PVC Conveyor Belt with Skirt Sidewall Raised Edge Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt with Skirt Sidewall Raised Edge Conveyor Belt

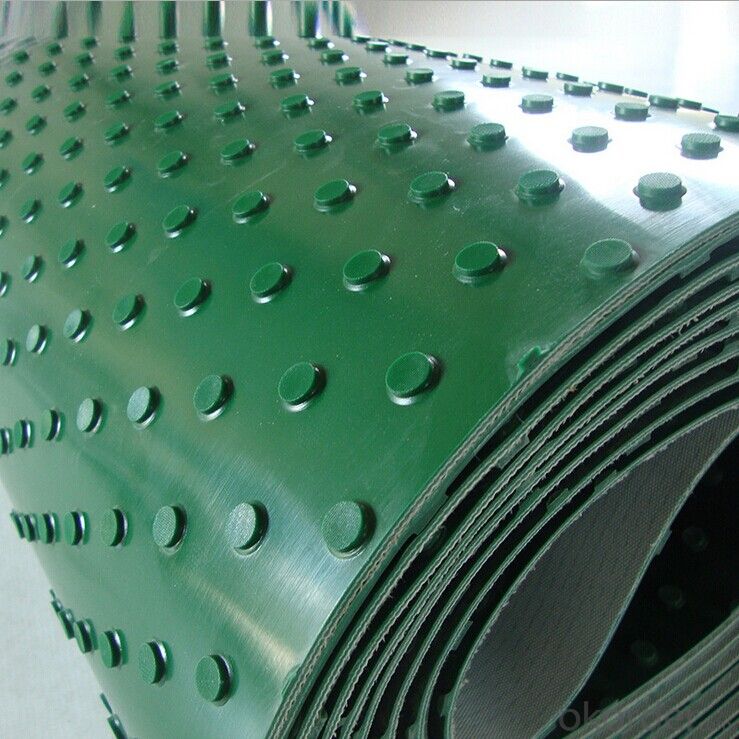

Descriptions of Sidewall PVC Conveyor Belt

Conveyor belt is the major part of conveyor,it is widely used in metallurgy,building,electric power,wharf,mining and other industries.

Advantages of Sidewall PVC Conveyor Belt

1. Low maintenance cost.

2. Large conveyor capacity and it can effectively avoid materials from spilling.

3. Convey materials from the horizontal to the inclined or vice verca freely.

4. It saves large space as it allows materials to be conveyed at any angels from 0-90 degrees.

Applications of Sidewall PVC Conveyor Belt

It is widely used in port, harbors,metallurgic industry,mining,electrc power plants,coal industry,foundries, architecture,grain industry,cement industry,fertilizer industry,etc.

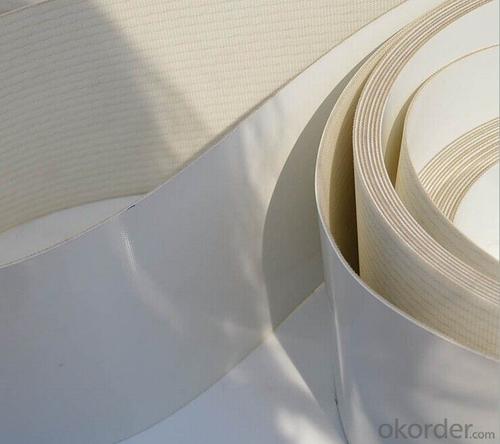

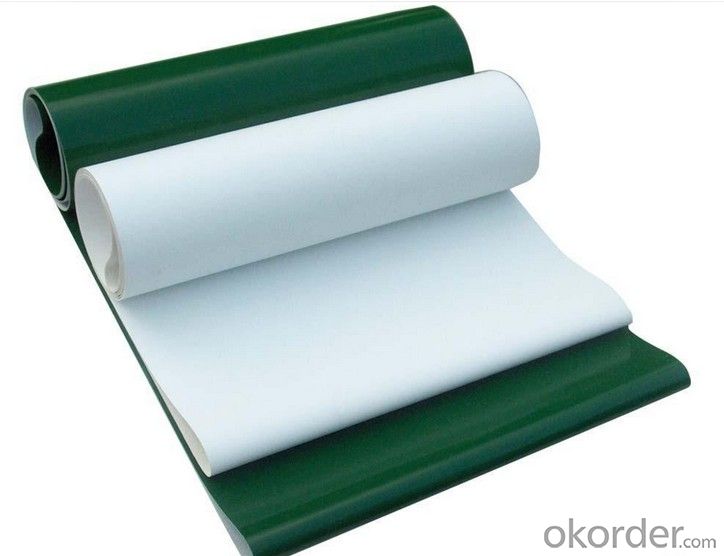

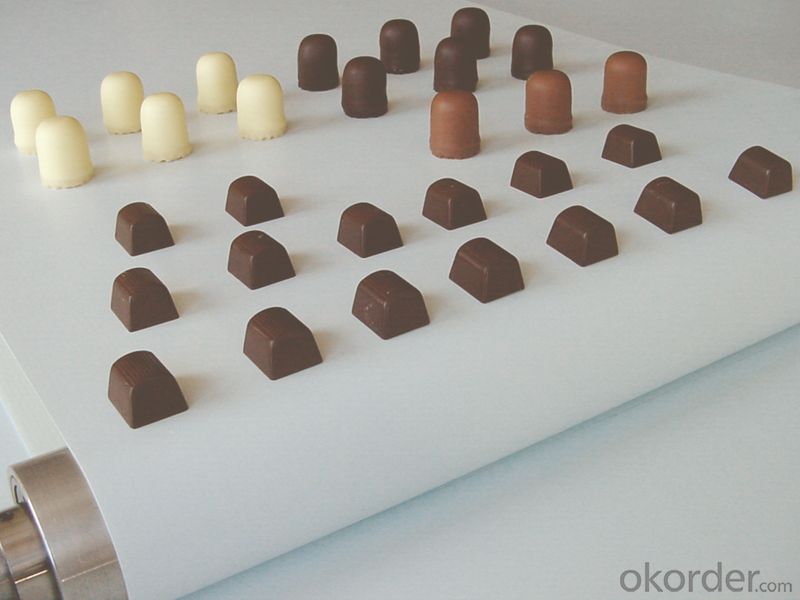

PVC conveyor belts are made of PVC which is commonly abbreviated PVC and polyester fabric, it's working temperate range is from -10 to 80 degrees, with good lateral stability, now it is widely use in airports, postal automation, parcel handling, treadmills, packagin and wrapping, confectionery industry, food processing industry, paper printing industry and so on..

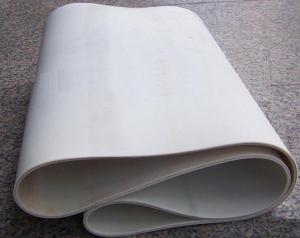

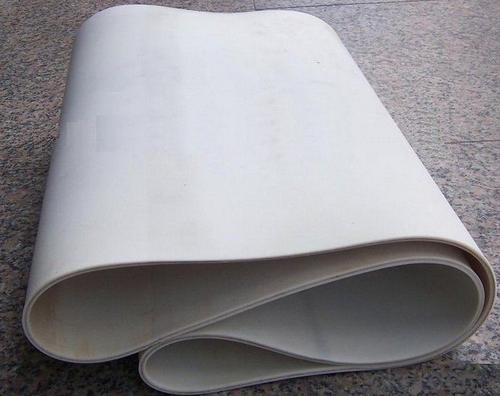

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What problems need to pay attention to when inflating the pipe?

- The charging pressure does not exceed the working pressure of the air sac, and the sharp object is prevented from scratching the gasbag during the inflating process

- Q: What's the difference between silicone rubber and 703.704 glue?

- 703, temperature range of -50-150, water resistance, salt water effect is good, mainly used for cable potting, instrument waterproof seal, watchcase bonding;

- Q: What are the rubber parts for the car?

- Filter rubber parts, cloth (diaphragm), injection pump sealing ring, car frame sealing strip, door seal..... There are many, the car inside the big, small, a lot of rubber products. Watch more and you'll see.

- Q: Can rubber products be injection molded and plastic injection functions?

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding. Die casting method. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Natural rubber (NR) with rubber hydrocarbon (polyisoprene), containing a small amount of protein, carbohydrate, moisture, acid resin and inorganic salts. Flexibility, high tensile strength, tear resistance and excellent electrical insulation, good wear resistance and drought tolerance, processing of good, easy to other materials than in adhesive the performance of most synthetic rubber. The disadvantage is resistance to oxygen and ozone resistance, easy aging deterioration; oil resistance and solvent resistance is not good, the anti acid corrosion resistance low; heat resistance is not high. The temperature range of about - 60 DEG C ~ + 80 DEG C. Production of tires, rubber shoes, rubber hose, rubber belt wire and cable insulation and sheath as well as other common products. Especially suitable for manufacturing the torsional vibration eliminator, engine shock absorber, machine bearings, rubber metal diaphragm, suspension components, molded products.

- Q: Is it necessary to use rubber products for steel structure buildings?

- There must be a rubber cushion for the gear of the crane beam, and there is also a rubber cushion between the crane track and the crane beam. Of course, not all deformation joints are rubber, depending on how to choose the design node.

- Q: What are the reasons for rubber cracking after shock absorption of rubber products?

- The rubber itself is poor in tearing and its products are overloaded.

- Q: How do you remove the rubber on your new slippers?

- There must be some rubber smell, because the bottom containing rubber and plastic bags are used as fine without air so the rubber flavor will be heavier, and you wear for a period of time will not fall, or to buy after put in place of ventilation blowing for one or two days no taste.

- Q: What are the bridge rubber air bags used for?

- In the use of rubber inflatable mandrel, first check the reinforcement cage wire joint and rolling head not towards the diameter direction bending, so as not to prick core mold, forming

- Q: Will rubber products fade?

- Rubber products will fade, is a rubber aging process, mainly due to external factors, temperature changes, the use of time, light, chemicals, external force and so on.

Send your message to us

PVC Conveyor Belt with Skirt Sidewall Raised Edge Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords