Horizontal Type Boring Milling Machine With Optional Installation Turntable

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

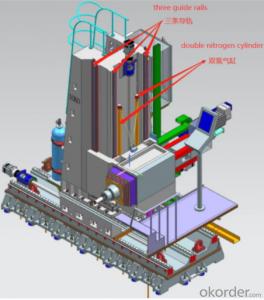

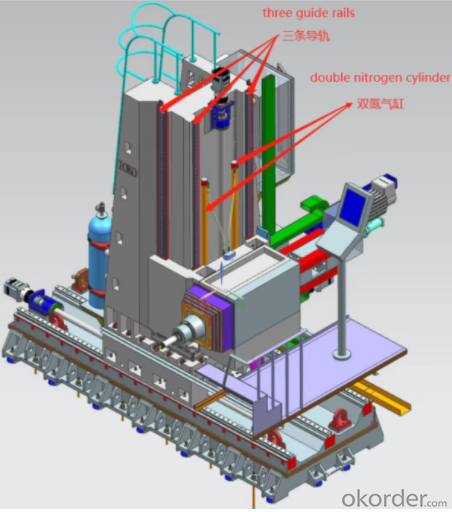

1. All main structural components are made of decaying castings, and all castings are subjected to secondary aging.

2. The spindle adopts a customized ultra strong rigid spindle, with a slider size of 420mm * 420mm, and is made of high tensile strength spherical graphite cast iron material (FCD600).

3. The column adopts polyhedral and honeycomb columns with good seismic performance, high stability, more sufficient rigidity, and less deformation.

4. Install a dual nitrogen balance cylinder to ensure more stable machine operation, higher accuracy, and faster response speed.

5. The spindle gearbox is an independent research and development product of our company. Based on actual processing conditions, it is a constant temperature gearbox that optimizes the selection of bearings, gear ratio, and modulus. It is a heavy-duty reducer with good seismic resistance, long gear life, and convenient maintenance.

6. The steel plate protective cover has been changed from the original sealing strip to a copper strip sealing to prevent high-temperature iron filings from scalding the rubber strip, improving the service life of the protective cover and ensuring the precision of the machine tool.

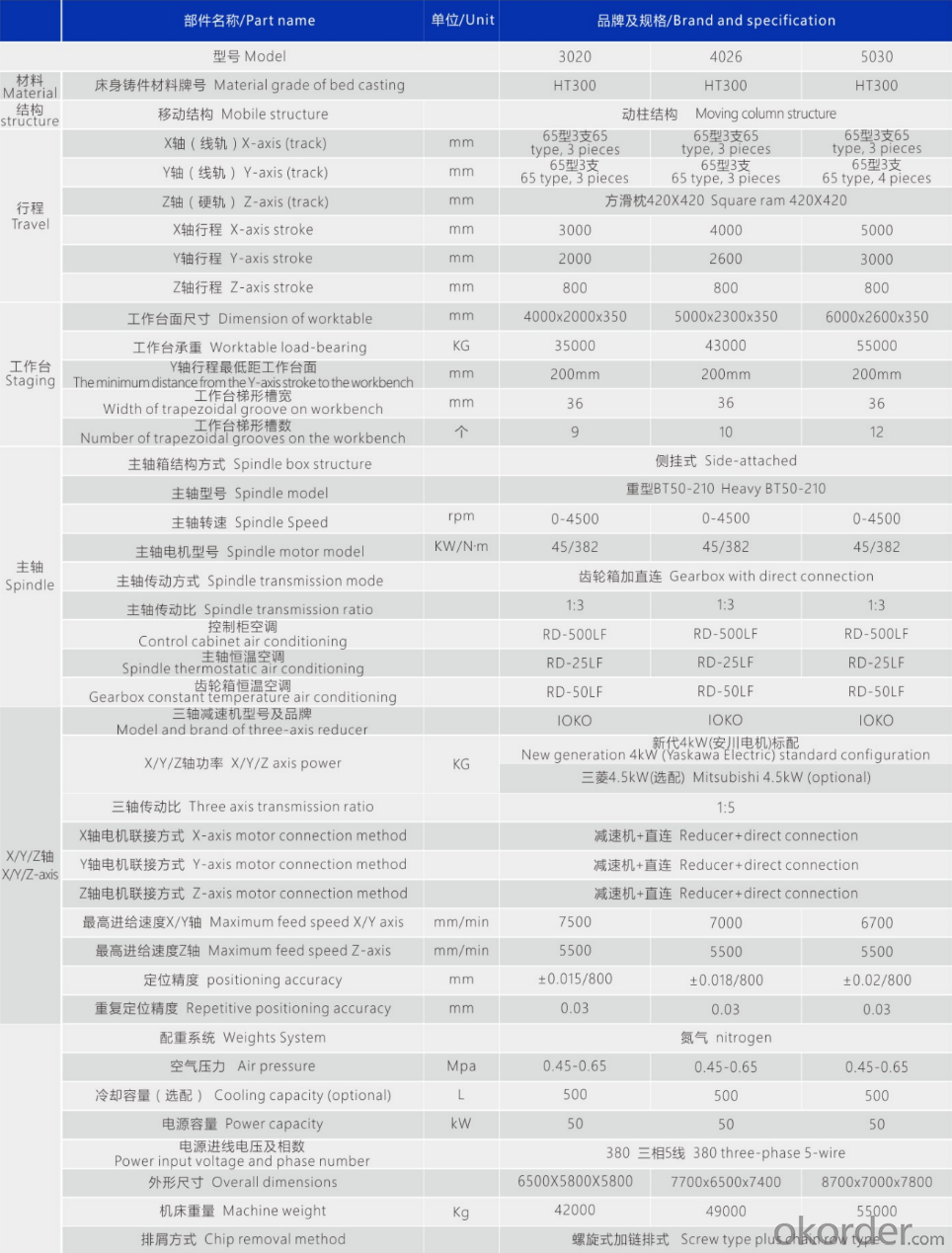

Technical Parameter

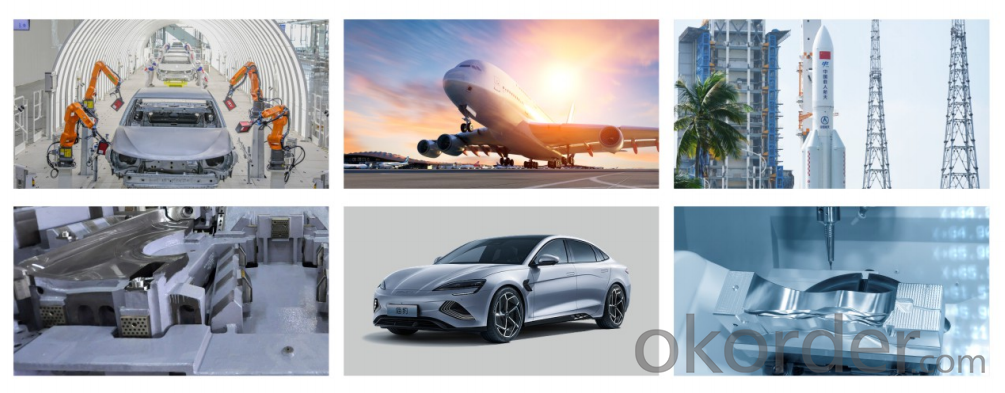

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Package

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-180 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: How do the milling machines use the electronic watch for the details?

- End angle (ED ANG): To equal the end point of the arc angle There seems to be an option is to select the clockwise drilling or counterclockwise drilling, is the 0, 1, 2 of the three figures in the two,

- Q: Manual milling machine do right angle how to do video tutorial

- ) The advantage is that the accuracy of the finish is no different from the lathe.

- Q: Causes the CNC milling machine spindle not to rotate?

- 2.1, the starting conditions may depend on the machine, the start may have been locked until the predetermined state is satisfied.

- Q: What is the difference between the lathe and the milling machine?

- The lathe is used to machine the parts of the rotor, the parts are clamped on the machine tool spindle by means of three catch chucks, and the tool is rotated at high speed, and then the tool is taken out with the turning tool.

- Q: CNC milling machine design process and abs

- (L) writing or programming before processing the workpiece should be the first processing procedures, if the workpiece processing program is relatively long and more complex, it is best not to program on the machine, and the use of programming machine or computer programming, which can avoid occupation of the machine

- Q: How is the CNC milling machine

- For the x-axis: first move the spindle to the side of the workpiece x-axis direction, with a knife gently touch the edge of the workpiece (Note that the spindle should have a knife, to turn up, but also pay attention not close too close to cut off

- Q: CNC machining Milling arcs I and J usage

- For example, the center coordinates are (0,0) The arc starting point is (10,0) then I equals 10J equals 0

- Q: What is a milling machine?

- It can process the plane, groove, can also process a variety of surfaces, gears and so on.

- Q: Where is the milling machine well?

- Ordinary milling machine has several kinds, generally divided into milling and vertical milling two, you can consider the first machine tool factory in Beijing, the domestic brand.

- Q: The use of CNC milling machine G91, meaning

- Absolute instructions, examples of incremental instructions

Send your message to us

Horizontal Type Boring Milling Machine With Optional Installation Turntable

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches