Rippled Aluminum Sheets for Roofs - Bright Diamond Aluminium Chequer Plate for Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Bright Diamond Aluminium Chequer Plate for Toolbox

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Bright Diamond Aluminium Chequer Plate for Toolbox

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Bright Diamond Aluminium Chequer Plate for Toolbox

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

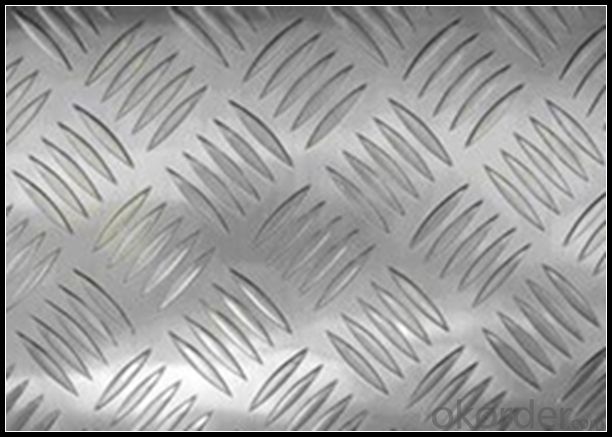

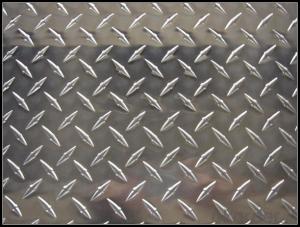

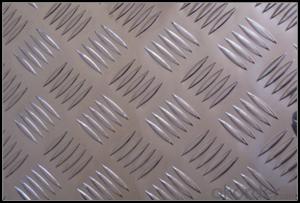

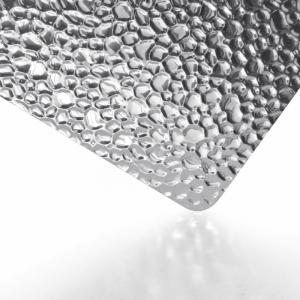

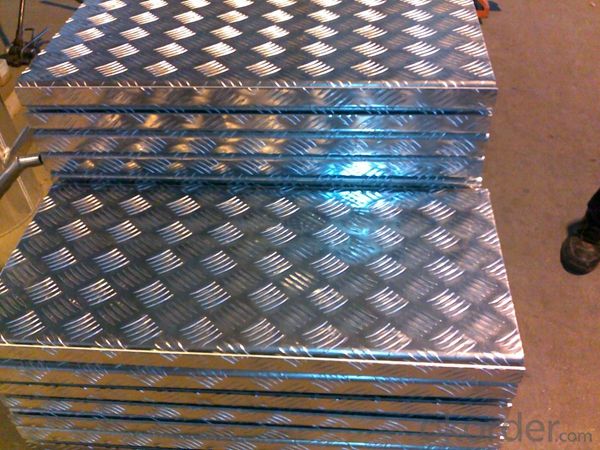

5. Image of Bright Diamond Aluminium Chequer Plate for Toolbox

6. Package and shipping of Bright Diamond Aluminium Chequer Plate for Toolbox

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: What are the different surface finishes available for aluminum sheets?

- Some of the different surface finishes available for aluminum sheets are mill finish, brushed finish, anodized finish, and embossed finish. Mill finish is the natural appearance of the aluminum without any additional treatment. Brushed finish involves brushing the surface to create a textured appearance. Anodized finish involves an electrolytic process that forms a protective layer on the surface and can be colored. Embossed finish involves creating patterns or designs on the surface using pressure or heat.

- Q: Can aluminum sheets be used in the automotive industry?

- Yes, aluminum sheets can be used in the automotive industry.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, meaning it can be easily manipulated without breaking or cracking. This property makes it ideal for various applications where flexibility and customization are required. Aluminum sheets can be bent, folded, rolled, or formed using a variety of techniques such as press brakes, rollers, or specialized forming tools. This versatility allows for the creation of complex shapes and structures, making aluminum a popular choice in industries like construction, automotive, aerospace, and manufacturing.

- Q: What is the weight of aluminium plate now?

- The proportion of pure aluminum is 2.702g/c square meters. General are aluminum alloy, the proportion of the different components, different, but the difference is not great.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. Aluminum is a popular material for roofing because it is lightweight, durable, and resistant to corrosion. It is also non-combustible, making it a safer option for roofing. Aluminum sheets are easy to install and maintain, and they can withstand harsh weather conditions such as heavy rain, snow, and wind. Additionally, aluminum is a sustainable material, as it is 100% recyclable, making it an environmentally friendly choice for roofing. Overall, aluminum sheets provide a long-lasting and reliable roofing solution for both residential and commercial buildings.

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: (2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

- Q: How does the formability of aluminum sheet vary with different alloys?

- Variations in chemical composition and mechanical properties result in significant differences in the formability of aluminum sheet among different alloys. To enhance specific characteristics like strength, corrosion resistance, and formability, aluminum alloys are typically combined with elements such as copper, manganese, magnesium, and zinc. Aluminum alloys like the 1xxx series (pure aluminum) and the 3xxx series (manganese alloyed) are highly formable and commonly used for deep drawing applications. These alloys can be shaped into complex forms without cracking or tearing. In contrast, alloys with higher strength properties, such as the 2xxx series (copper alloyed) and the 7xxx series (zinc alloyed), generally have reduced formability. Although these alloys are often used in structural applications where strength is crucial, they require careful handling and processing to avoid defects during forming. Alloys in the 5xxx series (magnesium alloyed) offer a good balance of formability and strength. They are widely used in industries like automotive and aerospace, as they can be easily formed into different shapes while providing sufficient strength and corrosion resistance. It's important to note that the formability of aluminum sheet is not solely determined by the alloy composition. Other factors such as sheet thickness, forming temperature, and the specific forming process employed (e.g., deep drawing, bending, stretching) also influence formability. These factors interact with alloy properties to affect the formability characteristics of aluminum sheet. Therefore, careful selection of the appropriate alloy and process parameters is essential to achieve the desired formability for specific applications.

Send your message to us

Rippled Aluminum Sheets for Roofs - Bright Diamond Aluminium Chequer Plate for Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords