Q12(QH)100 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

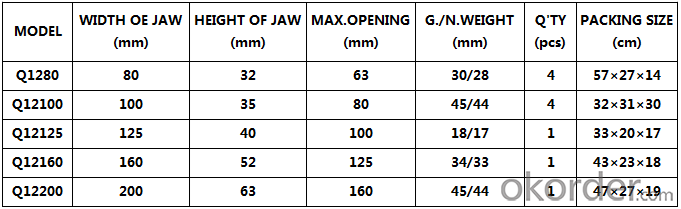

Q12(QH)series Machine Vice:

Performanceand character:

1. It adopts the high-quality castirons.

2. Both parallelism andverticality about the two jaws are 0.025mm/100mm.

3. It is widely used for themilling machine and the drilling machine to process some surface ,slots andholes.

- Q:What does mechanical forceps mean?

- The main use of the clamp clamp is to underline, sawing, filing, drilling, reaming, tapping, thread and so on.

- Q:Will the bench work on the bench vice?

- But there is also a working face plate with a rubber sheet. Generally speaking, you can meet the requirements of the job

- Q:Can the bench vice clamp the column bar? How to clip

- You can add a pair of live v-shaped pieces if you don't have them regularly If you often need to process the product of a round bar, it is recommended to remove the vice clamp and process the V groove, which will ensure the parallel and clamping of the workpiece

- Q:Is the screw of a vice clamp a silk stick? How do you choose a screw with the same principle? The device requires a general assembly

- The commonly used screw is not retracted automatically, but your "self-lock" is accurate and is a term. The specific reasons are theoretical and inexplicable, and they are not explained here. Also, if there is the use of the old screw, it is best to be able to make a cheap, reasonably practical bench vice.

- Q:How to calibrate the CNC milling machine tongs

- To find a better table or magnetic platform with a horizontal plane, use the calibration table to verify that its horizontal error is small. The existing top of the workpiece is placed on the table or on the magnetic platform, and the verticality of the semicircle and the "bottom" is measured with the school table, and the right Angle of the processing is confirmed.

- Q:How does the UG set the motion simulation of the bench vice

- In fact, there is a problem, the screw driver problem, hehe The question that you ask is still a few general, oneself seek some data to see, have specific problem again ask a bit better

- Q:How to find a positive two vice

- Use common vice for two USES, first to proofread the equal height of the vise, and to adjust the lower vise with a gasket (the can of our life can be used).

- Q:Is the thread of a vice with a zigzag thread

- Today, the vice screw of the bench in our factory was wrung, so I had to draw one, and then my own car, and I paid attention to his threads: the zigzag thread!

- Q:What type are the tongs?

- The semiconductor plug-in unit, small robot, and so on require the micro guide ball screw pair to meet the high speed drive requirement. As mechanical products to develop in the direction of high speed, high efficiency, automation, industrial robot, CNC forging machinery, processing center, and mechanical and electrical integration of automatic machinery, such as increasing the feed drive speed

- Q:Use of bench vice (simple point)

- When working with the workpiece, only the power of the hand is allowed to handle the handle, not the handle with the hammer, lest the screw, nut, or the clamp be damaged.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q12(QH)100 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products