Diamond Plate Aluminum Tool Box

Diamond Plate Aluminum Tool Box Related Searches

Aluminum Diamond Plate Tool Box Aluminum Diamond Plate Box Diamond Plate Box Aluminum Aluminum Diamond Plate Truck Box Aluminum Diamond Plate Boxes Aluminum Tool Plate Aluminum Diamond Plate Cabinets Aluminum Tread Plate Tool Box Aluminum Tooling Plate Polished Aluminum Diamond Plate Aluminum Diamond Plate Mailbox Diamond Plate Aluminum Polish Aluminum Diamond Plate Panels Buy Aluminum Diamond Plate Aluminum Diamond Plate Roll Diamond Plate Sheet Aluminum Aluminum Dimond Plate Aluminum Diamond Plate Fuel Tank Black Diamond Plate Aluminum Aluminum Diamond Plate Cooler Aluminum Diamond Plate Pegboard Diamond Checker Plate Aluminum Aluminum Black Diamond Plate Aluminum Diamond Deck Plate Diamond Tread Plate Aluminum Welding Aluminum Diamond Plate Aluminum Keyboard Plate Aluminum Diamond Plate Polish Black Aluminum Diamond Plate Diamond Plate Aluminum TrimDiamond Plate Aluminum Tool Box Supplier & Manufacturer from China

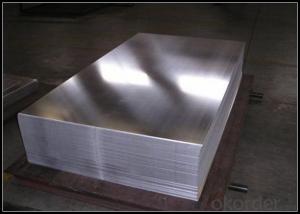

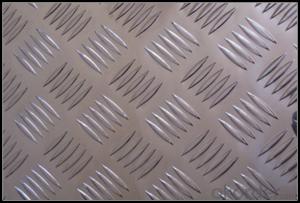

The Diamond Plate Aluminum Tool Box is a high-quality storage solution designed for various tools and equipment. Made from durable aluminum, it features a diamond plate design that not only adds a sleek aesthetic but also provides extra strength and protection. This tool box is perfect for professionals and enthusiasts alike who require a reliable and sturdy storage option for their tools.The Diamond Plate Aluminum Tool Box is widely used in various scenarios, such as workshops, garages, and construction sites. Its robust construction ensures that it can withstand the wear and tear of daily use, while the diamond plate design adds a touch of style to any workspace. The tool box is also suitable for personal use, providing a secure and organized storage solution for tools and equipment at home.

As a leading wholesale supplier, Okorder.com offers a vast inventory of Diamond Plate Aluminum Tool Boxes to cater to the needs of businesses and individuals. With competitive prices and a commitment to customer satisfaction, Okorder.com is the go-to source for purchasing this versatile and durable product.

Hot Products