Small Bore Plastic Pipe

Small Bore Plastic Pipe Related Searches

Small Bore Plastic Tubing Small Plastic Tubes Small Plastic Storage Tubes Small Diameter Rigid Plastic Tubing Small Plastic Tubes With Lids Rectangular Plastic Pipe Clear Plastic Pvc Pipe Large Diameter Clear Plastic Pipe Plastic Tubing Structure Pipe Curved Plastic Tubing Plastic Tube With Cap Rectangular Plastic Tubing Plastic Poster Tube Plastic Coin Tubes Black Rubber Hose Pipe 1 Stainless Steel Pipe Boom Pipes Stainless Steel Flue Pipe 4 Stainless Steel Pipe Plastic Storage Tubes With Caps Clear Plastic Shipping Tubes 1 2 Stainless Steel Pipe Plastic Cigar Tubes Stainless Steel Screen Pipe Plastic Tube Slide Plastic Cores Tubes Stainless Steel Pipes Colored Polypropylene Tubing 1 Inch Stainless Steel PipeSmall Bore Plastic Pipe Supplier & Manufacturer from China

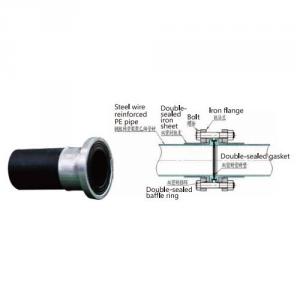

Small Bore Plastic Pipe is a versatile type of tubing made from various types of plastic materials, such as PVC, PE, and PP. These pipes are known for their durability, flexibility, and resistance to corrosion, making them ideal for a wide range of applications. They are commonly used in plumbing, irrigation systems, and for transporting water and other fluids in both residential and commercial settings. Due to their lightweight nature and ease of installation, small bore plastic pipes have become a popular choice for many industries and construction projects.Small Bore Plastic Pipe finds its application in various scenarios, such as in the construction of buildings, agriculture, and industrial facilities. They are particularly useful in situations where a high level of flexibility and durability is required, such as in the installation of underground water supply systems or in the transportation of chemicals and other hazardous materials. The pipes are also favored for their ability to withstand extreme temperatures and pressures, making them suitable for both hot and cold water applications. Furthermore, their resistance to corrosion and chemical damage ensures a long service life and reduces the need for frequent maintenance or replacement.

Okorder.com is a leading wholesale supplier of Small Bore Plastic Pipe, offering a vast inventory of high-quality products to cater to the needs of various industries. With a commitment to providing top-notch customer service and competitive pricing, Okorder.com has established itself as a reliable source for businesses looking to purchase these pipes in bulk. Their extensive range of products ensures that customers can find the exact type of small bore plastic pipe they need, whether it's for a specific project or for general use in their operations. By partnering with Okorder.com, businesses can benefit from a streamlined procurement process and access to a wide variety of products, all while enjoying the convenience of online shopping.

Hot Products