Aluminum tray

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

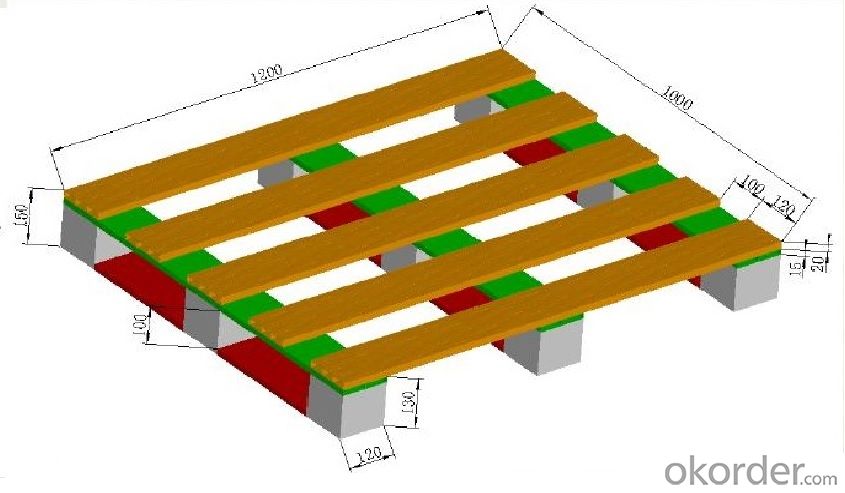

Please see more info as belows:

No. | Dimension(mm) | Weight(kg) | Alloy | Dynamic load | Static load | Load mode | Processing type |

1 | 1200×1000×153 | 14.84 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

2 | 1200×1000×150 | 14.38 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

3 | 1200×1000×150 | 21.56 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

4 | 1200×800×150 | 11.90 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

5 | 1200×800×150 | 17.62 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

6 | 1100×1100×150 | 14.39 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

7 | 1100×1100×150 | 20.96 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

8 | 1200×1000×150 | 14.13 | AL6061-T6 | 1.5t | 3t | Single side | Riveting |

9 | 1200×1000×150 | 18.60 | AL6061-T6 | 1.5t | 3t | Double side | Riveting |

- Q:How to handle the surface of the aluminum tube is bright, and will not have any impression after touching it

- Can be anodized by bright aluminum to meet your requirements.

- Q:Aluminium tube production and equipment. What are the production techniques and what equipment are needed? How much will it cost?.

- Sapa heat transfer (Shanghai) Co., Ltd. pipe division any electrical engineer, project and process engineer, technical director, proficient in German sholar welding pipe production line, welding of various high-frequency tubes (flat tube, rectangular tube, pipe) technology and equipment are very fine, well versed in the world's most advanced tubes (especially thin-walled aluminum tubes, wall thickness of 0.20-0.32mm) welding technology.

- Q:Are aluminum pipes more expensive than other materials?

- It depends on the specific material. Aluminum pipes are generally priced competitively compared to other materials used for piping, such as steel or copper. However, the cost may vary based on factors like size, thickness, and market fluctuations.

- Q:We use CNC machining, the best easy to process, the hardness is too low, not good (listen to others say that some aluminum foam will stick to the knife, and some processing is not bright). Online check is said 6063, but to the aluminum shop asked about, say is 6061, buy 50 kilograms first, try to do, but the boss said seems to be another kind, beg you prawns help ah

- The 3 and two lines (2024, 2017, 2011) and seven (7075, 7050) and relatively high hardness, Brinell hardness of about 120-150, the two kinds of materials for aviation aluminum, the price is more expensive (40-90 /KG) range, easy cutting, brightness is also good, but the effect of oxidation as six series. Have not heard who used to do the lamp can also be excluded.4, so you are the most correct is to choose six lines of aluminum to do, and 6061 and 6063, I suggest using 6063, because the 6063 oxidation effect is better than 6061. Currently on the market is 6061 more larger in diameter than the aluminum rod and tube of 20MM (and most not GB, GB material oxidation effect, stable performance, but because of you) the amount is too small, can not find manufacturers directly customized, GB is not a good buy material. Ask more and you should find 6063.

- Q:What is the difference between the extrusion process of seamless aluminum tubes and conventional aluminum tubes?

- The seamless aluminium tube is made by piercing extrusion, while the conventional aluminum tube is extruded by combined die. The short rod, high temperature, slow extrusion process, especially to control the "three temperature", aluminum rod, extrusion cylinder, and the mold must be kept clean, aging time and temperature are adjusted according to the wall thickness of a size of it

- Q:How are aluminum pipes manufactured?

- Extrusion, a well-known process, is employed in the manufacture of aluminum pipes. This process involves the passage of a heated aluminum billet or log through a specifically shaped die, resulting in the creation of a desired cross-sectional shape. The initial stage of the manufacturing process entails the careful selection of a high-quality aluminum alloy. Subsequently, the alloy is subjected to heating in a furnace, usually at temperatures ranging from 750 to 950 degrees Fahrenheit (400 to 500 degrees Celsius). This heating renders the material malleable and facilitates ease of shaping. Upon reaching the desired temperature, the aluminum billet is moved to the extrusion press. This press comprises a chamber for billet placement and a ram that exerts pressure to propel the billet through the die. The final shape of the pipe is determined by the die. During the billet's passage through the die, it undergoes plastic deformation, adopting the shape of the die opening. The application of high pressure by the ram ensures precise control over the pipe's dimensions and surface finish. Following extrusion, the aluminum pipe is subjected to cooling in either a water bath or an air cooling system. This cooling process leads to the hardening and stabilization of the pipe's shape. Subsequently, the pipe is cut to the desired length, using commonly a saw or other cutting tools. The concluding step encompasses any necessary finishing processes, such as straightening, deburring, or surface treatment. These processes are essential in guaranteeing that the aluminum pipe fulfills the required specifications and quality standards. Overall, the extrusion process enables the efficient and cost-effective production of aluminum pipes, characterized by consistent dimensions and exceptional mechanical properties. Consequently, aluminum pipes have gained popularity across various industries, including construction, automotive, aerospace, and plumbing.

- Q:Who knows the grease on the aluminium tube cleaning method

- You can only use neutral detergent such as detergent.

- Q:Which is the high price of 6063 and 6061 aluminium tubes?

- The same material profiles, the average length of the same unit, the weight of the high price.

- Q:How do I remove the aluminum from the PPR steady state aluminum tube?

- Hello, PPR steady pipe has a special tool called stripper. It is specially used to remove the aluminum layer on the steady pipe. I hope I can help my friend

- Q:Can aluminum pipes be used for building facades?

- Building facades can indeed utilize aluminum pipes. This material, known for its versatility and durability, is frequently employed in construction due to its lightweight composition, resistance to corrosion, and effortless installation. Aluminum pipes can be tailored to fit a range of sizes and shapes, making them ideal for various architectural designs. Moreover, aluminum can receive various coatings or finishes to enhance its aesthetic appeal and safeguard it from environmental elements. All in all, aluminum pipes are a favored option for building facades, as they provide a harmonious blend of functionality, durability, and design adaptability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum tray

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords