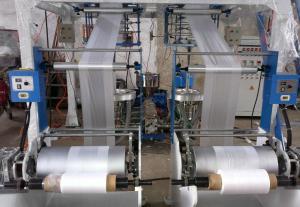

PE Two-Color Mulch Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of mulch film blowing machine:

mulch film series blowing lines are developed by importing Japanese technology and combining with the situation of our country. It is mainly used to produce double colors plastics mulch and agricultural film, such as white and black (or silvery white) film. It resolved successfully many difficult problems for some machines such as easy mix materials, indistinct in color limits, not even in thickness, easy tearing in joint places, etc. It can also be used to produce the double layers film by changing the die partially.

The line has been improved for many times, and it has many merits now, such as the reasonable design, compact structure, convenient operation, especially the main motor has been changed into frequency conversion and after re-equipping the line, the efficiency of the line is increased and the energy consumption is reduced, the whole line function is more advanced and reasonable. And we can also carry full frequency conversion timing and other special equipping according to the consumers requirements.

Technical Parameters

Materials: LLDPE, LDPE, HDPE, MLLDPE

Film Width: 600-1200mm(Unfold)

Thickness: 0.004-0.1mm

Max. Output: 70kg/h

I Single Screw Extruders SJ-45/30 (2 sets)

A. Diameter of Screw: φ 45mm

B. L/D: 30: 1

C. Material of Screw: 38CrMoALA

D. Screw Nitrogen Treatment Depth: 0.4-0.7mm

E. Surface hardness: HV950

F. Material of Barrel: 38CrMoALA

G. Barrel Nitrogen Treatment Depth: 0.4-0.7mm

H. Surface hardness: HV≥ 940

I. Barrel Cooling Method: Air-cooling(3 zones)

J. Barrel Heating Method: Casting aluminum heating (3 zones)

K. Barrel Temperature Controll: Auto-controll, LCD Screen,

2. A. Main motor: 15kw, With Inverters

B. Inverters: Sino-Japan cooperation

3. Heating Method

A. Casting aluminum heater

B. Cooling Method: Auto constant temperature system, air-cooling

4. Reducer

A. Material of reducer: HT200

B. Lubricating Method: Constraint oil Lubricating

C. Material of Gear: 20CrMoTi

D. Processing techinics: Forging, Grinding, Nitrogen: HV≥ 750

5. Aptitude digital temperature-controlling equipments

6. Operation: Dest type electrical controlling tank

7. Equiped screen changer: 2 sets, prolong the time of screen changer

II Diehead

1. Material of Die: 5CrNiMo

2. Type: Double-layer coextrusion inner composite spiral die

3. Diehead Diameter: 250X1.5mm

4. Heating Method: Casting aluminum heater

5. Temperature Controll: Auto-controll

6. Zones: 3 zones of die

7. Voltage: 380V/50Hz

8. Power per zone: 3kw

9. Feeder method: Center feeder

10. Prepare parts: Heating stick, tools

III Air Ring

1. Air Ring Type: Dyke Type high wind capacity, Angle adjusted.

2. Air Ring Outdiameter: 1000mm

3. Blower power: 1.5kw

4. Air Ring Material: Casting aluminum

5. Tube: Plastic tube

IV Take-up system

1. Take-up type: Disassembly structure, Operation plate, Handrail.

2. Take-up roller specification: 160× 1300 mm

3. Take-up roller material: Rubber

4. Take-up roller center: 5800mm

5. Max. Take-up speed: 120m/min

6. "A" Board Type: Fense type board

7. "A" Board Material: Steel frame type, Galvanization tube

8. Adusting Method of

9. Take-up motor power: 1.1kw, Frequency conversion

V Winding equipment

1. Winding Method: Double flat and friction winding

2. Max. Winding speed: 120m/min

3. Motor power: 100.4/8

- Q: Portable continuous refining machines and pneumatic oil filters that good

- Second: the portable oil filter is generally only filter impurities, there are mainly 5 types, (1) LY precision oil filter car with filter filter impurities (2) LY frame pressure oil filter using pressurized fluid through the filter plate, filter impurities (3) bag (cloth) oil filter. The bag or cloth filter impurities (4) ceramic filter, ceramic filter impurities, acid and alkali (5) centrifugal oil filter, mainly through centrifuge rotating centrifugal force, let out the impurities, and dehydration washing machine principle. Summary: the top 4 portable oil filters are mainly used for filtration of industrial oils. The latter fifth types of centrifugal oil filters are mainly used for filtering edible oils.

- Q: How about the rental fee for vacuum oil filter?

- Of course, buying cheap things that will last two or three years of life can be a waste. As for you, if you really want to rent, only in the vicinity of the local oil filter companies to buy, ask to see how specific people rent, how much money, this is to talk to each other, bargaining.

- Q: What's the difference between a heated plate and frame oil filter and an ordinary plate and frame oil filter?

- Characteristic:1, super demulsification dehydration and degassing system, with large volume, enhanced three-dimensional flash tower and thin film evaporation technology and a large area of multi-level oil water gas separation technology, can fast remove the oil in the water, gas and light hydrocarbon.2, the use of high quality filter original and sealing materials, corrosion resistance, high temperature resistance, good mechanical strength, to meet the high viscosity of the filter oil needs higher temperature requirements, expanding the range of its purification of oil.3 、 precise multi-stage filtration system can effectively remove mechanical impurities in oil.4 、 advanced pressure protection device, liquid level control system, to avoid the misoperation of the equipment.5 、 perfect automatic and manual electric heating temperature control device, automatic separation cooling device, simple operation, safe and reliable.6, the machine can also be used to meter and timers, users can carry out automatic measurement of fuel quantity and working time.

- Q: Working principle and operation instructions of vacuum oil filter for oil press

- The water vapor entering the condenser is cooled and then returned to the original water. The oil in the vacuum heating tank is drained into the static filter by the oil pump and filtered out by the filter oil paper or filter element. Thus, the whole process of removing impurities, moisture and gas in the oil by the vacuum oil filter is completed, so that the clean oil is discharged from the oil outlet.

- Q: How to use the centrifugal oil filter properly?

- 4 bootStart the main engine. After running for a period of time, stop and check if the parts have rubbing. If you have, you must find out the cause and eliminate it.5 operation check1) is the temperature and separation performance of the machine in steady state?.2) there is no leakage of the sealing parts.3) whether there is any increase in vibration or noise; if it is increased, the cause must be ascertained.4) the working current of the motor is normal, whether the current fluctuates greatly.5) should always check the main bearing temperature, the temperature less than 75 DEG C, the temperature difference is less than or equal to 35 DEG C, bearing temperature is too high to be down to check the cause and shall be excluded.

- Q: Has anyone filtered vegetable oil with a plate and oil filter?

- If it is to filter edible vegetable oil, the material, production conditions, the environment has many requirements, after all, involving food safety, must be all stainless steel material.Finally, the vegetable oil is filtered by plate and frame oil filter. The filter paper and filter paper must be made of pure cotton fiber, so as to reduce and eliminate chemical pollution.

- Q: Operating principle and characteristics of electrostatic oil filter

- Reduce equipment failure, reduce downtime, save the maintenance cost A. to extend the service life reduce replacement costs 44.7% B. to prevent downtime losses caused by 22.3% C. 19.4% D. to reduce the equipment investment and reduce friction parts, energy saving 5.5% E. enhance the production efficiency of the economic benefits of 4.1% F. to reduce labor costs 2% g. lubrication to reduce oil consumption 2% three, greatly extend the life span of oil (5 ~ 7), reduce the oil yield (80% ~ 90%), protect the environment. Four 、 with perfect automatic protection device, unmanned operation can be carried out continuously, the maintenance cost is low, and the economic effect is the best.Electrostatic oil filter processing efficiency is too low, the speed of processing oil is very slow, while the effect of micro filtration of water is not good, it depends on what you filter oil, which contains impurities

- Q: What is the influence of the vacuum degree of vacuum oil filter?

- In 2, when the bubble is much too high, oil separation chamber, the upper oil bubble pump is easy to be removed, thus oil reduced, and so on the pump itself has hurt.

- Q: The difference between plate type oil filter and automatic slag filter

- Plate type oil filter investment is relatively small, but the latter supplies high cost, the scene is dirty, oil consumption is higher, labor costs relative to more than one person's expenses.

- Q: The same function, one is installed in a part of a system, and the oil filter can move, do not need other devices can be completed independently

- 1, waste oil dehydration at present there are three main ways of the market: vacuum oil filter, dehydration, coalescence, oil filter dehydration (including poly vacuum dehydration), centrifugal oil filter dehydration.

Send your message to us

PE Two-Color Mulch Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords