Horizontal Maching Center Model HMC630/800 with Siemens/Fanuc/Mitsubishi System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The horizontal machining center has inverted T structure, high spindle speed, strong rigidity and large torque. This series of machine tools has

perfect performance, stable accuracy, and reciprocating exchange of worktables. It is suitable for processing various types of box parts and two-

dimensional and three-dimensional surfaces. It is the key equipment for processing box parts in machinery, automobile, ship, textile machinery,

printing machinery, agricultural machinery and other industries.

System option:Siemens / Mitsubishi / Fanuc

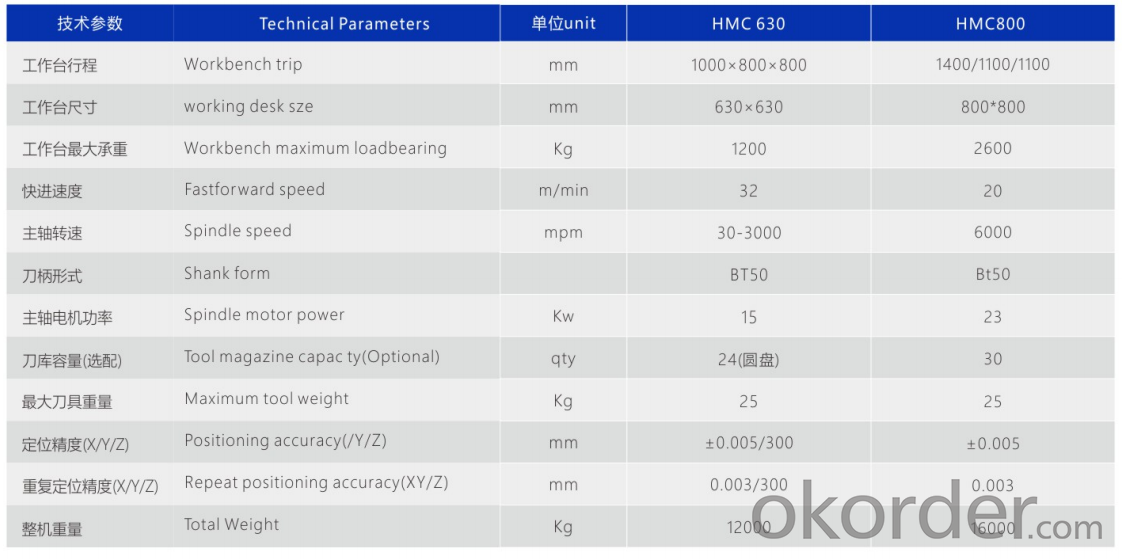

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: The difference between the heart and the milling machine, I feel like almost! Is not the diameter of the processing machine to be smaller?

- Simply speaking, take the heart of the lathe tool does not move, the spindle with the workpiece to do interpolation movement.

- Q: 850 processing center how much money one

- Machining center points hard rail and rail, this depends on what you want.

- Q: What is the machining center? The

- 4, the processing of high precision, stable and reliable processing quality, numerical control device pulse equivalent is generally 0.001mm, high-precision CNC system up to 0.1μm, in addition, CNC machining also avoid the operator's operational errors;

- Q: What is the M code of the Mitsubishi Machining Center?

- M14 is the spindle reversal and the cutting fluid is open.

- Q: Is there a need for a tooling center?

- To produce high-grade products, in addition to a good machine, but also need good auxiliary equipment, such as knives, knife, workpiece probe and so on.

- Q: CNC, machining center

- CNC milling machine has three servo shafts, no magazine.

- Q: What is the meaning of CNC machining center?

- CNC machining center is a tool with a knife and can automatically replace the tool, the workpiece can be a certain range of a variety of processing operations CNC machine tools.

- Q: Beijing precision machining center CNC machining center features what role

- System, this CNC machine tool movement and auxiliary action will be issued by the NC system command issued by the control, but the NC system instructions are by the programmer they according to the workpiece material and processing requirements, Shenzhen cnc processing there

- Q: CNC machining center g51 scaling instructions. Suppose I'm a 20-round round Now I want to shrink to 10 rounds how to use this command. Such as

- (X, Y, Z) for the given center (X, Y, Z) for the zoom center, the graphics zoom to the original graphics P times; if omitted (X, Y, Z), then the program origin for the zoom center

- Q: How to judge the quality of the processing center

- The roundness test roundness, there is a small complex surface test machine in dealing with the stability of the large amount of time.

Send your message to us

Horizontal Maching Center Model HMC630/800 with Siemens/Fanuc/Mitsubishi System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches