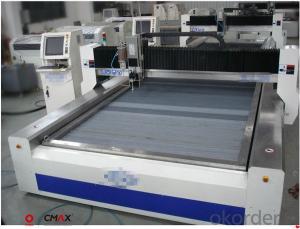

Vertical Machine Centre

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2566 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden package |

| Delivery Detail: | 50days |

Specifications

1.High efficient

2.Easy for operation

3.ATC

4.CE certificate

Machine features:

1) the main machine components(machine bed ,sliding sadder ,worktable)have adopted the structure of thermal symmetry and thin-walled

main stock with multi-layer ribs. arch” shape column with high rigidity goes through optimized treatment by finite element analysis to guarantee

the best rigidity;

2) the adoption of C3 grade precise ball screws and the use of special bearing on the ball screw with pre-pull treatment as well as laser

detective compensation have ensured the rigidity and precision.

- Q: How much is a small processing center?

- First, you want to confirm the size of your processed product, how much or small processing center to meet your requirements?

- Q: Machining center with an end mill milling side of the surface when the collapse is caused by what causes.

- Machining center with the end mill milling side of the surface should be a shock pattern, the main may be too long tool clamping length, or processing margin is too large, or the accuracy of the tool or spindle, when using the end mill Note the following:

- Q: How is the center of the processing center?

- 2. Turn to handwheel mode For example, to find the first Y to find the edge of the workpiece to the middle of the first close to the Y side of the end, such as the first close to + Y start the first hand wheel speed is adjusted to 0.1 is 10 when the fast when close to the edge

- Q: What does metal processing machinery include?

- , Storage equipment, heavy machinery and equipment, etc .; Measuring equipment: precision measurement, optical measurement, testing machine, sensors, etc.

- Q: Eight-axis machining center of the eight-axis generally refers to which several shafts, respectively, how to say? Thank you!

- Class five axes or more of the machine called the "X-axis five linkage machine"

- Q: Five-sided machining center and five-axis machining center What is the difference

- Pentahedral processing center, refers to the use of composite milling head, also said that his milling head can be unloaded, fitted with composite milling head, milling head can turn angle. That is, in addition to the table outside the surface is not good processing,

- Q: Farrah system processing center PS1016 no EOB alarm what it means

- FANUC system keys used:

- Q: The difference between CNC engraving and machining center

- Spindle maximum speed (r / min): Machining center 8000; carving carving machine is the most common 240000, high speed machine minimum 30000; engraving machine is generally the same with the engraving and milling machine, for high light processing engraving machine can reach 80,000, but that use

- Q: Vertical Machining Center

- Machining Center (English abbreviated as CNC full name for the Computerized Numerical Control): with a magazine and automatic tool changer of a highly automated multi-function CNC machine tools.

- Q: How to judge the quality of the processing center

- The roundness test roundness, there is a small complex surface test machine in dealing with the stability of the large amount of time.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | North America Eastern Europe Southeast Asia Mid East Western Europe |

| Company Certifications | ISO9001:2008 English Version;ISO90001:2008;CE Certificate;CE Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | English, Chinese |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

Vertical Machine Centre

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2566 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords