Embossed Sheet Metal Panel for Auto Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Embossed Sheet Metal Panel for Auto Tool Box

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Embossed Sheet Metal Panel for Auto Tool Box

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Sheet Metal Panel for Auto Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

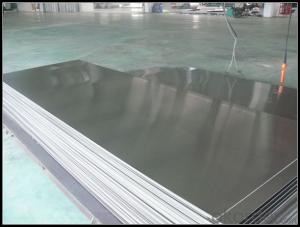

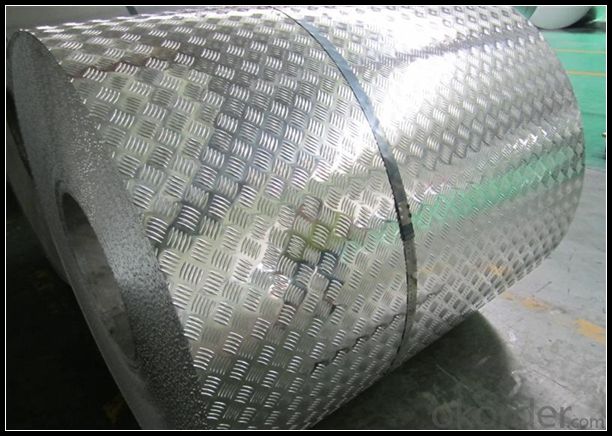

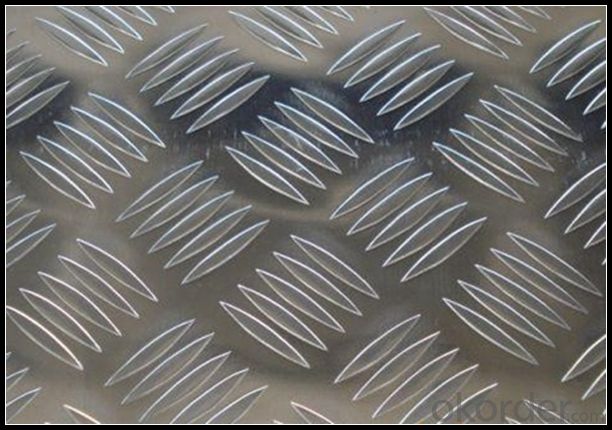

5. Image of Embossed Sheet Metal Panel for Auto Tool Box

6. Package and shipping of Embossed Sheet Metal Panel for Auto Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheets be used for heat exchangers?

- Yes, aluminum sheets can be used for heat exchangers. Aluminum is a highly efficient conductor of heat, making it an ideal material for heat exchangers. Its high thermal conductivity allows for excellent heat transfer between fluids, resulting in efficient heat exchange. Additionally, aluminum sheets are lightweight, corrosion-resistant, and have good mechanical properties, further contributing to their suitability for heat exchanger applications.

- Q:What are the different methods of surface patterning aluminum sheets?

- There are several methods of surface patterning aluminum sheets, including embossing, etching, engraving, and laser cutting. Embossing involves creating raised patterns or designs on the surface of the sheet, while etching involves chemically removing material to create patterns. Engraving is a process of cutting or carving designs into the surface, and laser cutting uses a laser beam to precisely cut or etch patterns onto the sheet. These methods offer various options for creating decorative or functional surface patterns on aluminum sheets.

- Q:What are the common thicknesses of aluminum sheets used in transportation industry?

- In the transportation industry, aluminum sheets are commonly used for various applications due to their lightweight, durability, and corrosion resistance. The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). For applications such as automotive body panels, which require a balance of weight reduction and structural integrity, aluminum sheets with thicknesses of 0.040 inches (1.02 mm) to 0.063 inches (1.6 mm) are commonly utilized. These thicknesses provide sufficient strength while keeping the weight of the vehicle lower compared to steel counterparts. In the aerospace industry, where weight reduction is of utmost importance, thinner aluminum sheets are often used. Thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are commonly employed in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is worth noting that the specific thicknesses of aluminum sheets used in the transportation industry can vary depending on the specific application, regulatory requirements, and design considerations. Therefore, it is essential to consult the relevant industry standards and specifications for precise information on the preferred thicknesses for different transportation applications.

- Q:Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q:What is the maximum temperature resistance of aluminum sheets?

- The maximum temperature resistance of aluminum sheets is typically around 600 degrees Fahrenheit (315 degrees Celsius). However, this can vary depending on various factors such as the alloy composition, thickness, and treatment of the aluminum sheets. It is always important to consult the manufacturer's specifications or obtain professional advice when considering the use of aluminum sheets in high-temperature applications.

- Q:What does aluminum plate "H12" mean?

- Such problems, it is recommended to find manufacturers, ask a clear, can not be careless, reference, Baidu encyclopedia, or 15194148663, I believe I can help you

- Q:A 15.1 g aluminum block is warmed to 53.2 °C and plunged into an insulated beakercontaining 32.6 g of water initially at 24.4 °C. The aluminum and the water are allowed to cometo thermal equilibrium.Assuming that no heat is lost, what is the final temperature of the water and aluminum?

- To solve this problem, you need the heat capacity of water and Al, I know off hand the heat capacity of water but you'll need to look it up for Al. From the problem, you know that the heat given up as the aluminum cools is gained by the water heating up. As there is no phase change, the heat gained (or lost) is mass * heat capacity * temperature change energy gained by water = energy lost by Al. Let Tf be the final temperature of the Al and water. 32.6 g * 4.18 J/gK * (Tf - 24.4C) = 15.1 g * heat capacity of Al * (53.2 C - Tf) Solve for Tf. Because there is almost twice as much water as Al and water has a higher heat capacity than Al, the temperature will be closer to 24.4C than it is to 53.2C

- Q:What are the common uses of aluminum sheets?

- Aluminum sheets have a wide range of common uses across various industries. They are often used in construction for roofing, siding, and structural components due to their lightweight and durable nature. In the transportation sector, aluminum sheets are utilized in the manufacturing of vehicles, including cars, airplanes, and boats, to reduce weight and improve fuel efficiency. Additionally, aluminum sheets are commonly used in packaging, electrical appliances, and signage due to their corrosion resistance and ability to be easily formed into different shapes.

- Q:Is aluminium plate the same as aluminium alloy?

- Oh, No. aluminum contains only aluminum, and there are some other metals besides aluminium.

- Q:Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Sheet Metal Panel for Auto Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords