Double Suction Split Casing Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

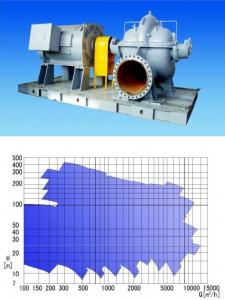

Type XS pumps are new type of single-stage double-suction centrifugal split case pumps with high performance. They are widely used in delivering liquids to the water plant, circulation water system of air conditioner, pipe net system of supplying heated water, construction, drainage pumping station, power station, power station, industrial water supply system, ship industry, mine and etc. Type XS pumps are advanced products developed from type SH, S, SA, SLA, SAP pumps. We have manufactured this type of pump with the inlet diameter 1.4m.

The technical parameter of type XS pump:

Capacity | Head | Temperature | Solid parameter | Permissible pressure | Pump outlet diameter |

22~11600m³/h

| 7~200m | -20°C~105°C(Type XS) | ≤80mg/L | ≤2.5Mpa (Type Xs) ≤4Mpa (Type XSR)

| 80~800mm |

Technical Advantage:

Type XS pumps work stably with less noise and vibration and can work at a lifting speed due to short support at both sides, thus they can be widely used.

The pipelines arrangement of type XS pump looks simple and beautiful due to inlet and outlet at a same center line.

The same rotor of type XS pumps can be operated at reverse direction to avoid damage to the pumps water hammer.

Unique design of type XS pumps working at high temperature using middle support to fasten the pump casing and using cooling seals oil lubrication bearing then pump suitable for working at 200 centigrade especially for supplying heated water to pipe net system.

Type XS pump casting parts can be vertically or horizontally mounted according to different working condition, with mechanical seals or packing seals.

Type XS pumps look beautiful with visible lines adopting industrially designing.

- Q: Home water well is artesian, to holding tank. I am needing to replace my pump yearly. Inside of the pump is rusted, this causing a real loud whining sound before failure. Pump motor isn't failing, the inside of the pump ends up freezing loosing the ability to spin.Any suggestions as to why?

- Hi I was (now retired) in the pumping industry pumps for the kind of use you appear to be using them for were normally stainess steel or stainless steel and plastic. I would suggest you look at the Xylem ( a major supplier and installer of pumps) site. Regards John

- Q: I have an 1985 cadillac fleetwood hearse and the water pump is shot to hell. where do get a good cheep one.

- There are good parts and there are cheap parts. The two never mix. Go to an autoparts store like O'reilly or Autozone. They will have what you need. ****EDIT**** An auto parts store is your cheapest option. Your only other option would be to get a used water pump, but I would not suggest putting an almost 30 year old water pump back on your car.

- Q: i have a 2000 chevy malibu (i know it sucks) i fixed the intake manifold gaskets (upper and lower) thermostat and its still leaking and sometimes overheating. my next thought is its the water pump. there's no crack in the radiator or hoses is there anything else that can cause it to overheat besides these. what about vacuum leakage? o2 sensors?

- Have the system pressure checked that will show U where the leak is.

- Q: What is the function of the backflow pipe of the fire pump?

- Generally, it is used to test the fire pump. The procedure is to start the fire pump - turn on the return pipe - return the water to the pool. The purpose of the installation is to prevent damage to the pipe caused by the excessive pressure caused by the pump.

- Q: My car broke down yesterday and is waiting to be towed to the mechanic (2000 Dodge Neon). I'm pretty sure the Timing Belt broke, but my water pump was broken in the process and leaked out lots of water. Would the timing belt break the water pump when it snapped? Or does the broken water pump lead us to a different conclusion? Any thoughts or ideas would be appreciated.Also I was reading online today about interference engines, but couldn't find a list to verify if I have one of those or not. Anyone know? Thanks!

- Timing belt replacement is a very tedious and expensive repair. It is better that when the mechanic changes your timing belt, he changes all the oil seals, timing and balance shaft belts, and the water pump. It is better to this all at once because if you only replace the timing belt, you may also have to replace the water pump in the near future, which is the same amount of labor time for the timing belt. This way all these part will have the same lifespan. If you timing belt broke, hope that your engine is not damaged.

- Q: Where can I get a solar powered water pump for a sprinker? I want the pump to pull water out of a river next to my yard and water my garden and lawn.

- you will prefer to comprehend the voltage that the pump needs and get a image voltaic panel that factors that voltage. additionally the wattage or the amperage would be a great ingredient. if the pump needs one hundred twenty volts then you definately can ignore this concept given which you will additionally choose an invertor and transformer given which you would be changing from A/C to D/C modern and additionally remodeling the voltage. a low voltage pump that in simple terms needs milliamps i heavily doubt exists. in different words this could be a damaging thought and except you prefer to spend upwards of ten grand on it then in simple terms run your self an extension twine.

- Q: i just moved into a house that has a small (about 40 gal) pond. i wanted to put fish in it. i have everything but the water pump. i've been looking around and i've found many solar fountain heads (about $30) that are pretty cheap and then i found a solar oxygenator for $100. which one would help the fish more? flowing water or just oxygen?

- Flowing water adds oxygen into the water... So Id go with that one.

- Q: What is the part called on a water pump that does the actual water moving. I want only this part to make my own water pump using a different motor and pulley.This is for lifting water 18' high and circulating through 1/2 to 3/4 inch pipe. Hoping to get about 6 gl per min

- Pump okorder /

- Q: The difference between submersible pumps and centrifugal pumps

- Submersible pump refers to the installation of pumps in the form of motor and pump body are installed underwater. It can be a sewage pump or a clean water pump or other purpose.Sewage pump to see the name will know, that is, playing sewage, you can use submersible pumps, you can also use other forms of pump.

- Q: I REPLACED MY WATER PUMP ON MY 1988 CHEROKEE,THE NEW PUMP STARTED MAKING THE SAME BEARING NOISE.

- if it is not anything else making the noise then perhaps you have a defective pump....if that jeep has a 4.0 with a manual tensioner then it is very easy to overtighten the belt and cause pre mature failure of the front bearing in the water pump

Send your message to us

Double Suction Split Casing Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords