QBK125L TILTING MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

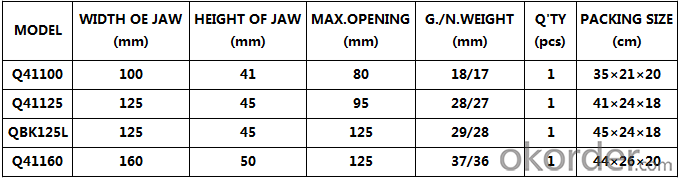

Q41(QHK) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. The vice can beadjusted and locked at random from the horizontal position to the verticalposition (0°-90°)with swiveling base being rotated 360°.

4. It can be widelyused for processing all kinds angels of surface, slots and holes.

- Q: Numerical control milling machine vice school table

- With a dial indicato.I hope my answer will help you.r

- Q: One: what is a heavy bench vice? 2: what is the characteristic of heavy bench vice? What's the performance? What is it for?

- Heavy bench vice is the width of the tongs. Common specifications from 150mm to 300mm bench vice. Bench vice, also known as vice, is a common fixture for holding the piece. The equipment is used on the workbench for the workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position. Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, chisel and components of the assembly and disassembly. Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q: Is there a god who is good at drawing mechanical drawings?

- Bench vice, also called vice, bench vice. A bench vice is a common fixture for holding a piece of work. The equipment is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position.

- Q: What are the characteristics and advantages of precision vice?

- Precision pliers structure similar to ordinary clamp structure, is a clamp body activity, fixed jaw, jaw, drive screw, nut, is only relevant parts of higher precision, cooperate more closely. There is no necessary relationship between structure principle and precision

- Q: The bench vice is used by the fitter to have which two kinds

- vise The use and type of bench vice: A and USES: a bench vice is specialized in holding the work piece, B, specification: the size of the tongs is the width of the tongs, and the usual 100mm, 125 mm and 150 mm, etc C, type: type has a fixed and rotary type

- Q: What should be noticed using a bench vice?

- The clamp shall not be made of the casing or hammer, and the workpiece shall not exceed two-thirds of the maximum travel of the tongs

- Q: Which is the strength of the hardware and wooden bench pliers?

- It is not the same as the clamping of a carpenter's tongs, which are also different from the tongs of the woodworker's tongs, which are also different, and the metalworker's tongs bite more, biting the surface of the wood surface to bite

- Q: Several basic USES of bench vice

- Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q: How to fix the bench vice of the bench bench

- The bench vice has three fixed screw eyes, corresponding to the installation area of the operator, type three equal diameter screw holes, and the screw nut is fixed

- Q: All of the double force vice is designed with the same high design?

- The standard family is different from each other, and I understand that most of them are lower than the accuracy tables above you What is alleged to be the vice of the vice that is the same as the brand only, is to tell the client to be able to be able to be able to be able to be able to use a few times

Send your message to us

QBK125L TILTING MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches