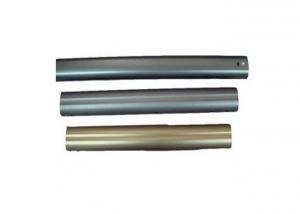

Custom Aluminium Shaft Products Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Japanese standard

2)Max. precision 0.005mm

3)Mainly export to Japan

4)aluminium shaft

5)Custom service

Material available |

|

Carbon Steel | Stainless Steel 304/314/316 etc |

Tool Steel | Aluminum 2024/5052/6061/7075 |

Brass/Copper/Bronze | POM/Acrylic/Plastic/Nylon |

|

|

Machining Service |

|

CNC machining | Lathe Machining |

Milling | Stamping and bending |

Precision Welding | Wire Cutting |

Fixtures and jigs |

|

|

|

Finish Available |

|

Polishing | Zinc/Nickel/Chrome Plating |

clear/black/blue anodizing, sandblast | black oxide |

powder coating | painting |

|

|

Features |

|

Strict QC and reliable quality | on-time delivery |

small order acceptable | custom service by drawing or sample |

|

|

Main Clients |

|

CANON, DENSO,OMRON,RICOH,MISUMI etc |

|

|

|

- Q: Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- Standard parts can be purchased. It is better to bring the old parts with them or to provide the corresponding machine tools

- Q: How to solve tooth strain of involute spline broach?

- Workpiece hardness of less than HRC30 is generally broach problem, of course, there are special. It should be cool under normal conditions. I personally do Spline Broach Design and grinding parameters, then the workpiece interested told me to give you the design drawings for reference

- Q: Why is the tooth shape of broach oblique?

- Landlord said broach is not a saw, one is mechanical cutting forming processing, a manual cutting, how will the same? Made oblique should be angled in order to make the cutting tooth with the cutting plane, the plane like a razor blade.

- Q: 5.6 small caliber gun rifling production line with much manual broach

- The general value of deep rifling line diameter of the gun bore 2%. 5.72 or 5.75 arrows that broach,

- Q: Know how to draw Broaches for involute internal spline parameters

- Are you going to pull the spline or external spline spline parameters is of course laane internal spline broach to do;There are many factors in designing broaches, such as machine tool chucks, maximum broaching length, dimension and so on;General to broach company can do, they know how to do, need what parameters will call you to provide

- Q: Why don't carbon tools steel be used to make Broaches and gear cutters?

- Carbon tool steel is cheap and easy to forge, and its machinability is better. The main disadvantage of carbon tool steel is its poor hardenability. It needs water, brine or alkaline water quenching. The tendency of distortion and cracking is great, and its abrasion resistance and thermal strength are very low. Therefore, carbon tool steel can only be used to make some small hand tools or woodworking tools, and the accuracy requirements of the small cold is not high, simple shape, small size, light load of mold, such as used in the manufacture of small punch, scissors, die, cold die etc..Broaches and gear cutters are usually made of high speed steel

- Q: Microcrystalline stone tile for broach can open it

- The microcrystal surface will collapse

- Q: Machining center spindle broach can not reach the designated position, how to adjust?

- This is rarely the case. Did you pull the nail in the wrong way?

- Q: Is there an expert who knows the broach?!

- The broaching mechanism is an automatic tensioning and automatic releasing mechanism for the main shaft of a small numerical control machine tool.principleBy pre compressing the disc spring, sufficient upward broaching force is produced. When you need to change the knife, a knife loosening signal control system, through the electromagnetic reversing valve to control the hydraulic system, hydraulic cylinder pressure oil system will pass into the upper end of the main axle on the chamber, the piston pushing broach parts move down, continue to compress the disc spring, handle downward movement, and through the tool changing manipulator with complete change knife. At the upper end of the cylinder, there are two proximity switch to detect the cylinder piston is in place; if the cylinder is not in place, then the two proximity switches will not signal the NC system will not continue to the next procedure, to ensure the safety of CNC machine tools.

- Q: CNC Lathe Feed base surface is floating, there is no good way to solve?

- I've been troubled by this problem for a long time. Just as if the needle and double processing, the depth of the top pinhole inconsistency is unable to determine the base. It's impossible for every piece of work to have a knife once,

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Custom Aluminium Shaft Products Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords