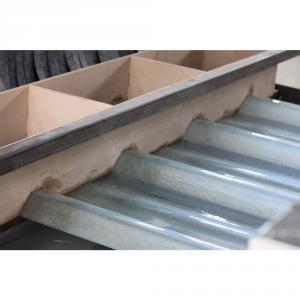

Screw Pump Rotor Whirling Milling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Screw rotor whirling machine:1.Processing threads, worms,screws, screw pump rotor

2.High efficiency, precision

3.Low cost

Thread whirling machine was used to manufacture threaded spindles, rotors for eccentric pumps,progressive cavity pump rotors, vacuum pump rotors, screw type compressors, tie bar threads, ball screws, worm shafts and steering worms.

Whirling is a particular type of milling that is position rotates at high speeds around a slowly turning workpiece. The cutting plane on the tools' cutting edges is adapted to the respective thread pitch by tilting the thread-whirling head around its vertical X-axis. The tool's large tilting range enables users to realize high thread pitches and to cut right-handed and left-handed threads. The radial setting of the whirling head determines the thread depth. The tool's design permits down-cut, conventional and up-cut milling.

Provide a number of advantages over traditional single-point threading, including increased productivity, faster set up times, no extra costs for finishing treatment, superior chip control and increased tool life over conventional tools.

Thread whirling features:

1. The machine is our company's own R & D design, with independent intellectual property rights (with six national patent)

2. Applicable to automobiles, motorcycles, machine tools, gearbox, chemical machinery, plastic machinery, construction machinery and other industries

3. Machine tool used FANUC 0i—Mate—TD system to achieve 4-axis rotary 3-linkage control to X, Z, C axis, whirling milling head axis

4. Machine Tool Spindle Servo Motor is to be the largest ratio 1:100 by harmonic reducer; to achieve the precise positioning of the spindle indexing and powerful cutting

5. Machine milling head used with the international advanced level of machine whirling milling turning, milling in multiple knives without re-grinding

6. Using high precision flexible hydraulic chuck to ensure the worm run out accuracy

7. Tool spindle speed can be adjusted so that user can choose the best cutting speed for work pieces with different diameter and material

8.Automatic involute milling for the machining of both ends of the worm, no need for secondary process

9.The precision of the worm made by CNC machine is up to level six (including all parameters);surface roughness Ra0.8 MAX

10.No limitation of number of threads of worm for Whirlwind milling process, the max helix angle up to ± 25 °

- Q:Which of the lathes are included

- Ordinary lathe processing object wide, spindle speed and feed the adjustment range, can process the workpiece inside and outside the surface, end and internal and external thread.

- Q:The use of CNC lathe G76

- M: indicates that the number of repetitions of finishing is indicated by two digits from 01 to 99;

- Q:CNC milling machine is not a CNC lathe, what is the difference between them?

- CNC milling machines are at least 3 axes (XYZ, etc., mostly 5 axes), while the general CNC lathe is only 2 axes (ie X, Z). In general, the lathe will be more difficult than the milling machine, if the CNC lathe will be better than the milling machine, technically,

- Q:What is the lathe tray?

- The turret is equipped with a knife holder for the installation of the turning tool.

- Q:What is the material of the lathe tool?

- Z direction only need to knife into the end can be, enter 0.000, can not go to cut the end. For the X direction can be cut again, and then measured.

- Q:What brand of ordinary lathe easy to use

- Shenyang is good, Shandong is also the production of machine tool manufacturers more provinces, you can go to see the main or look at the quality, cost-effective, and whether the timely service

- Q:What are the daily maintenance of the lathe?

- 3, scrub wheel frame, to ensure that the wheel frame, gear clean and no trace.

- Q:What wide number of 980T clear knife fill when prompted not to enter?

- GSK980TDA simulation software settings in the parameters of how to open the switch? I press the LD on the alarm that has been opened but not open so that can not modify the parameters and input knife compensation Is there a place to set up?

- Q:What is the difference between the so-called fine car and rough car?

- Roughing is mainly to remove most of the machined surface of the machined surface, in the allowable range should try to choose a large depth of cutting and feed.

- Q:How does the CNC lathe front knife and rear turret programming differ

- The front knife and rear turret programming is the same, clockwise circular interpolation G02 and counterclockwise circular interpolation G03 direction is based on the right hand Cartesian coordinate system, first determine the positive direction of the Y axis, and then from

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Screw Pump Rotor Whirling Milling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches