38mm Plastic Pipe Fittings - Double Sealed Super Connection for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

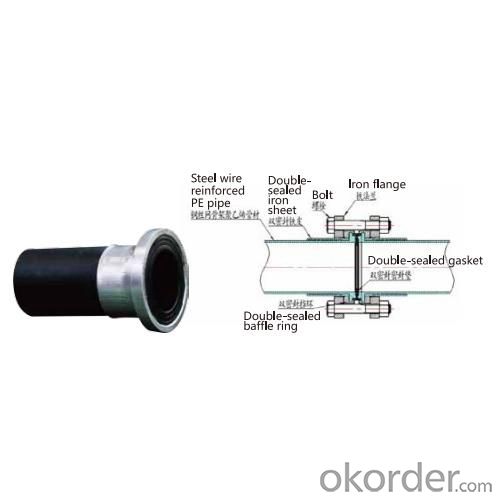

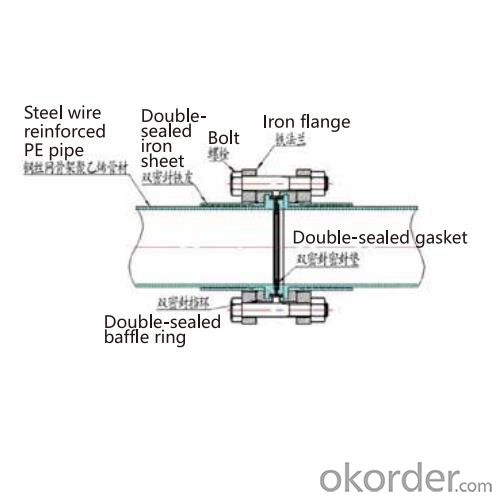

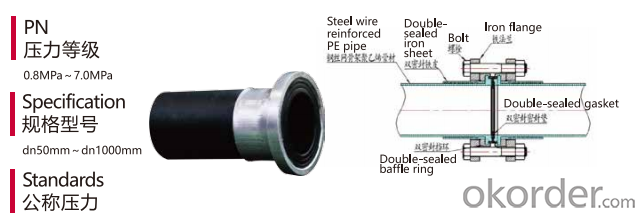

Double Sealed Super Connection for Pipeline System

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Can plastic pipe fittings withstand high temperatures?

- Yes, plastic pipe fittings can generally withstand high temperatures. However, the specific temperature limits may vary depending on the type of plastic used for the fittings. It is important to consult the manufacturer's guidelines and specifications to ensure the fittings are suitable for the intended temperature range.

- Q: How do you connect plastic pipe fittings to PEX pipes?

- To connect plastic pipe fittings to PEX pipes, you can use push-fit or compression fittings specifically designed for PEX. Push-fit fittings require no tools and are simply inserted into the PEX pipe until they click in place. Compression fittings, on the other hand, involve tightening the nut over the fitting onto the PEX pipe with a wrench to create a secure connection.

- Q: Are plastic pipe fittings resistant to abrasion?

- Yes, plastic pipe fittings are generally resistant to abrasion.

- Q: What are the common jointing methods for plastic pipe fittings?

- The common jointing methods for plastic pipe fittings include solvent welding, mechanical compression, threaded connections, and push-fit connections.

- Q: Do plastic pipe fittings require any special reinforcement or clamping?

- Yes, plastic pipe fittings often require special reinforcement or clamping. This is necessary to ensure a secure and leak-free connection between the pipes. Reinforcement methods may include using pipe clamps, inserts, or adhesive tapes to provide additional support and strength to the fittings. It is important to follow the manufacturer's instructions and guidelines for proper reinforcement and clamping techniques to ensure the integrity and reliability of the plastic pipe system.

- Q: Can plastic pipe fittings be used for high-pressure systems?

- No, plastic pipe fittings are not suitable for high-pressure systems as they are generally designed for low to moderate pressure applications.

- Q: Can plastic pipe fittings be used for cooling towers?

- Yes, plastic pipe fittings can be used for cooling towers. Plastic fittings are commonly used in cooling tower systems due to their resistance to corrosion and ability to withstand the harsh conditions of cooling tower environments. They offer several advantages such as lightweight, easy installation, and cost-effectiveness. However, the specific type of plastic material used should be chosen based on the temperature and chemical requirements of the cooling tower system.

- Q: What are the common maintenance requirements for plastic pipe fittings?

- Common maintenance requirements for plastic pipe fittings include regular inspection for any signs of wear, cracks, or leaks. It is important to ensure that fittings are properly tightened and secured, and any loose or damaged fittings should be replaced immediately. Regular cleaning and removal of any debris or blockages is also necessary to maintain optimal performance. Additionally, it is important to avoid exposing plastic pipe fittings to extreme temperatures or chemicals that may cause damage.

- Q: Are plastic pipe fittings suitable for food processing industries?

- Yes, plastic pipe fittings are suitable for food processing industries. They are resistant to corrosion, easy to clean, and provide a hygienic solution for transporting food materials. Additionally, plastic pipe fittings are lightweight, cost-effective, and offer flexibility in installation.

- Q: Can plastic pipe fittings be used for swimming pool filtration?

- Yes, plastic pipe fittings can be used for swimming pool filtration. Plastic pipe fittings are commonly used in swimming pool systems as they are durable, resistant to corrosion and chemicals, and can easily handle the water pressure necessary for filtration.

Send your message to us

38mm Plastic Pipe Fittings - Double Sealed Super Connection for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords