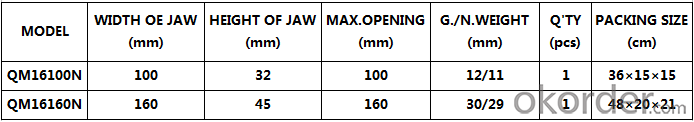

QM16100N ACCU-LOCK PRECISION MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

QMN Series Machine Vice

Performance and character:

1. It adopts the ductile cast ironwith high durability.

2. The locking structure with theangle-fixed shape can prevent the work piece fron rising during the operation.

3. Both parallelism and verticalityabout the two jaws are 0.025mm/100mm.

4. It can be used by single set orseveral sets side by side.

5. It is widely used for precision machines inthe machine center.

- Q: What does mechanical forceps mean?

- Vice. It is the vice that is attached to the table. Also known as the vise.

- Q: How to draw a vice assembly drawing

- Complete the complete picture, deepen the drawing line, draw the section line, mark the necessary dimensions, the tolerance and technical requirements, mark the parts serial number, fill in the detail form and the title bar. Thank you for your trouble! If you don't understand, please continue to ask...

- Q: How to find a positive two vice

- Then adjust the level of water level (both of which are consistent with the working table) - the magnetic watch seats are drawn on the main shaft

- Q: What is mechanical vice material

- Cast steel!The price is also higher。I hope my answer will help you。

- Q: How to fix the bench vice of the bench bench

- The bench vice has three fixed screw eyes, corresponding to the installation area of the operator, type three equal diameter screw holes, and the screw nut is fixed

- Q: Kneeling for the process of processing the machine with vice clamp

- Machine vice is a kind of machine tool accessory, usually installed in the machine tool such as milling machine, drilling machine, head planing bed, surface grinding machine and so on. The tongs are wide, low, clamped and high precision. There are many types, and the accuracy can be classified into the common type and the precision. It is used for finishing machine tools such as surface grinding machine and boring machine. The machine can be divided into the shape of the base, the fixed type without the base and the tilting type. Air, hydraulic, or eccentric CAM are also used to drive fast clamping.

- Q: What is the use of the screw on the pincers of the flat slot with two orifices

- These two should be used to locate the tiger's mouth.I hope my answer will help you.

- Q: All of the double force vice is designed with the same high design?

- It's national The model of machine vice is based on the standard of one machine, the type of machine tool accessories. 160 - the main parameter jaw width 160 mm B - type codenamed rotary machine with vice Q - the codename machine USES vice

- Q: The structure of a vice

- The screw is mounted on an active tongs, which can be rotated, but not moved, and fitted with the screw nut mounted inside the clamp. When the handle is moved to rotate the screw, it can be used to move the clamps to move the shaft of the clamps, which can be tightened or relaxed. The spring is fastened to the screw with a baffle and open pin, which is used to loosen the screw and allow the active clamp to exit in time. The clamp is fitted with steel tongs and screws fixed with screws.

- Q: How do you beat the sink hole of the pincers with two screws, with a drill or a milling cutter

- Method has a good variety of, see which one do you prefer, today the mood is good, just tell you two ways, vise has medium commonly used three, the main difference between the two screws of center distance, the most common and I guess you said is belong to medium, two hole center distance is 98 MM, the bottom of the grip to 23 MM hole center distance. (punch position must be less than 23 MM) with metric coarse threads M10, general specification M10 screw, screw diameter of 10 MM, (through hole, is bigger than him, 11, 12 MM or so can) hat head size is between 14 to 16, more than he can Lazy person programming: 8MM thick milling cutter screw, milling through hole 11, total thickness left 5 to 10MM above all milling more than 16MM head hole Most efficient programming, 11 drilling, 16 drilling to 5-10mm, thick milling cutter with two knives milling flat head holes It is not impossible to use only the drill bit, but the force area is too small and the lock screws are not very good and easy to loosen. You will regret it when you loosen the clamp, so it is absolutely not recommended to drill with a drill

Send your message to us

QM16100N ACCU-LOCK PRECISION MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches