High Quality Food Grade PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Food Grade PVC Conveyor Belt

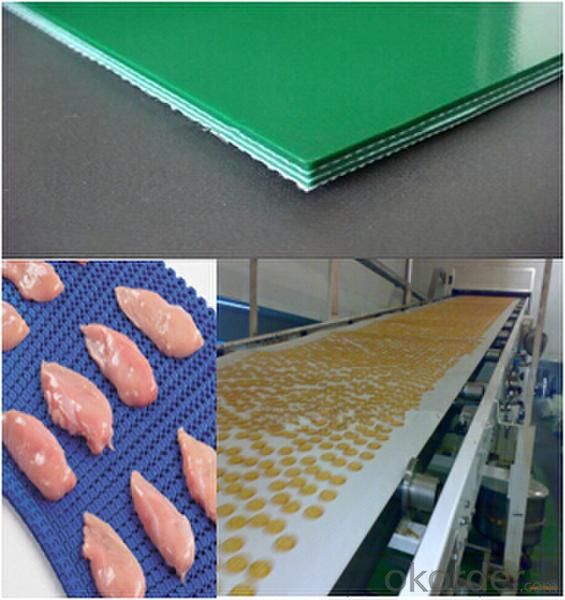

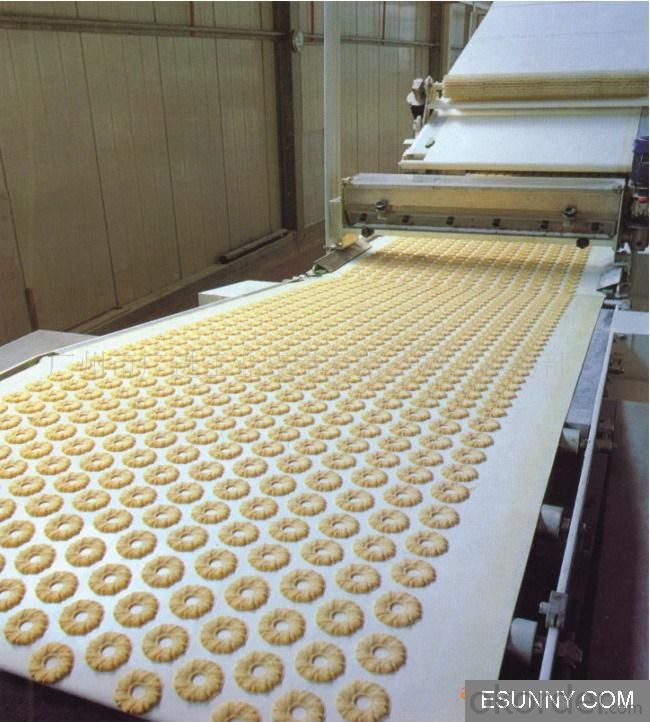

The proporties of PVC conveyor belt:

PVC type conveyer belt's upper and lower layers are PVC coating cover, single-sided tape thickness: ≥1.0mm; PVG type belt's upper and lower layers are nitrile rubber and PVC, single-sided tape thickness: 1.5mm-4.5mm.

PVC type conveyer belt's inclined angle: <16°

PVG conveyer belt's inclined angle: <20°

Specifications of PVC food conveyor belt:

1.width: 300mm-1800mm

2.thickness:4mm-30mm

3.number of piles:1-6 ply

4.tensile strength:8Mpa-20Mpa

Configuration:

Flame retardant conveyer belt is made from the whole belt core via dipping and plastifying in polyvinyl chloride (PVC) dipping agent or sulfuration. It features largely in the high strength, large freight volume and stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant

Technical standards: MT914-2008, BS3289, BC158, AS4606, etc

Pls contact me freely if any inquiry or questions,thank you!

- Q:How to test the abrasion resistance of rubber?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q:What kind of rubber is suitable for waterproof aprons?

- One to do waterproof rubber ring, choose ethylene propylene rubber! The main sealing ring of fire ditch pipe is mainly made of ethylene propylene rubber!! Physical and chemical properties have corresponding national standards!

- Q:How are rubber wires processed?

- In the production of rubber products, vulcanization is the last process.Vulcanization is a crosslinking process in which rubber molecules change from linear structure to network structure under certain conditions. Curing methods are cold vulcanization, room temperature vulcanization and heat vulcanizing three kinds. Most rubber products are vulcanized by heat. Hot vulcanizing equipment, vulcanizing pot, flat vulcanizing machine, etc.. Rubber wires and cables are vulcanized by continuous hot air.

- Q:Why do rubber products Blister?

- Foaming reasons of rubber products:1 vulcanization is not sufficient, the temperature is too low or time is too short, so that the volatile compounds produced during curing have not been cleaned out;2, the vulcanizing pressure is insufficient, the detained gas and sulfur volatile matter can not be discharged in time.3, there is air or moisture in the glue;4, curing temperature is too high, the surface of the gum material premature vulcanization, hindered the rubber material in the steam, air free precipitation.

- Q:What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The electric property of natural rubber is a kind of non polar material, and it is a better insulating material. When the natural rubber vulcanization after the introduction of polarity factors, such as sulfur, accelerator, so that insulation performance.

- Q:Can rubber products be injection molded and plastic injection functions?

- Rubber products can be injection molding, plastic injection function.

- Q:What's wrong with rubber whitening?

- Rubber whitening (spray cream) the main reason for analysis, rubber spray cream, including rubber surface spray and surface spray cream. Spray (Bloom) is a phenomenon in which liquid or solid agents migrate from rubber to rubber surfaces [1]. It can be seen that the inner compound of rubber will precipitate and form a spray. There are three kinds of forms of rubber spray. Powder spraying, wax injection, injection (also known as exudation).1. powder is a curing agent, accelerator, activator, antioxidant and filler powder with precipitation agent on the rubber surface, and form a layer of powder.2. spray wax is paraffin wax, ceresin wax precipitation etc. on the rubber surface, forming a layer of wax.3. fuel injection is softening agent, tackifier, lubricants, plasticizers and other additives in liquid precipitation of the rubber surface, and form a layer of oil.In practice, frost forms on rubber surfaces sometimes appear in one form, sometimes in two or three forms.

- Q:What is the role of softening plasticizers in rubber? How are they classified?

- A rubber plasticizer is a reagent. Rubber plasticizer refers to add certain substances in rubber, can make the force rubber molecules is reduced, thereby reducing the glass transition temperature of the rubber, the rubber plasticity and fluidity, easy calendering and extrusion molding operation, but also can improve the mechanical properties of the vulcanizate of some physical machines, such as the decrease of hardness and elastic constant tensile stress, with high and low heat, improve the cold tolerance.

- Q:What kinds of vulcanized rubber do you have?

- According to the properties and uses of rubber: in addition to natural rubber, synthetic rubber can be divided into general synthetic rubber, semi general synthetic rubber, special synthetic rubber and special synthetic rubber.

- Q:Advantages and disadvantages of rubber products

- Natural rubber NR(Natural Rubber) rubber made by collecting latex, is isoprene polymer. With abrasion resistance, high elasticity, tensile strength and elongation as well. Aging in the air, hot sticky, easy expansion in mineral oil or gasoline and dissolved, but not resistant to strong acid and alkali. Advantages: good elasticity, acid and alkali. Disadvantages: not weather, not oil resistant (resistant vegetable oil) is the production of adhesive tape, rubber hose, rubber material, and is suitable for the production of damping parts, brake products using oil and ethanol in the liquid with hydroxyl in the car.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

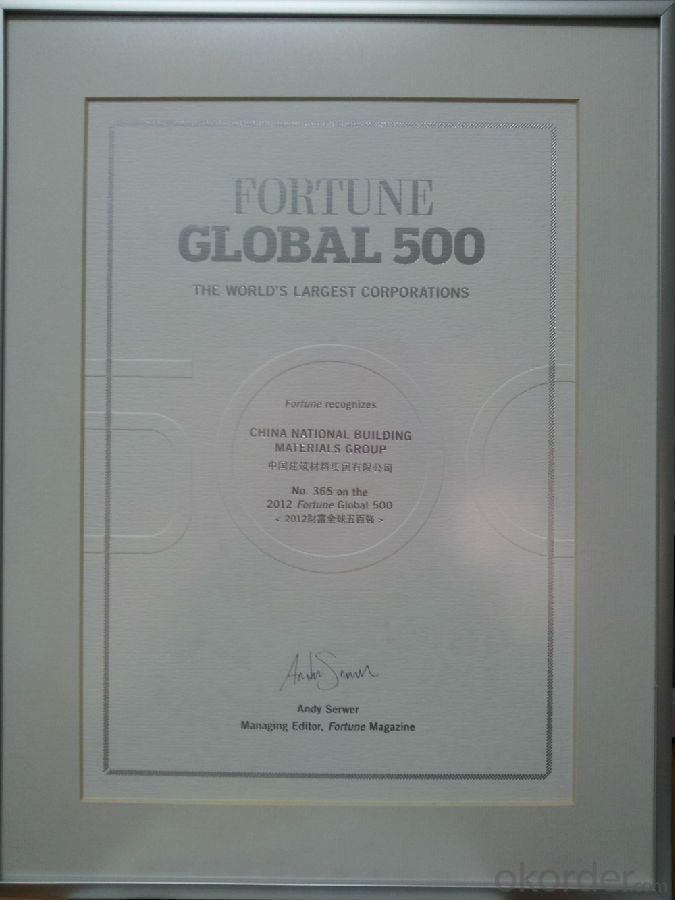

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Food Grade PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords