Auto Polishing Peeling and Grinding CNC Machine JN-T8/D8/D10 for Prouding Faucets

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

We are supplying new generation CNC peeling machine which is high-precision, high-efficiency and energy-saving. It has a great improvement on the traditional grinding process.

The machine adopts gantry type body and it covers an area of only 8m², can process 8 faucets at a time, and the brass recovery rate is 100%.The casting bodies can be processed directly on this machine after the excess parts are cut off.This machine can remove all draft surfaces on products. Finish the surface up to 220-240 mesh which can replace the rough grinding process.

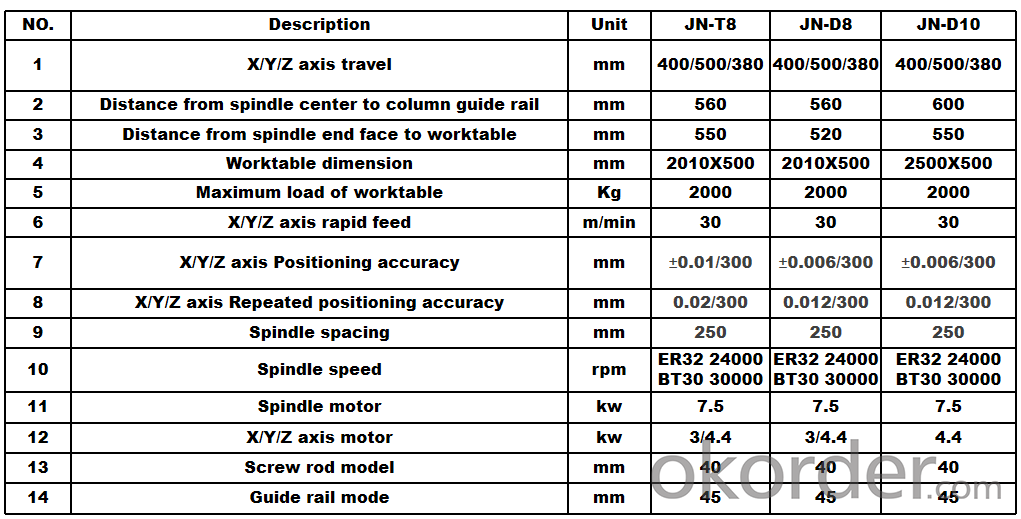

Model:JN-T8、JN-D8、JN-D10

System option:Siemens、Mitsubishi、Syntec

Technical Parameter

Package

Global Sales Market

International Partner

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: Will fanuc processing center length compensation how to use? Can you give an example to explain!

- 1 manual operation when the knife is

- Q: Machining center in the G98, G99 What does it mean?

- G98 is to return to the initial plane, G99 is to return to R points: 1. G90G00G54X0Y0; G43H1Z50M3S500; G98G81Z-20R5F100; (after processing the tool back to the Z50 position, G98 can ignore the write, the system will be the default) X50Y50;

- Q: Processing area of the processing center

- complex surface class parts complex surface can generally use the ball head cutter for coordinate processing, processing accuracy is higher, but the efficiency is low. If the workpiece exists in the processing of interference area or processing dead zone, we must consider the use of four coordinates or five coordinate linkage of the machine. Such as aircraft, car shape, impeller, propeller, all kinds of molding die.

- Q: How to process taper holes with machining centers?

- Features, speed block, high precision, eat good character The second method: is the spiral milling within the cone hole.

- Q: The difference between milling and reverse milling in cnc CNC machining center

- The direction of rotation of the contact between the milling cutter and the workpiece is the same as that of the workpiece feed direction, and vice versa.

- Q: What is the machining center?

- Machining center is a high degree of mechanical and electrical integration of products, workpiece clamping, the CNC system can control the machine according to different processes automatically select, replace the tool, automatic knife, automatically change the spindle speed, feed, etc., can be completed drilling,

- Q: 2.5 axis machining center and 3-axis machining center What is the difference

- The machining center is a machine tool with B-axis linkage and C-axis linkage which can be used for turning and milling. It can be said that all or most of the machining of a part can be completed on the above-mentioned turning and milling machine, so it is also called small production line

- Q: Comparison of CNC milling machine and CNC machining center machine differences

- The machining center has the function of automatic exchange of tools. By installing different tools in the magazine, it can change the machining tool on the spindle by means of automatic tool changer in one clamping, realize drilling, boring, hinge, tapping,

- Q: 850 processing center servo motor how many watts

- Domestic servo motor generally use N.M calculation, the general use of foreign KW do not know which equipment is your manufacturer, what is the servo motor brand.

- Q: How to judge the quality of the processing center

- There are several aspects of the machining center: the rigidity of the machine, the rigidity of the shaft, the positioning accuracy of the X, Y and Z axes, the repeated positioning, the relative straight angle of each axis, the stability of the bed, the workpiece

Send your message to us

Auto Polishing Peeling and Grinding CNC Machine JN-T8/D8/D10 for Prouding Faucets

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches