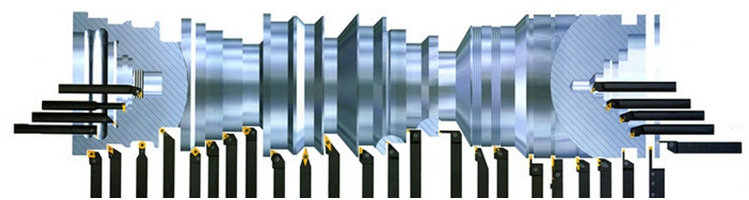

Turning Tools Metal Lathe Cutting Tools Diamond Cutting Tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of cutting tool:

Including external turning tool holders, boring bars, threading holders, grooving holders, cartridge and micro turning tools.

As the first product, our turning cutting tools has the following impassable advantages:

· our turning cutting tools cover a wide application range with a full line-up of ISO cutting tools that produce high quality and high precision cutting tools and parts for all manufacturers’ requirements.

· Main cutting tool’s type include external turning tool holders, boring bars, threading holders, grooving holders, cartridge and micro turning tools.

· All the spare cutting tools are made by ourselves, stable and controllable quality can reduce the wear of the insert and adjustment time.

Application

· Mainly use for turning machine, boring, grooving and threading in NC Lathe.

- Q: I use acetylene oxygen to weld a common lathe blade. Why does the blade keep cracking

- Welded structure of cutting tool should have enough rigidity, enough rigidity is the appearance of the maximum allowable size, and USES high strength steel grade and to ensure that the heat treatment. Carbide blade should be fixed firm, for example, cemented carbide welding blade should have enough degree of fixation, it is to rely on groove and welding quality to ensure that, generally speaking, according to the shape of blade and the cutting tool geometry parameter choice blade groove shape. It is necessary to inspect the blade before the carbide blade is welded to the blade, and the blade must be inspected first. Hard alloy welding surface must not have serious carburizing layer, at the same time should also will carbide blade surface and cutter bar set of dirt to clean, to guarantee the welding. In order to ensure the welding strength, choose the suitable solder. During the welding process, good moisture and liquidity should be guaranteed, and the bubbles shall be eliminated, and the welding and alloy welding surfaces shall be fully in contact with the welding phenomenon. Welding flux choice: borax industry, can be used in the drying furnace shall be carried out before use dehydration processing, then crushed, sieve to remove mechanical impurities in again. Use mesh compensation pads. For example: in the welding of titanium high low cobalt fine alloy and welding of long and thin blade, in order to reduce welding stress, and sheet thickness of 0.2 ~ 0.2 mm can be used or mesh aperture 2 ~ 3 mm spacer mesh compensation on welding.

- Q: What is the best vehicle for threading

- Depending on what kind of material you are working on, the thread on the cast-iron material is hard alloy with YG, and the steel parts of the car are made of hard alloy of YT. The depth of the tool with the high hardness of the material can choose the small point, the method that can take the small knife frame when the size of the cross section is large. The Angle of the knife should be more than half degrees of the Angle of the tooth, the rear Angle of the blade is equal to the Angle of the Angle and the Angle of the Angle. The center height of the edge of the knife is the center of the workpiece, and the Angle bisector is perpendicular to the axis of the workpiece.

- Q: How many lathe knives are there?

- The type and purpose of the tool The blade is the most widely used single blade cutter. It is also the basis for learning and analyzing various kinds of knives. The lathe is used for various kinds of lathe, processing outer circle, inner hole, end face, thread, car slot and so on. The structure of the tool can be divided into the overall car knife, the welding tool, the lathe tool, the turning tool and the shaping tool. The use of indexable turning tool is becoming more and more extensive, and the proportion of the blade is gradually increasing.

- Q: What are the main angles of the car knife? What's the difference?

- Main rear Angle: the Angle between the blade and the cutting plane. The effect is to reduce the friction between the blade surface and the workpiece. It also affects the strength and sharpness of the blade as well as the anterior horn. Selection principle and rake Angle are similar, is generally 2 to 8 °

- Q: The choice of the threading tool and the residual choice of the turning process

- Commonly used 60 ° thread is metric thread that gb, 55 ° is inch thread and pipe thread (another 60 ° pipe thread is not commonly used), 30 ° is trapezoidal thread, 40 ° is the worm. And the serrated thread. The diameter of a triangle thread is usually 0.2 to 0.3 mm smaller than the standard metric. The compression of thread cutting tool will make the diameter of the workpiece be coarser because of the tip of the triangle thread. The same is true for car peing and thread. In the case of the trapezoidal thread and worm, the small 0.2 mm is due to the measurement of the diameter to meet the standard.

- Q: The threading tool always breaks down

- The threading tool is always broken: The two rear corners are as small as possible, but be sure to have two blades of oil blunt. Sometimes there are patterns:

- Q: What kind of alloy is the car knife used?

- Tungsten cobalt class (WC + Co) carbide (YG) is composed of WC and Co, it has high bending strength toughness, good thermal conductivity, but poor heat resistance and abrasion resistance, mainly used for processing cast iron and nonferrous metals. Fine grain of YG carbide (such as YG3X, YG6X), in the cobalt content in phase at the same time, its high hardness, wear resistance than YG3, YG6, strength and toughness is a bit poor, suitable for processing hard cast iron, austenitic stainless steel, heat-resistant alloy, hard bronze, etc.

- Q: What is the Angle of the threading tool?

- Pipe threads have 55 degrees of non-sealing and 55 degree seals. The diameter of the thread is guaranteed by controlling the total depth of the multiple feed. Every time when threading cutting depth volume is smaller, and the total amount of cutting depth can work according to the calculation of the thread tooth high (high working tooth = 0.54 x artifact of pitch, the unit is mm), controlled by skateboard dial in roughly, and with the aid of the thread gauge to measure. Threading requirements: 1) the blade of a car knife is equal to the Angle of the thread profile. 2) before the Angle between 0 = 0 °, coarse thread in order to improve the cutting condition, available with positive rake Angle of cutting tool (gamma 0 = 5 ° ~ 15 °).

- Q: What's the difference between a car knife and a milling cutter

- Reamer: two kinds of reamer and reamer. The blade of the coarse reamer is small, the chip is empty and the blade is large, and there is a helical chip groove on the edge of the blade, so as to prevent the shavings from getting too much in the thick. The reamer has a large number of blades and a small edge to ensure the quality of the pheasant hole. The size of the commonly used reamer is l: 50, 1:20, 1:5

- Q: What is the difference between the Angle of the lathe and the Angle of work

- The root cause of the Angle change is the change in the position of the cutting plane, the base plane and the orthogonal plane, so the Angle of work is also called the practical Angle.

Send your message to us

Turning Tools Metal Lathe Cutting Tools Diamond Cutting Tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords