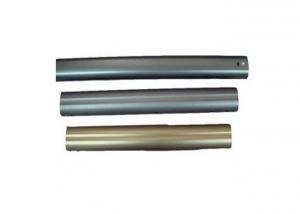

Custom Stainless Steel CNC Turning Metal Working Machining Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 3000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Stainless steel machining part

Material:Stainless steel

Process:cnc turning

Inspection:CMM and Projector

Custom machining

Stainless steel cnc turning metal working machining service

Description:

Material:Stainless steel

Surface finish:Smooth

Process:CNC turning

Package:2pcs/Bubble bag,small box and carton,also as your requirement

Advantage:

1,Fine quality

2,Precision

3,Factory direct price

4,Professional

5,On time delivery and good service

A:certification: ISO9001:2008

B.Advantages

1. we are CNC factory with almost 10 years

2. Low MOQ (100pcs is even acceptable in some special conditions)

3. Short lead time (7-30days according to order qty)

4. Customized size and spec /OEM available

- Q: Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- Standard parts can be purchased. It is better to bring the old parts with them or to provide the corresponding machine tools

- Q: How to solve tooth strain of involute spline broach?

- Sharpening the front corner of the broach requires a re opening of the backlash if it is a new cutter

- Q: Pull the rifling when rotating or broach tube rotation or both rotation??

- The pipe is fixed and the cutter head can be taken into consideration with the percussion drill at the top of the drill bit, not knowing what exactly. Only know that grinding, and pull a tube, do not rub, do not change the knife!

- Q: Hope to find a complex tool to do good enterprises, especially broaches do good, quality and Harbin first tool factory and other veteran manufacturers almost or almost no, but the price is relatively cheap, a lot of, thank you

- What I understand is that small tools such as thread cutters are good for work

- Q: Why is the tooth shape of broach oblique?

- Landlord said broach is not a saw, one is mechanical cutting forming processing, a manual cutting, how will the same? Made oblique should be angled in order to make the cutting tooth with the cutting plane, the plane like a razor blade.

- Q: Know how to draw Broaches for involute internal spline parameters

- To pull or spline spline, spline parameter is of course laane for internal spline broach;There are many factors in designing broaches, such as machine tool chucks, maximum broaching length, dimension and so on;General to broach company can do, they know how to do, need what parameters will call you to provide

- Q: Why don't carbon tools steel be used to make Broaches and gear cutters?

- Carbon tool steel is cheap and easy to forge, and its machinability is better. The main disadvantage of carbon tool steel is its poor hardenability. It needs water, brine or alkaline water quenching. The tendency of distortion and cracking is great, and its abrasion resistance and thermal strength are very low. Therefore, carbon tool steel can only be used to make some small hand tools or woodworking tools, and the accuracy requirements of the small cold is not high, simple shape, small size, light load of mold, such as used in the manufacture of small punch, scissors, die, cold die etc..Broaches and gear cutters are usually made of high speed steel

- Q: Machining center spindle broach can not reach the designated position, how to adjust?

- This is rarely the case. Did you pull the nail in the wrong way?

- Q: Is there an expert who knows the broach?!

- The rotary joint is connected and air cooling water in the water and gas into the rotary joint before all the way with the on-off valve, OTT rod which is provided with holes, similar to the valve, the locking rod cutter, shift lever, waterway connected, pneumatic on-off valve closed, the water is turned on. The coolant through the tool cooling hole nozzle. Similarly, when the rod is loose, the pull rod is pushed forward first, the air path on the pull rod is connected, and the waterway is closed, and the cone and the end face of the main shaft are blown and cleaned at this time.

- Q: CNC Lathe Feed base surface is floating, there is no good way to solve?

- I've been troubled by this problem for a long time. Just as if the needle and double processing, the depth of the top pinhole inconsistency is unable to determine the base. It's impossible for every piece of work to have a knife once,

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Custom Stainless Steel CNC Turning Metal Working Machining Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 3000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords