularities and improving flatness. Tension leveling is particularly effective in eliminating crossbow and center buckle defects in the steel strip. Additionally, some steel strips may undergo a process called temper rolling. In this method, the strip is heated and then rapidly cooled, which alters the metallurgical structure of the steel and improves its flatness. Temper rolling can also enhance the mechanical properties of the strip, such as its hardness and strength. It is worth noting that the specific process used for surface leveling may vary depending on the requirements of the steel strip and the desired end product. Different combinations of roller leveling, tension leveling, and temper rolling can be employed to achieve the desired surface quality, flatness, and dimensional accuracy of the steel strip.

- Q:How are steel strips heat-treated for specific applications?

- Steel strips are heat-treated for specific applications by subjecting them to controlled heating and cooling processes. This involves heating the steel strips to a specific temperature and holding it there for a predetermined amount of time. The strips are then rapidly cooled, or quenched, to achieve the desired hardness, strength, or other mechanical properties. The heat treatment process can also involve tempering or annealing to further refine the steel's properties. Overall, the goal is to tailor the steel strips' microstructure to meet the specific requirements of the intended application.

- Q:Can steel strips be used in the production of bicycle frames?

- Bicycle frames can be produced using steel strips, which are frequently utilized in this manufacturing process due to their strength, durability, and affordability. By shaping and welding steel strips, it becomes possible to construct the primary structure of the frame, establishing a sturdy and inflexible foundation. The employment of steel strips enables the attainment of various shapes and sizes, facilitating design flexibility and customization. Furthermore, steel frames deliver an exceptional riding experience by absorbing vibrations and providing a smooth and comfortable journey. In summary, steel strips are a perfect selection for the production of bicycle frames as they encompass a blend of strength, durability, and adaptability.

- Q:Can steel strips be used in medical applications?

- Yes, steel strips can be used in certain medical applications. They are often utilized in the manufacturing of medical instruments and surgical tools due to their strength, durability, and resistance to corrosion. However, their specific use in medical applications depends on the requirements and regulations of each specific application.

- Q:How are steel strips coated for corrosion resistance?

- Steel strips are coated for corrosion resistance through a process called galvanization. This involves applying a layer of zinc onto the surface of the steel strip. The zinc acts as a protective barrier, preventing the steel from coming into direct contact with moisture and oxygen, which are the main factors that cause corrosion. This coating process helps to extend the lifespan of the steel strip and enhance its durability against rust and other forms of corrosion.

- Q:What is the typical thermal conductivity of steel strips?

- The typical thermal conductivity of steel strips is around 15-50 W/m·K.

- Q:What are the common applications of cold-rolled steel strips?

- Cold-rolled steel strips are commonly used in various applications such as automotive components, construction materials, home appliances, electrical equipment, and industrial machinery.

- Q:What are the different types of coatings available for steel strips?

- There are several types of coatings available for steel strips, including galvanized coatings, which provide corrosion resistance through a layer of zinc; organic coatings, which provide protection through paint or polymers; metallic coatings, such as aluminum or tin, which offer additional corrosion resistance; and phosphate coatings, which enhance adhesion and improve corrosion resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords