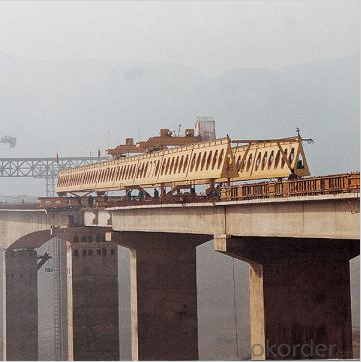

Bridge Girder Launcher, Bridge Building Crane, Bridge Construction Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bridge Girder Launcher, Bridge Building Crane, Bridge Construction Machine

Product Detail

Basic Info

Model NO.: Bridge Girder Launcher HZQ

Type: Bridge Crane

Application: Construction Usage

Sling Type: Wire Rope

Power Source: Electric

Certification: ISO9001: 2000, CE

Condition: New

Brand: Huazhong

Item: Bridge Girder Launcher Hzq-50-160b

Span(M): 50

Lifting Capacity(T): 160

Crane Moving Speed(M/Min): 2.7

Trolley Moving Speed(M/Min): 4.5

Trolley Lifting Speed(M/Min): 0.8

Girder-Carrying Speed of Rear Part(M/Min: 0-9

Applicable Curve Radius(M): R350

Power(Kw): 96

Export Markets: Global

Additional Info

Trademark: HUAZHONG

Packing: Standard Export Package or as Your Request

Standard: ISO9001: 2008, CE

Origin: Zhengzhou, Henan, China

Production Capacity: 200 Sets Per Year

Product Description

1. Application range of Bridge Girder Launcher

The bridge girder launcher is designed for highway and railway. According to the situation of present railway with less sub grade, more bridges and tunnels which connected too closely, our company design and manufacture the new box-girder bridge girder launcher with double girder. It is mainly used for hoisting (lifting) of concrete girder in bridge construction (bridge building) of general railway and highway.

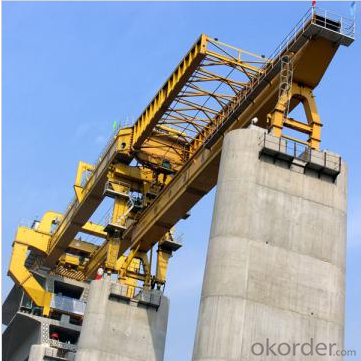

2. Main features and advantages of Bridge Girder Launcher

According to users' demands, the new type Bridge Girder Erection Machine which integrates carrying with erecting is designed. Also we apply for national patent (The patent No. Is 02228146.0)

Features:

A. The machine can accomplish the girder's carrying with erecting at the same time.

B. The machine can erect 4 pieces of girders with another two cranes one day, saving construction cycle.

C. Another advantage: If the concrete girder is between the two piers, just exchange the front and rear legs, it can continue to work, no extra assembly, shortening construction period.

3. The design basis of Bridge Girder Launcher

We design the bridge girder launcher according to the rules of the newest machinery and crane in China, the rules are following:

A. < Cranes--Test code and procedures> GB5905

B. < Safety regulations for hoisting machinery> GB6067 < Code for design of steel structures> GB50017

C. < Safety technology specification for special equipment> TSG Q7002\Q0002

D. < Code for construction and acceptance of steel structure> GB50205

E. < Standard for quality inspection and evaluation of steel structure engineering> GB50221

F. < Weld Outer Dimensions for Steel Construction> GB10854

G. < Code for construction and acceptance of electric equipment installation engineering> GB232

H. < General technical requirements of assembly> JB/ZQ400.9

I. < Mechanical properties of fasteners> GB3098

4. Main design requirements of Bridge Girder Launcher

Technical index;

Safety factor 1.5

Using grade: U3

Load state: Moderate

Working grade of the whole machine: A3

Working grade of the mechanism: M4

Working condition and requirements of design etc.

5. The quality control in Bridge Girder Launcher manufacturing process

Technology file drawing and project are handed to production department which assorts with related department and quality department to process, manufacture, control, check and accept of product.

The workshops do the following work according to drawing:

A. Blanking splicing(technology and requirements of blanking splicing)

B. Assembling welding(welding procedure card, welding technology qualification and welding record)

C. Mechanical manufacture(mechanical manufacturing card)

D. Finishing time of manufacture and patrolling card

E. Assembly(assembly technology)

F. Checking descriptive chart(controlling the geometry size and key part).

- Q: the answers are in the parenthesis but i dont know how to get the answer, can someone help?- A boy does 250 J of work in 22 sHow much power does he deliver? (11.36 W)- A crane lifts a 48 kg load at a speed of 1.4 m/sHow much power was delivered? (659 W)

- just in the movies just go in a little section in the corner and with nobody around but if its your first time let him finger you becuz its less painful and you dont have to make all that noise during having sex just be quiet and decrete

- Q: i have been trying to connect my ps3 to the internet to play online but i cant seem to bridge connect the two of themhelp please.

- I think you may have posted in the wrong sectionI know Cabela's has some nice bed linens but they were way out of what I was willing to payMy last set came from Wal MartBut I don't know the difference between a douvie and a dust skirt.

- Q: I Want to do something that's meaningfulsomething that I won't regret doingsomething I won't later call a waste of timeLike a craft, a projectanythingThanks in advance!VOTE GEORGE LOPEZ U.S PRESIDENTPIERS MORGAN AND SIMON COWELL'S BIGGEST FAN

- Depends on about 50 things

- Q: I have a Squier Strat Affinity SeriesI plan on replacing the pickups, most, if not all of the electronics, the bridge, the tuning machines, and i also want to refinish the guitarI have also thought about replacing the neck, but am curious to whether or not buying an authentic fender neck would make enough of a difference to be worth the money.

- raisins, fruits like apples and vegetables like maybe a spinach salad

- Q: a crane lifts a marble block with a mass of 500kg to a height of 50metres in 2.5 minuteswhat is the power output of this crane? please help and explain your thinking thank you ! :)

- 2.5 minutes 150 seconds.power is in watt which is joules per seconds thus you use the mass and the height to find energy which is in joulesI believe it is potential energy! Umgh h being the height 50 m and m being the mass 50 kg and g is gravity which is 9.8 so U50509.8 24500 J so power is equal to 24500/150 163.33 W

- Q: what is the function of tie rod in a heavy vehicle?

- Machine shop jobs if you work on the floorMy brother and my husband both have them and the only people they have to interact with are their coworkers.

- Q: i have nothing to do and i am boredcan someone please give me some things to do to pass my free time.

- i cant see it but can imagine like the other answer,i have messed about on building sites as a teenager,but i wouldnt do it now,you just dont realise the dangers when your that age,but bye what the story is saying there they worked there ,and i agree with what they said about the services would have had to pick up the pieces if anything had gone wrong which by the sound of could of.i still would of liked to of seen it though.

- Q: Two construction cranes are each able to lifta maximum load of 10000 N to a height of150 mHowever, one crane can lift that loadin 1/4 the time it takes the other.How much more power does the faster cranehave?

- I have known this since I was in my teens! Old news, but an excellent question never the less! Right now I am drinking club soda! sm

- Q: ok so what order do you generally notice losing weight in?oh and lately ive been exercising more, and im gaining muscle in my calves, I DONT WANT THIS, so what should i be doing in reguards to exercising, to lose weight, not gain muscle?

- As you lose weight you will be gaining muscleTry to work out only parts of your body that need it.

Send your message to us

Bridge Girder Launcher, Bridge Building Crane, Bridge Construction Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords