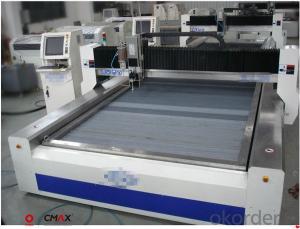

CNC Vertical Machining Center XH7146

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Case carton

- Supply Capability:

- 15 Cases Per Month carton/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | Standard sea worh package |

|---|---|

| Delivery Detail: | 30 days |

Specifications

1.the spindle with high speed and high precision

2.Linear guide way provides high speed, superior precision

After-sales service :

a.Free installation and debugging

b.Free operator training

c.Free maintenance within 1 year

d.Long warranty and technology support

- Q: What are the classification methods of the machining center?

- The machining center is usually classified by the relative position of the spindle and the table, divided into horizontal, vertical and universal machining centers.

- Q: 850 processing center how much money one

- We are currently using the huge 850 processing center, stable performance, this processing center is probably not expensive.

- Q: How does the tool radius compensation of the machining center determine positive and negative

- G42 is relative to the direction of the tool forward to compensate, called the right knife to fill.

- Q: Number of CNC lathes, controlled bed and machining center?

- CNC milling machines are generally processing parts of the waist hole, keyway, plane;

- Q: What is the difference between gantry milling machine and gantry processing center? Mainly from the function and processing objects to explain the difference.

- Ordinary not to mention, the general accuracy of poor efficiency is low, but the configuration side milling head, for some special purpose parts, you can have a high processing efficiency!

- Q: What is the M code of the Mitsubishi Machining Center?

- M14 is the spindle reversal and the cutting fluid is open.

- Q: What is the machining center?

- Which greatly reduces the workpiece clamping time, measurement and machine adjustment and other auxiliary process time, the processing of the shape is more complex, high precision requirements, frequent replacement of parts with good economic results.

- Q: How about Cheong Cheong Machining Center

- If you want to and Europe and the United States and Japan and South Korea's ratio, it is a bad grade, and the domestic ratio is still more competitive!

- Q: What brand of domestic machine tools? Is there a five-axis machining center

- In the foreign CNC technology to high-speed, precision, multi-axis, the overall trend of compound development, China's CNC machine tools, high-speed processing technology, precision machining technology, five-axis linkage and composite processing technology has made a breakthrough, breaking the foreign monopoly and blockade

- Q: What is the use of the processing center?

- Machining center is a high degree of mechanical and electrical integration of products, workpiece clamping, the CNC system can control the machine according to different processes automatically select, replace the tool, automatic knife, automatically change the spindle speed, feed, etc., can be completed drilling,

The principal products of us are various models of hydraulic presses (four-column three-girder hydraulic presses, four-column two-girder hydraulic presses, frame hydraulic presses and one arm hydraulic presses), vertical lathes and milling machines. We are engaged in the design, manufacture and provision of all kinds of hydraulic machine tools and related technical services. Our products have been widely used in many fields, such as automobile, metallurgy, spinning machine, plastic, latex, ceramic, powder and refractory material.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | North America Eastern Europe Southeast Asia Mid East Western Europe |

| Company Certifications | ISO9001:2008 English Version;ISO90001:2008;CE Certificate;CE Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | English, Chinese |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

CNC Vertical Machining Center XH7146

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Case carton

- Supply Capability:

- 15 Cases Per Month carton/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords