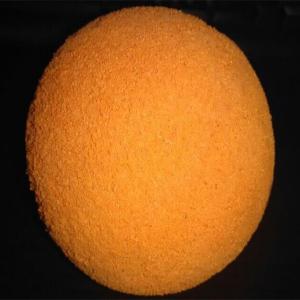

concrete pump pipeline 5'' rubber ball for pipe cleaning

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

concrete pump pipeline 5'' rubber ball for pipe cleaning

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: Is sandal rubber bottom good or polyurethane good?

- Rubber material itself poor ventilation, long wearing easily lead to beriberi. And summer rains, if the rain does not drain, will add story.

- Q: How do rubber undergo vulcanization?

- In the process of hot vulcanization, the general temperature is 10 degrees higher, and the curing time is shortened by about half. Rubber is a bad conductor of heat, which can easily cause uneven vulcanization.

- Q: What advantage does ethylene propylene rubber with three yuan compare to two yuan ethylene propylene rubber?

- Because the two EPDM molecules containing double bonds, not curing, which limits its application. In the ethylene propylene rubber commodity brand, two yuan ethylene propylene rubber accounts for only about 10% of the total. While the three rubber vulcanization available, which has been widely used, and become the main varieties of ethylene propylene rubber, ethylene propylene rubber in the commodity brands accounted for about 90%. At present, third monomers commonly used in the industrial production of three yuan ethylene propylene diene monomer are ethylene glycol norbornene (ENB), dicyclopentadiene (DCPD) and 1, 4- (HD).

- Q: How to enhance the performance of water resistant silicone rubber products

- Steam can also reduce the performance of silicone rubber / silicone products, essentially the fracture of the backbone. The hydrolysis fracture reaction becomes apparent due to the increase of temperature and the presence of ionic reagents.

- Q: How to distinguish between rubber and polyvinyl chloride?

- 1) preparation: vinyl chloride monomer (vinyl, chloride, monomer, referred to as VCM) in peroxide, azo compounds and other initiators; or under the action of light and heat, polymerization by the principle of free radical polymerization of polymers. The vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resins.2) properties: white powder, amorphous structure, degree of branching is small, the relative density of about 1.4, the glass transition temperature of 77~90 DEG, 170 DEG C to decompose, the stability of heat and light, at 100 DEG C or after long time exposure to sunlight, will decompose and produce hydrogen chloride, and further automatic catalytic decomposition that change, the physical and mechanical properties also decreased rapidly, in the practical application must be added in order to improve the stability of heat and light stabilizer of the.

- Q: How to remove the rubber front?

- The other is the freeze trimming method. Is a use of ultra low temperature makes the rubber and plastics flash rapid embrittlement of liquid nitrogen, and in this state, the flash frozen particles of high-speed jet impact products (fash), which not only can flash with high quality and high efficiency removal of rubber products (fash) and keep the special trimming equipment of all plastic products itself does not change. D shell Ba Quan?? especially in Japan, in the basic use of frozen trimming.

- Q: How is rubber made? What kind of equipment do you need? How much is it?

- Method for making rubber:A latex used in rubber plants, such as rubber trees, rubber, and grasses, for making flexible, insulating, impermeable, and air filled materials. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: What is rubber good for making weapons?

- In the event of war, import and export trade will break, how much a country has a rubber, determines the country can produce a large number of tires and other rubber products, these products will be required for the normal running of the country, when the war came, transport of various materials to manufacture materials, medical aid, in almost every kind of things all the rubber and rubber are inseparable, control, control of the war is almost

- Q: I do rubber products, I would like to ask what metal accessories are rubber products, the specific name is what, good, then points

- Silica gel tube, other rubber tube, clip fabric hose, braided hose, oil resistant hose, special hose, winding hose, industrial rubber, rubber products, insulating sleeve

- Q: There is a crack in rubber products

- The additive time temperature and pressure of semi-finished shapes semi-finished semi-finished products placed as far as possible when placed speed gap semi-finished size can be more appropriate to put five percent to ten percent semi finished mixing can put some help curing

Send your message to us

concrete pump pipeline 5'' rubber ball for pipe cleaning

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords