Q12(QH)200 MILLING MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

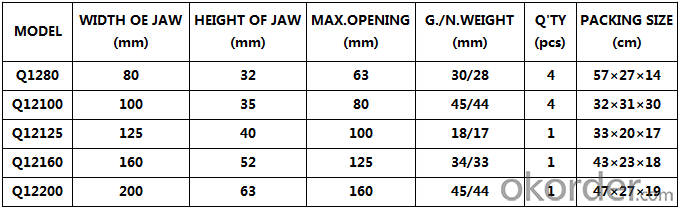

Q12(QH)series Machine Vice:

Performanceand character:

1. It adopts the high-quality castirons.

2. Both parallelism andverticality about the two jaws are 0.025mm/100mm.

3. It is widely used for themilling machine and the drilling machine to process some surface ,slots andholes.

- Q:Common production desk vice, 45 # steel make the clamp plate, how to make pattern

- I don't understand the pattern. In heat treatment, the size is smaller, and the temperature of the heat is increased by the maximum power of the furnace. The furnace controls the clearance. The heat preservation time of 30 min, oil cooling, 500 ℃ tempering, 1 h

- Q:Will the bench work on the bench vice?

- But there is also a working face plate with a rubber sheet. Generally speaking, you can meet the requirements of the job

- Q:One: what is a heavy bench vice? 2: what is the characteristic of heavy bench vice? What's the performance? What is it for?

- Its structure consists of forceps, base, guide nut, screw and tongs. The active tongs glide through the guide track of the guide and the fixed clamp. The screw is mounted on an active tongs, which can be rotated, but not moved, and fitted with the screw nut mounted inside the clamp. When the handle is moved to rotate the screw, it can be used to move the clamps to move the shaft of the clamps, which can be tightened or relaxed. The spring is fastened to the screw with a baffle and open pin, which is used to loosen the screw and allow the active clamp to exit in time. The clamp is fitted with steel tongs and screws fixed with screws. The work surface of the tongs is intersected, which makes it difficult to slip when the workpiece is clamped. The tongs are hardened by heat treatment and have good abrasion resistance. Fixed clamp body in a seat, and can rotate axis rotation, when transferred to the requirements of the direction, turn the clamping handle make the clamping screw tightening, can be in the clamping plate under the action of the fixed clamp body is solid and tight. There are three bolt holes in the seat to be fixed with the clamp. The specification of table vice is indicated by the width of tongs, 100mm, 125mm, 150mm etc.

- Q:The working principle of machine vice

- Rotation and axial movement, the screw was axial fixed so can rotate, axial movement is passed to the nut, nut with 3 screws (homemade screw), 2 pieces of 4 fixed clamp body, jaw plate moving clamping or loosening of artifacts, this is the working principle of the assembly

- Q:What is the commonly used workpiece in milling machine

- Using flat vice clamping workpiece one fixed jaw vice is the clamping workpiece positioning components, usually used to align the fixed jaw make flat vice on the machine tool positioning, namely based on fixed jaw vice in. The installation position of the worktable. Most bligh requirements use fixed jaw either vertical or horizontal, must be parallel to guide direction a, also wants in fixed jaw faces and working mesa vertical alignment method is to use 2 as shown in figure 6-4 methods for testing: the indicator. Table seat fixed on the spindle of CNC milling machine and lathe bed a proper position, makes the indicator measuring head and fixed clamp n working surface in contact. At this point, the longitudinal or transverse moving workbench, observe the indicator reading changes, which reflects the vise fixed jaw and the longitudinal or transverse feed movement of the parallel:. Along the vertical direction. If a C: Taiwan, fixed jaw and can be measured. The workbench of mesa verticality:, according to the rotary vice technical parameters, adjust the flat vise to the correct position.

- Q:Is the thread of a vice with a zigzag thread

- So don't generalize! The truth is the combination of theory.I hope my answer will help you

- Q:How to fix the bench vice of the bench bench

- There are three screw holes under the bench vice. You drill three holes in the bench with the electric drill, and then you fix it with a screw.

- Q:What type are the tongs?

- The expansion of the use of the ball screw pair using field expands unceasingly, more and more to the requirement of ball screw pair, the common specifications of the ball screw pair has far cannot satisfy the use requirement, such as aerospace field, small precision testing device, electronic instrument and semiconductor device basically need d0 nominal diameter 12 mm or less, lead Ph = 0.5 ~ 2.5 mm mini ball screw pair. Japan's NSK company has developed the world's smallest lead micro-ball screw with a diameter d0 = 4mm and the lead Ph = 0.5 mm. 15 straight screw? 1510 ball screw and so on, the manilus is pretty good

- Q:What is the difference between the heavy duty and the light, how to choose the size of the tongs, usually 8 inches or 10 inches

- In terms of weight, a lot of foreign countries use 4-inch, not very well at home

- Q:Who knows the calculation and selection of the tongs?

- According to the requirement of dustproof protection and the requirement of interplay and pre-tightening, the appropriate structure can be chosen.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q12(QH)200 MILLING MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products