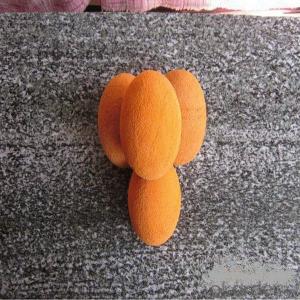

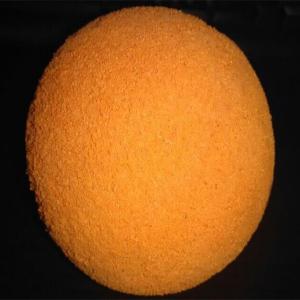

pipe fitting 125mm soft cleaning rubber ball for sany pump

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

pipe fitting 125mm soft cleaning rubber ball for sany pump

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: Rubber and metal have to be sealed before they are too strong

- Different materials and O-ring O-ring compression the change of general material such as NBR, NR, nitrile rubber, natural rubber, chloroprene rubber CR, EPDM three EPDM, HNBR hydrogenated nitrile rubber, silica gel SILICOME SBR Buna, styrene butadiene rubber, SBR, acrylate rubber ACM, compression O-ring or the 20% to calculate. If it is a special material FKM, VITON, PU, FLS silicon fluorine rubber, fluorine rubber, polyurethane, compression of these materials is calculated by 15% o ring.

- Q: What gum does rubber and metal stick together?

- The cohesion of JL-518 silicone rubber heat vulcanization glue: is a new high performance silicone primer. For the bonding of silicone rubber, TPU and aluminum, iron, copper, stainless steel and other metal nylon cloth special adhesive, in particular for the preparation of silicone rubber rollers and composite rubber products, its performance is better than other similar products, the role of shear bonding surface can withstand long time twist extrusion stress. The preparation of ordinary rubber rolls and compound rubber products such as ethylene propylene rubber also has good effect. Non-toxic, no harmful solvents, comply with environmental protection requirements, no adverse effects on human health.

- Q: How do rubber undergo vulcanization?

- In the process of hot vulcanization, the general temperature is 10 degrees higher, and the curing time is shortened by about half. Rubber is a bad conductor of heat, which can easily cause uneven vulcanization.

- Q: What kind of rubber products are expensive?

- Other technologies, processes, and logistics all determine the cost

- Q: What is the difference between vulcanized rubber and butyl rubber?

- Nitrile butadiene rubber is prepared by polymerization of butadiene and acrylonitrile by emulsion polymerization. Nitrile rubber is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesive force. Its disadvantage is poor resistance to low temperature, poor ozone resistance

- Q: What is the definition of mixed rubber?

- Mixed rubber, also called synthetic rubber, is a synthetic, highly resilient polymer. Also known as synthetic elastomer, is one of the three major synthetic materials, its yield is only lower than synthetic resins (or plastics), synthetic fiber.

- Q: What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- Plastic and rubber are high molecular material, mainly composed of two kinds of carbon and hydrogen atoms, and some contain a small amount of oxygen, nitrogen, chlorine, fluorine, silicon, sulfur atoms, its special properties, use is also special. At room temperature, the plastic is not solid, hard, and tensile deformation of rubber hardness is not high., elastic, can be stretched, and stop pulling back to normal. This is due to differences in their molecular structure. Another difference is the plastic can be repeatedly recycled, while the rubber cannot be directly recycled, can only be processed and then reclaimed rubber, plastic and rubber. Available in the form of more than 100 to 200 degrees at 60 to 100 degrees. The morphological similarity does not include plastic rubber.

- Q: What is food grade natural rubber?

- Standard rubber, natural rubber latex concentrate only and solid and liquid substances is concentrated latex by high-speed centrifuge after processing, required special barrel plus fresh, dry rubber content is 60%; the standard is a standard solid rubber rubber good solidification, machining, drying, packaging, which according to the impurity content to several levels and it has international standards, countries also have the corresponding standard.

- Q: What about the smell of smoked rubber products?

- Rubber deodorant both rubber itself, also want to consider a variety of additives such as odor curing agents released, in addition to the use of rubber ingredients to improve rubber products and improve the level of environmental protection, rubber production environment, is of great help for the comprehensive utilization of recycled rubber resources. A form of powder or liquid used in rubber, usually based on odor and odor characteristics.

- Q: Is there any poison in the processing and testing of rubber products? What about the salary?

- There will be some flavor at the time of processing, as well as some fillers, oil will be a little toxic, and some crosslinking agents may be toxic. But now the mixer extruder is mostly closed, so it is common to pay attention to respiratory protection.A mechanical test is usually less toxic, and a glove is enough.If you do thermal testing, such as TGA, DMA, DSC and so on, it will degrade and release small molecules, especially if the aromatic oil is filled, be sure to pay attention to.

Send your message to us

pipe fitting 125mm soft cleaning rubber ball for sany pump

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords