Raktherm Ppr Pipes

Raktherm Ppr Pipes Related Searches

Kalde Ppr Pipes Pilsa Ppr Pipes Belden Ppr Pipes Borplus Ppr Pipes Dizayn Ppr Pipes Novatherm Ppr Cosmoplast Ppr Pipes Ppr Pipe Jointing Method Ppr Meaning Pipes Gf Ppr Pipe ppr pipes specifications Supreme Ppr Pipes Catalogue Rectangular Plastic Pipe Ppr R ppr pipes price list philippines ppr pipe sizes in mm and inches ppr pipes manufacturers in europe ppr pipes manufacturers in india ppr pipe price philippines Rfp Pipe Georg Fischer Ppr Pipes Catalogue Clear Plastic Pvc Pipe ppr pipes and fittings price list Perforated Pvc Pipe polypropylene pipe specifications Amiantit Grp Pipes Rectangular Plastic Tubing Polypropylene Pipe Size Chart ppr pipe manufacturers in saudi arabia Dip TubesRaktherm Ppr Pipes Supplier & Manufacturer from China

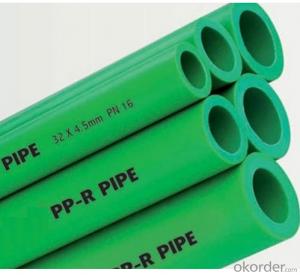

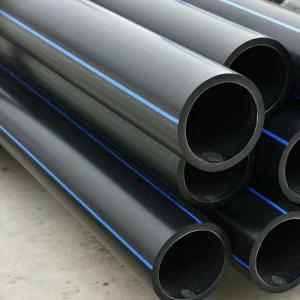

Raktherm PPR pipes are a popular choice in the plumbing industry due to their durability, corrosion resistance, and ease of installation. These pipes are made from polypropylene random copolymer, a material known for its high strength and flexibility. They are widely used in various applications such as potable water supply systems, heating and cooling systems, and irrigation networks.Raktherm PPR pipes are highly regarded for their ability to withstand high pressure and temperature fluctuations, making them suitable for a range of demanding environments. They are also praised for their resistance to chemicals and microorganisms, ensuring the safety and purity of the fluids they transport. This makes them an ideal choice for residential, commercial, and industrial applications where reliability and performance are paramount.

Okorder.com is a leading wholesale supplier of Raktherm PPR pipes, boasting a vast inventory to cater to the diverse needs of clients worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Raktherm PPR pipes they supply meet the highest industry standards. This makes them a trusted source for those seeking reliable and high-performing plumbing solutions.

Hot Products