QM16200 ACCU-LOCK MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

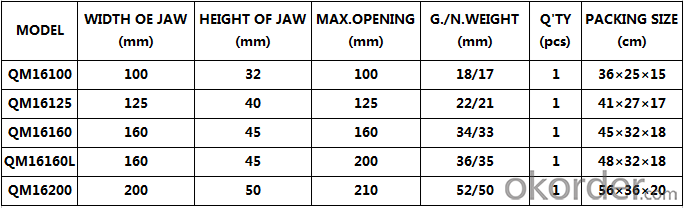

QM Series MachineVice

Performance and character:

1. It is one of main attachmentsfor milling、drillingmachine ,it is particularly suitable for the finishing of precision parts.

2. The accuracy of vice (parallelismand squareness) is 0.025mm/100mm.

3. The special segment in themovable jaw forces the vertical pressure downward when the horizontal pressureworks, so that this jaw does not lift the work piece.

4. Four positions allow extracapacity to change opening of jaw.

- Q: One: what is a heavy bench vice? 2: what is the characteristic of heavy bench vice? What's the performance? What is it for?

- Its structure consists of forceps, base, guide nut, screw and tongs. The active tongs glide through the guide track of the guide and the fixed clamp. The screw is mounted on an active tongs, which can be rotated, but not moved, and fitted with the screw nut mounted inside the clamp. When the handle is moved to rotate the screw, it can be used to move the clamps to move the shaft of the clamps, which can be tightened or relaxed. The spring is fastened to the screw with a baffle and open pin, which is used to loosen the screw and allow the active clamp to exit in time. The clamp is fitted with steel tongs and screws fixed with screws. The work surface of the tongs is intersected, which makes it difficult to slip when the workpiece is clamped. The tongs are hardened by heat treatment and have good abrasion resistance. Fixed clamp body in a seat, and can rotate axis rotation, when transferred to the requirements of the direction, turn the clamping handle make the clamping screw tightening, can be in the clamping plate under the action of the fixed clamp body is solid and tight. There are three bolt holes in the seat to be fixed with the clamp. The specification of table vice is indicated by the width of tongs, 100mm, 125mm, 150mm etc.

- Q: How do you mill a step up the miller's vice

- I hope my answer will help you.Wash with alloy knife.In line!.Are you a professional or amateur.

- Q: Push it to the required piece of work, then lock the screw with the inner hexagon wrench to achieve a tight end. What I want to know is the design structure of it, if you have this kind of vice in your hand, you can show me a few pictures, especially the lock structure underneath it. There is a drawing change. If you know what it's called, give it a name,

- This structure used to be used mainly for the precision flat tongs used in grinding machines.

- Q: Ask questions! How large a bench vice is a carpenter?

- Make big wood, make small wood, not too big. Fine wood with lutetium.

- Q: What is mechanical vice material

- Carbon steel, a relatively poor quality, is now the most material on the market, and the price is lower

- Q: Several basic USES of bench vice

- Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q: The large aluminum plate will not deform 250 * 240 * 16

- After testing, you can stabilize the appropriate holding force ~ if you need detailed parameter data, you can trust me, or leave a

- Q: The working principle of machine vice

- Working principle analysis: machine vice is installed on machine tool workbench, used for clamping piece of workpiece, so as to make the cutting machine tool.

- Q: Can the bench vice clamp the column bar? How to clip

- The premise is that the vice must be a regular product Because now there are so many cheap vips that don't meet the standards,

- Q: What type are the tongs?

- The semiconductor plug-in unit, small robot, and so on require the micro guide ball screw pair to meet the high speed drive requirement. As mechanical products to develop in the direction of high speed, high efficiency, automation, industrial robot, CNC forging machinery, processing center, and mechanical and electrical integration of automatic machinery, such as increasing the feed drive speed

Send your message to us

QM16200 ACCU-LOCK MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches