Q12(QH)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

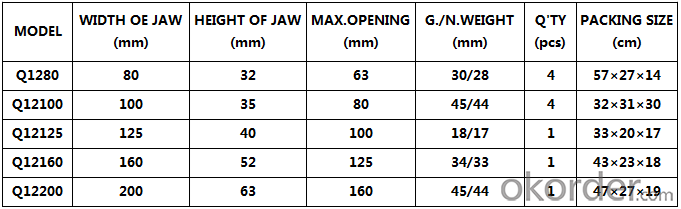

Q12(QH)series Machine Vice:

Performanceand character:

1. It adopts the high-quality castirons.

2. Both parallelism andverticality about the two jaws are 0.025mm/100mm.

3. It is widely used for themilling machine and the drilling machine to process some surface ,slots andholes.

- Q: How do you mill a step up the miller's vice

- I hope my answer will help you.Wash with alloy knife.In line!.Are you a professional or amateur.

- Q: Push it to the required piece of work, then lock the screw with the inner hexagon wrench to achieve a tight end. What I want to know is the design structure of it, if you have this kind of vice in your hand, you can show me a few pictures, especially the lock structure underneath it. There is a drawing change. If you know what it's called, give it a name,

- There are two structures, one called manual pincers, and one is called rapid pincers -- which is what you are interested in

- Q: Is the screw of a vice clamp a silk stick? How do you choose a screw with the same principle? The device requires a general assembly

- The commonly used screw is not retracted automatically, but your "self-lock" is accurate and is a term. The specific reasons are theoretical and inexplicable, and they are not explained here. Also, if there is the use of the old screw, it is best to be able to make a cheap, reasonably practical bench vice.

- Q: How to find a positive two vice

- Then adjust the level of water level (both of which are consistent with the working table) - the magnetic watch seats are drawn on the main shaft

- Q: Describe the method of attaching the piece of work to the machining center with vice clamp.

- So that's the same thing as the X-axis. And then fix it,I hope my answer will help you

- Q: Ask questions! How large a bench vice is a carpenter?

- There are conditions for a 5-inch, heavy-duty, working, cleaning tool. Remember to buy a good brand.

- Q: What is mechanical vice material

- Cast steel!The price is also higher。I hope my answer will help you。

- Q: How does the UG set the motion simulation of the bench vice

- In fact, there is a problem, the screw driver problem, hehe The question that you ask is still a few general, oneself seek some data to see, have specific problem again ask a bit better

- Q: Kneeling for the process of processing the machine with vice clamp

- Machine vice is a kind of machine tool accessory, usually installed in the machine tool such as milling machine, drilling machine, head planing bed, surface grinding machine and so on. The tongs are wide, low, clamped and high precision. There are many types, and the accuracy can be classified into the common type and the precision. It is used for finishing machine tools such as surface grinding machine and boring machine. The machine can be divided into the shape of the base, the fixed type without the base and the tilting type. Air, hydraulic, or eccentric CAM are also used to drive fast clamping.

- Q: The structure of a vice

- The screw is mounted on an active tongs, which can be rotated, but not moved, and fitted with the screw nut mounted inside the clamp. When the handle is moved to rotate the screw, it can be used to move the clamps to move the shaft of the clamps, which can be tightened or relaxed. The spring is fastened to the screw with a baffle and open pin, which is used to loosen the screw and allow the active clamp to exit in time. The clamp is fitted with steel tongs and screws fixed with screws.

Send your message to us

Q12(QH)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords