Drilling and Tapping Center CNC Machine Model T6 with Syntec System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

High Precision

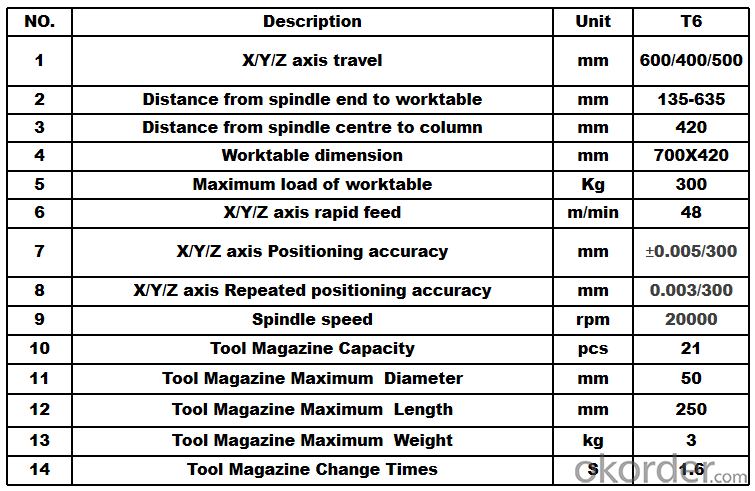

1、Spindle drive adopts high response O&R spindle, high speed up to 20,000 rpm.

2、Adopting high grade spindle ensures high reliability, long life, low noise, low vibration, high precision and other advantages of the spindle.

Strong rigidity

1、The frame is made of high-quality resin sand wear-resistant castings, strong bones, large columns, base, honeycomb structure; annealed, long-lasting and not deformed.

2、Three-axis line rail adopts on the silver steel strong precision high-speed mute guide, can withstand high-speed, high-precision cutting processing.

System option:Syntec

Technical Parameter

Package

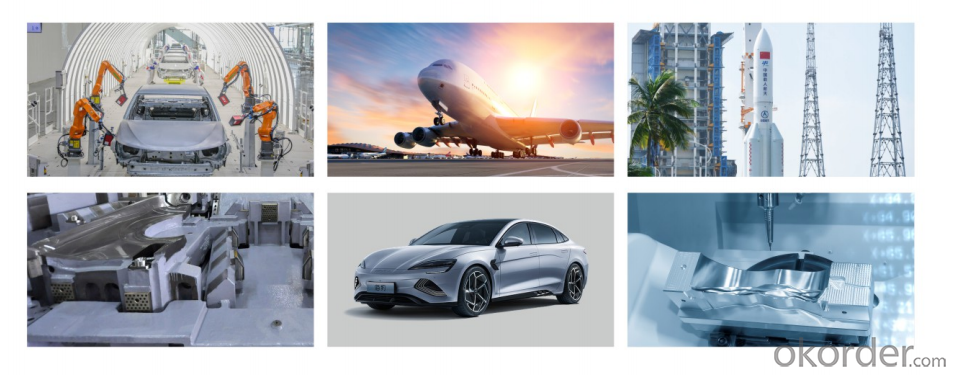

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q:Beijing precision machining center CNC machining center features what role

- System, this CNC machine tool movement and auxiliary action will be issued by the NC system command issued by the control, but the NC system instructions are by the programmer they according to the workpiece material and processing requirements, Shenzhen cnc processing there

- Q:How to set up the CNC vertical machining center

- Usually with a leveraged table to find can also be used to find the edge of the machine

- Q:What is the use of the G94 command?

- After using the G95 command, all feeds are in mm / r units, ie F100 means the spindle is rotated by 100 mm

- Q:How is the center of the processing center?

- 2. Turn to handwheel mode For example, to find the first Y to find the edge of the workpiece to the middle of the first close to the Y side of the end, such as the first close to + Y start the first hand wheel speed is adjusted to 0.1 is 10 when the fast when close to the edge

- Q:Five-sided machining center and five-axis machining center What is the difference

- Pentahedral processing center, refers to the use of composite milling head, also said that his milling head can be unloaded, fitted with composite milling head, milling head can turn angle. That is, in addition to the table outside the surface is not good processing,

- Q:Will the CNC machining center and computer gong What is the difference

- CNC machine operation and monitoring all in this CNC unit to complete, it is the brain of CNC machine tools.

- Q:Is the center of the machining center hard and rail? What is the difference between them?

- The slider has an inner circulation ball or roller, the length of the slide can be customized.

- Q:How does the machining center handle the taper hole?

- You can use the round nose knife from the D120MM from top to bottom or from before and after (according to your processing center is vertical or horizontal) and other high processing.

- Q:Processing area of the processing center

- Box type of workpieces such as the general requirements of the workpiece are more than the hole and the plane of the processing, positioning accuracy requirements, processing in the processing center when a fixture to complete the ordinary machine 60% to 95% of the process content.

- Q:How does the gantry machining center distinguish from the vertical machining center?

- Door processing center and vertical machining center are all vertical type of processing center!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drilling and Tapping Center CNC Machine Model T6 with Syntec System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches