Vertical Single Stage in-line Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

Single stage in-line centrifugal pump with standard motor and mechanicak seal.

Designed to be pulled out from the top when disassemble, it can be repaired without affecting the pipelines.

Less accessible to the impurity in the liquid.

2. Application

The liquid shall be clean, thin, non-corrosive, non-flammable, and non-explosive, without any solid grain and fiber that maigh be damage the pump mechanically or chemically.

3. Technical Data

Capacity: 4~1200m3/h

Head: 20~107m

Liquid Temperature: -15~110℃

Max. Working Pressure: normal type PN12 bar, special type PN16 bar

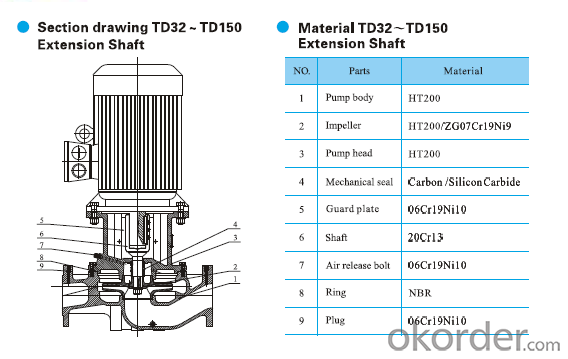

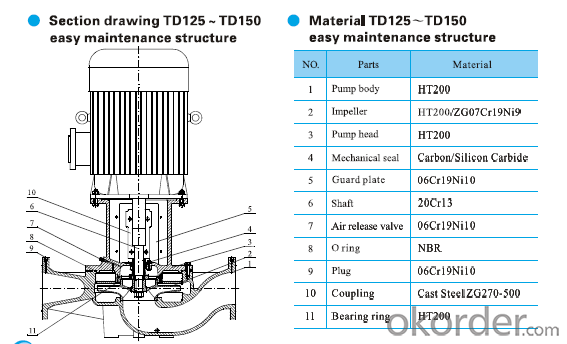

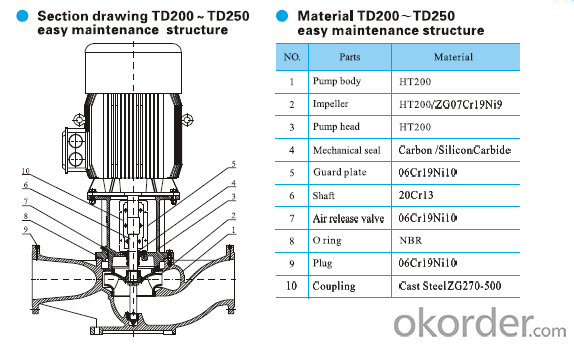

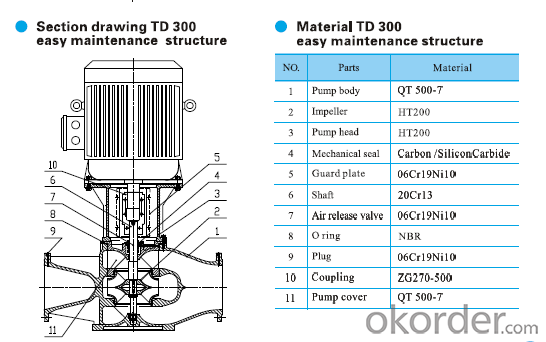

4. Pump Structure & Material

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: we changed the water pump in the car and now the horn sealtbelt light on the dash board and the speed aumator are not working what is the problem?

- You damaged the throzzle knobs.

- Q: I found a small submersible water pump for pond decorations or birdbaths in my garage. It's about the size of three decks of cards stacked on top of each other. Would there be any harm/benefit of putting this into a 55 gal fw community tank?

- No it should be no problem , but run it in the water before you put in the aquarium ..To clean out the pump..

- Q: Water is pumped upwards 4.000 m into a pool. The flow rate of the water is 4.000 L/min and it takes 10.00 minutes to fill the pool. What is the power of the pump?I would appreciate any help that you can give me - this is a question on an upcoming test!

- g = 10m/s^2 1 : Mass of water per Minute = 4 * 1000g = 4Kg Mass of water per second = 4Kg/60 Height = 4m Work per second = m(per second) g h = Power Power = 4/60*10*4 = 160/60 W = 2.6666W 2: Total Mass of water = 4 * 1000g * 10 =40Kg Height = 4m Work Done = mgh = 40*4*10 = 1600j Power = Work/Time = 1600/(10*60) = 2.6666W This is a Very Small Pump :P Hope this Helps Kaushalya Damitha

- Q: It stops and every few minutes and when it stops, it sounds like water is running.

- Ok lets go down the check list. 1) Is your cut off switch working good? Turning on and off at proper set pressure. (I don't know what you may have yours adjusted to. Mine is on at 70 off at 95.) 2) Is your expansion tank (or pressure tank) water logged? Knock on it. Does it sound full or partially full. Full is bad. You will need to shut off the water pump, close off any outgoing ports to the rest of the house, open the drain valve nearest that tank, and press your finger into the shraider valve at the top (the thing that looks like a tire stem valve). Drain the tank only. Then turn the water back on. 3) Do you have water softeners hooked up? Listen closely to the discharge tube. (this may be where it is coming from). IF you hear a leaking it is because the valve spring inside and washers need to be replaced. 4) do you have any other whole house filters? If so check the discharge tubes of them. 5) Do you have a reverse osmosis filter? IF so this is supposed to drain and you will hear it constantly. 6) Look for any water puddles 7) IF all these fail, then replace your water pump.

- Q: the pump inlet how hard is this to replace i know the timing chain cover has to be removed and is this the propable place of the leak

- If okorder has printable online manuals for most repairs but if you aren't mechanically inclined and have little experience I would advise you to take it to a mechanic and have it fixed properly. Depending on the vehicle most water pump replacement cost between 2 and 3 hundred at a garage. The timing chain cover never needs to be removed to change a water pump.

- Q: can this happen that pump is pressurizing system and no flow in suction.

- the answer is YES..but NOT from the PUMP..the type of pump most people have requires that flow through the impeller be available at all times or two things will happen !. it will cavitate (that's a gurgling sound at the pump) or 2. It will only beat the water that is in the pump and no flow will be apparent. Either one of these though could be a symptom of a plugged hot water line in the loop. Here is what happens to increase the pressure apparent.. The water on the loop is pressurized from the storage tank to the pump then out to the loop .If the loop is terminated and air gets into the end of the line next to the restriction the outside water pressure is acting like a piston compressing the air that air reacts the same as it would in any compressor and can reach higher than normal operating conditions. If you will find the plug and install an expansion bladder in the highest part of your line your flow ,pressure and noise problems will stop...Good luck with the search...From the E

- Q: A rectangular tank that is 2 feet long, 3 feet wide and 6 feet deep is filled with a heavy liquid that weighs 80 pounds per cubic foot. How much work is done pumping all of the liquid out over the top of the tank?How much work is done pumping all of the liquid out of a spout 5 feet above the top of the tank?How much work is done pumping two-thirds of the liquid out over the top of the tank?How much work is done pumping two-thirds of the liquid out of a spout 5 feet above the top of the tank?I thought that math was hard enough and now they added physics..

- Work is force x distance, which is conveniently pounds x feet. Since we are only interested in the height here (as that is the direction we are pumping), we only need to integrate along that path. The differential weight/force being pumped is the volume (LxWxH = 2 x 3 x dH) times the density (80) and the distance is the height that volume is pumped (6 - H). So W = integral( 6 * 80 * dH * (6-H)) from H=0 to 6 W = integral ((2880 - 480H) dH) = 2880H - 240*H^2 = 2880(6) - 240*(6)^2 = 8640 foot-pounds of work. If you are pumping from the spout, replace the 6-H with 11-H, and the answer becomes 23,040 foot-pounds, which makes sense since you have almost tripled the averge height you were lifting. For the 2/3, change the range of the integration to H = 2 - 6, since H = 0 - 2 represents the water at the bottom of the tank that will still be there later. This gives you answers of 3840 and 13,440 foot-pounds respectively, showing that the last couple of feet are the hardest to pump out (because they have the farthest to go...)

- Q: I have a 1999 Volkswagen Passat and the water pump seems to be leaking. The lower radiator hose has been replaced but it still leaks a fairly substantial amount. From what I can tell the pump is still doing its job but I'm losing coolant. Is there a way I can determine if i just need a new gasket or a new pump altogether without ripping the front end off? Any feedback is appreciated.

- Before you go to replace anything, you must find and repair the source of the leak. See radiator pressure test video below:

- Q: It's been slowly leaking for awhile now, but today it dumped brown water out like a bucket, when I shut it off facing up hill.

- Your best bet is to purchase a manual on OKorder and repair it yourself. Haynes repair manuals detail the correct procedures step by step and if you are handy with tools and not afraid to get your hands dirty, you can save a ton of cash by repairing things like this yourself. With the help of the manual you can probably do the job just as well as the local repair garage.

- Q: overheating.it has a new thermostat,radiator is clean.temp stays normal during idle,rises when i start to drive.ac is off when this happens.its a 4.7 dodge durango.can water pump simplyquot;go badquot;without ever leaking?

- if it,s circulating then the water pump is doing its job. does the fan kick on? maybe 1 of the hoses is closing up when your driving. usually when the bearing goes bad in the pump it takes the seal out too and starts to leak.

Send your message to us

Vertical Single Stage in-line Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords