Fittings Plastic Pipes PPR Pipes & Fittings from China Supplier & Manufacturer

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPR Pipes & Fittings Characteristics and Benefits:

1.Green, environmental protection, sanitation non-toxic, health indicators in line with national drinking water requirements.

2.Good stability, resistance to high temperature and pressure.

3.Excellent anti-aging properties, service life over 50 years under the German standards DIN8077/8078

4.A hot melt homogeneity connect to eliminate hidden dangers of leakage

5.Meeting all health requirements, no corrosion and/or encrustation

6.Exceptionally long service life while preserving high utility value

7.Trouble-free operations with less noise

8.Quick, easy and clean installation works

9.Resistance in aggressive environments(e.g.in agricultural applications)

PPR Pipes & Fittings Color:

Grey, White, Green

PPR Pipes & Fittings International Standards:

DIN8077/8078、GB/T18742.2-2002

PPR Pipes & Fittings International Certificates:

ISO9001, ISO14001, WRAS, GOST, SABS, CE

PPR Pipes & Fittings Environmental Aspects:

Fully recyclable product; neither toxic nor otherwise harmful substances are used in its manufacture and/or application

PPR Pipes & Fittings Intended Use:

1.Distribution for cool and hot water

2.Pipes for kinds of high-temperature and low-temperature heating system.

3.Pipes for heating and colling settings in solar energu system

4.Connecting pipe for air-conditions

PPR Pipes & Fittings Technical Specifications:

Material-statistical polypropylene copolymer(random-copolymer)for injection moulding and extrusion processes with excellent welding ability;nickel-plated brass fittings.

Manufacturing process-pipes are produced by extrusion, while fittings by injection moulding

Shapes-pipe lengths or coils

Assembly/fixing-the product range covers all needs for interior water distribution systems and heating system routes

Transitions for other pipe materials-implemented by threaded connections(i.e.by combined couplings)or flange connections

Coupling-standard method is poly fusion welding or by electro fitting

Surface finish-elements are in white and green colour without any finish, separate metal elements-brass, alternatively nickel plated, black identification printing on the surface

PPR Pipes & Fittings Physic-chemical Properties:

1.Specific weight-0.9kg/m3

2.Thermal expansion coefficient-for PPR pipes 0.12mm/mK

3.Thermal conductivity 0.22W/mK, fire rating-Class C3

4.Resistance against chemicals-PPR piping systems are intended mainly for water distribution(drinking, cold, hot, irrigation and etc.)-it is also possible to use the system for other media, in which case their concrete use is governed by DIN8078 Bb1-possible to consult the manufacturer

Different Nominal Pressure, Different Application:

1.PN10-cold water distribution and floor heating systems

2.PN12.5-cold water distribution and floor heating systems

3.PN16-higher pressure cold water distribution and DHW systems at lower pressures

4.PN20-hot water distribution systems, central heating

5.20mm/25mm/32mm/40mm/50mm/63mm/75mm/90mm/110mm/125mm/140mm/160mm/200mm

Nominal Pressure and Sizing:

PN20

20mm/25mm/32mm/40mm/50mm/63mm/75mm/90mm/110mm/125mm/140mm/160mm

PPR-AL-PPR equal-thickness wall composite pipe:

Description:

1.PPR-AL-PPR aluminum plastic composite pipe is consisted of five layers.

2.The middle layer is thin aluminum, outer layer is PPR, inner layer is PPR.

3.There is imported heat glue which is extruded by high temperature and high pressure.

Features:

1.Five-storey structure combines the rigid metal pipe and health and sealing plastic pipe perfectly.

2.The middle layer of aluminum isolates the external air, infiltrating the external oxygen barrier pipe,inhibiting the bacterial survival in the breeding pipeline.It is used to ensure the health of the water in the pipe and to prevent secondary pollution invisible.

3.The expansion properties of PPR-AL-PPR pipe is close to metallic materials, and has no apparent"expansion in hot and reduction in cold" when install and apply to use, the outside is more straight and arractive.

Advantages:

1.Greatly reduced linear expansion coefficient, only 1/4 of that of PPR

2.100% oxygen tightness, suitable for heating system.

3.Improved resistant to impulse under low temperature, resistant to UV-rays.

4.Easily detected by detector when embedded, owing to the metal layer.

Nominal Pressure and Sizing:

PN25, 20mm/25mm/32mm/40mm/50mm/63mm

FR-PPR Fibreglass high-powered composite pipe

Description:

1.FR-PPR Fibreglass high-powered composite pipe is consisted of three layers.

2.The middle layer adopts imported fibreglass strengthen material, the inner and the outer layer is PPR.

Features:

1.FR-PPR pipe has higher strength, higher tenacity and lower linear expansion coefficient.

2.Non-deformation pipeline,more attractive appearance.

3.Resist high temperature,leak explosion-proof pipe.

Advantages:

1.1/3 lower coefficient of thermalexpansion than common PPR pipe

2.Thin,light,20% flow capacity addition

3.More compression resistance,longer service life

4.Outdoor installation, widely applied fields

5.Completely use imported raw material, ensure product quality

Nominal Pressure and Sizing:

PN20/PN25, 20mm/25mm/32mm/40mm/50mm/63mm

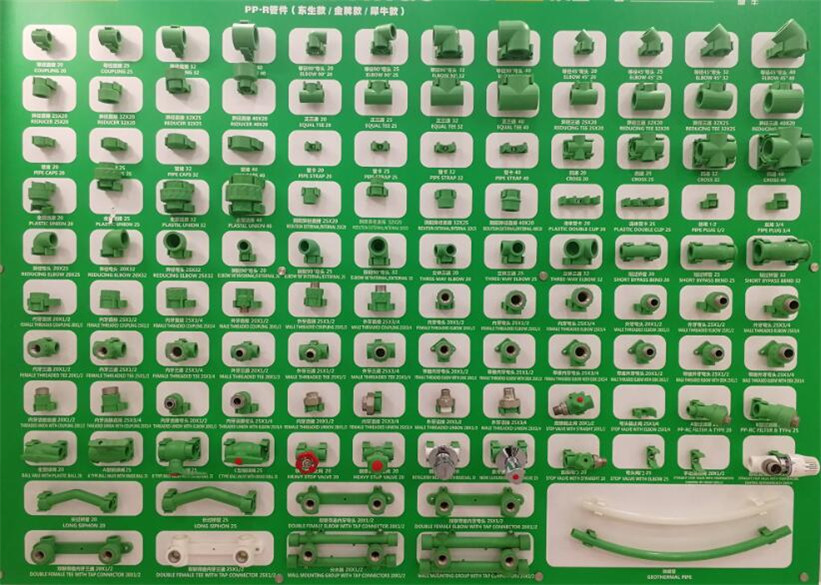

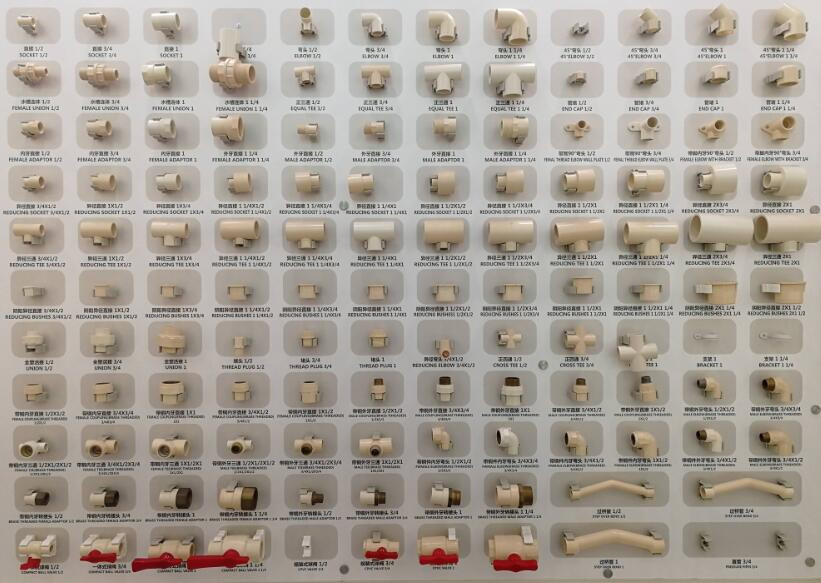

All different kinds of Fittings we are supplying

Plastic fittings

1.Coupling

2.Equal Tee

3.Elbow 45°

4.Elbow 90°

5.Pipe Caps

6.Reducing Elbow

7.Cross

8.Plastic Union

9.Long siphon

10.Short bypass bend

11.Long bypass bend

12.Flange set

13.Reducer

14.Reducing tee

15.Pipe plug

16.Long pipe plug

17.Three-way elbow

18.Elbow 45° internal/external

19.Elbow 45° internal/external

20.Plastic clip

21.Plastic double clip

Brass fittings

1.Female threaded coupling

2.Male threaded coupling

3.Female threaded elbow

4.Male threaded elbow

5.Female threaded tee

6.Male threaded tee

7.Female threaded union

8.Male threaded union

9.Socket brass union

10.Male threaded elbow with disk

11.Female threaded elbow with disk

12.Reducing sleeve with metal male thread"dGK"with cross

13.Tee with tap connector male

14.Tee with tap connector female

15.Elbow 90° for wall mounting male

16.Elbow 90° for wall mounting female

15.Elbow 90° for wall mounting internal/external male

16.Elbow 90° for wall mounting internal/external female

17.Elbow 90°for gypsumwall mounting

18.Wall mounting group with tap connectors

19.Double female elbow with tap connector

20.Double male elbow with tap connector

21.Double female tee with tap connector

22.Double male tee with tap connector

PPR Fitting FAQ

1.What is your MOQ?

Our MOQ is usually 5 CTNS.

2.What is your delievery time?

The time of delievery is around 30 days.

3.What is your payment terms?

We accept 30% T/T in advance,70% in the period of shipment or 100% L/C.

4.What is the shipping port?

We ship the goods to Ningbo or Shanghai port.

5.What is the address of your company?

Our company locates in Beijing while our production base locates in Ningbo

6.How about the samples?

Generally, we could send you the samples for free, however you need to pay the courier fee.

- Q: Are plastic pipe fittings suitable for industrial cooling towers?

- Yes, plastic pipe fittings are suitable for industrial cooling towers. They provide excellent corrosion resistance, durability, and cost-effectiveness, making them a popular choice in cooling tower applications. Additionally, plastic pipe fittings offer easy installation and maintenance, making them a practical solution for industrial cooling systems.

- Q: Are plastic pipe fittings resistant to scaling and buildup?

- Yes, plastic pipe fittings are generally resistant to scaling and buildup.

- Q: Can plastic pipe fittings be used in irrigation systems?

- Yes, plastic pipe fittings can be used in irrigation systems. They are commonly used due to their durability, cost-effectiveness, and resistance to corrosion. Additionally, plastic fittings are easy to install and require minimal maintenance.

- Q: Are plastic pipe fittings resistant to electrical conductivity?

- Yes, plastic pipe fittings are generally resistant to electrical conductivity.

- Q: How do you remove plastic pipe fittings?

- To remove plastic pipe fittings, start by turning off the water supply and relieving any remaining pressure in the pipes. Then, use a wrench or pliers to loosen the fittings by turning them counterclockwise. If the fittings are stubborn, applying heat with a hairdryer can make the plastic more pliable and easier to remove. Alternatively, you can cut the pipe just above the fitting and use a new fitting for replacement.

- Q: Do plastic pipe fittings require any special reinforcement or clamping?

- Yes, plastic pipe fittings often require special reinforcement or clamping. This is necessary to ensure a secure and leak-free connection between the pipes. Reinforcement methods may include using pipe clamps, inserts, or adhesive tapes to provide additional support and strength to the fittings. It is important to follow the manufacturer's instructions and guidelines for proper reinforcement and clamping techniques to ensure the integrity and reliability of the plastic pipe system.

- Q: How can the leakage between the solar heating pipe and the water tank joint be avoided?

- If the glue is used, the place is leaking, so it's better to cut the leak with the pipe scissors and replace it with a new one

- Q: Are plastic pipe fittings suitable for hot water systems?

- Yes, plastic pipe fittings are suitable for hot water systems. They are commonly used in plumbing applications and can withstand the high temperatures and pressures associated with hot water.

- Q: Can plastic pipe fittings be used in renewable energy systems?

- Yes, plastic pipe fittings can be used in renewable energy systems. Plastic pipe fittings offer various benefits such as corrosion resistance, lightweight design, and ease of installation. They are commonly used in solar thermal systems, geothermal systems, and other renewable energy applications where durability and longevity are essential.

- Q: How do plastic pipe fittings compare to metal fittings?

- Plastic pipe fittings are generally lighter, more cost-effective, and easier to install compared to metal fittings. They are resistant to corrosion and chemical damage, making them suitable for various applications. However, metal fittings are generally stronger and more durable, offering greater longevity and withstanding higher pressures. The choice between plastic and metal fittings depends on specific needs, such as the type of pipe, application, budget, and desired lifespan.

Send your message to us

Fittings Plastic Pipes PPR Pipes & Fittings from China Supplier & Manufacturer

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords