Hygienic Green PVC Conveyor Belts In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hygienic Green PVC Conveyor Belts In Food Industry

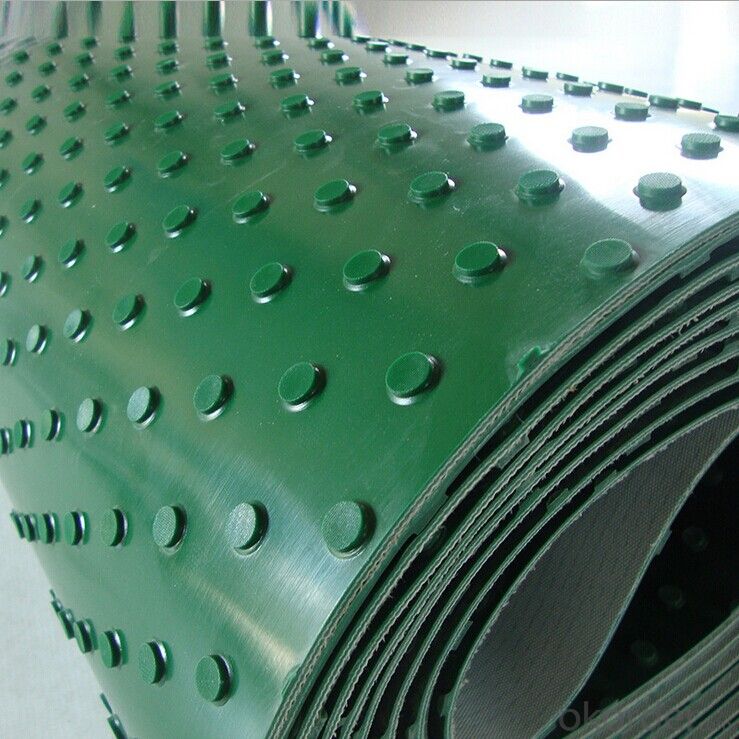

Descriptions of PVC Food Conveyor Belt

We are a highly reputed organization engaged in manufacturing and distribution of hygienic conveyor belts and food conveyor belts. Fabricated from FDA approved polymers, these food conveyor belts are available in high abrasion resistant, anti-static and oil resistant cover grades. Complying with ISO standards, these food belts are dimensionally accurate and available in standard as well as customized specifications.

These hygienic conveyor belts do not stain and odorize the materials to be conveyed and widely used in the food industries for appropriate handling of food stuffs. Our range of hygienic belts is stringently quality checked to ensure that they are free from any kind of defect.

Features of PVC Food Conveyor Belt

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Various surfaces with high, medium, and low coefficient friction

Dimensional stability

Less noise

Application areas of PVC Food Conveyor Belt

Most popular application include operations in the Sugar IndustryFood Products Organizations mainly use Hygienic Belts for their bulk handling packed materials.

Tea Estates are major users of Hygienic Belts for conveying of various varieties of Green Tea Leaves and forward conveying the same towards Drier Sections, and finally for the packed products.

Pharmaceutical Sectors are major user of Hygienic Belts in their manufacturing units for medicines and packing departments.

Sepcifications of PVC Food Conveyor Belt

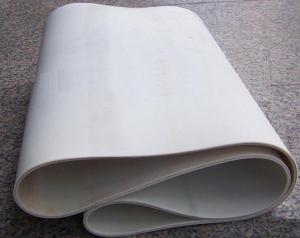

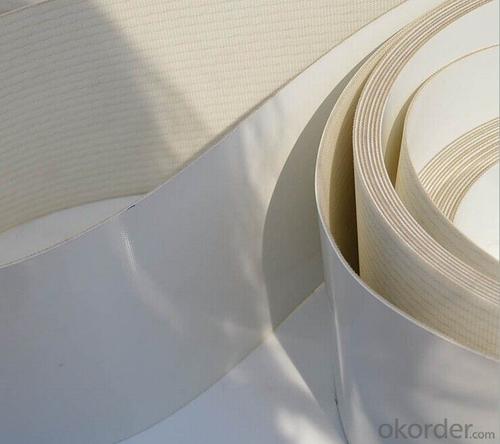

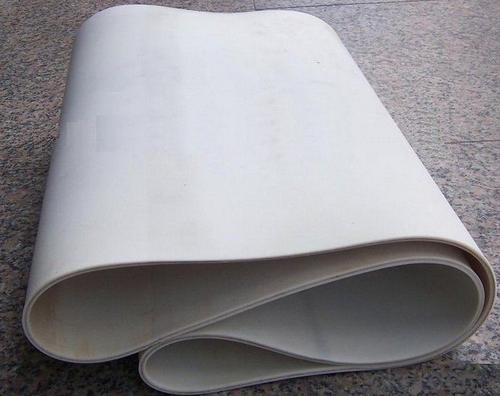

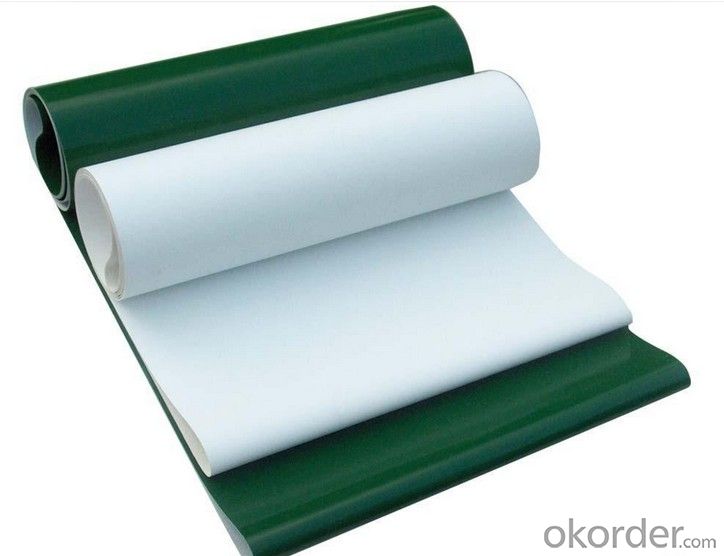

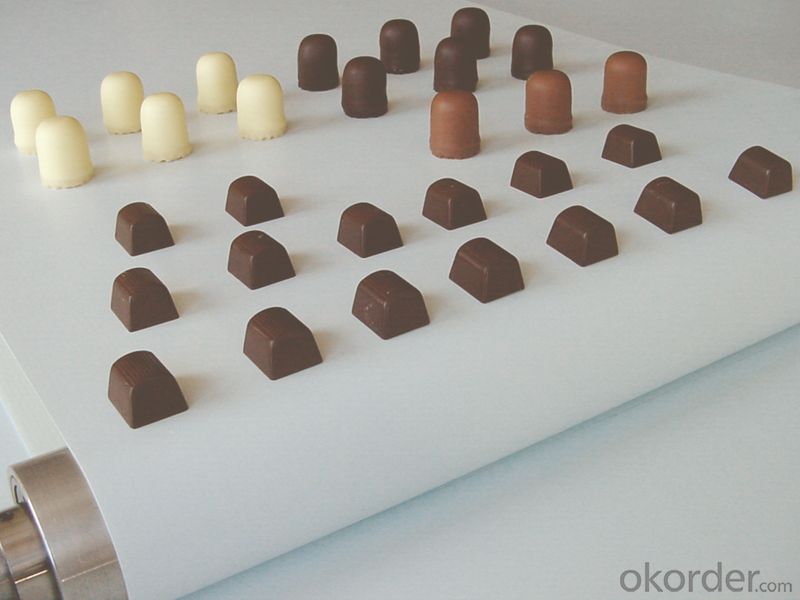

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the tensile strength of silicone rubber?

- The tensile strength range of silicone rubber is 3.4-14.7Mpa, depending on the formula!

- Q: What are the uses of ethylene propylene rubber?

- In the electrical and electronic industries, the main use of ethylene propylene rubber excellent electrical insulation, weather resistance and corrosion resistance, in many electrical components used in this kind of rubber. For example, the production of cables with ethylene propylene rubber, especially submarine cables, is replaced by EPDM or EPDM/PP instead of PVC/NBR. The insulation performance and service life of cables have been greatly improved. In the transformer insulation pad, electronic insulation sheath is also a large number of ethylene propylene rubber production.Ethylene propylene rubber combined with other rubber is also a great field of ethylene propylene rubber applications. EPDM can be used in conjunction with other rubbers to improve performance and reduce costs. But due to various complex agents on the affinity of different polymers, covulcanization depends on the polymer crosslinking efficiency of different polymers and may not reach the molecular level compatible blend, but there were no phase separation system. The unequal distribution of complexing agents has a major impact on the properties of ethylene propylene and rubber.

- Q: What are the common rubber products, please tell me

- Rubber is a high elastic polymer compound, which has high elasticity that other materials do not have, so it is also called elastomer. Its main feature is the enormous molecular weight

- Q: Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber chloroprene as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength rubber, heat resistance and light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good

- Q: What's rubber skin?

- Rubber is divided into natural rubber and synthetic rubber by raw materials. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories.

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- Hydrogenated nitrile rubber (HNBR) is a highly saturated elastomer obtained by the special hydrogenation of nitrile butadiene rubber. Hydrogenated nitrile rubber has good oil resistance (of fuel oil, lubricating oil, aromatic solvent resistance and good); and due to their high saturation, which has good heat resistance, excellent chemical resistance (of freon, acid and alkali resistance is good, excellent) ozone resistance, high anti compression permanent deformation performance; at the same time the hydrogenated nitrile rubber also has high strength, high tear resistance, excellent wear resistance and other characteristics, is one of the most outstanding performance of the rubber.

- Q: The action of various ingredients in rubber formula

- Performance system: reinforcing agent, colorant, foaming agent, fragrance agent, hardening agent, plasticizer, flame retardant, antistatic agent

- Q: What kind of material does the shockproof rubber cushion usually choose? What's the hardness?

- Of course is to choose butadiene rubberThe biggest characteristic is the molecular structure, mainly for the CIS structure, so the elasticity, cracking resistance and dynamic performance is excellent, and the rubber pad shock proof function is guaranteed, and the rubber cushion life is guaranteed, and the hardness is about 55.

- Q: What are the causes of the rubber products breach?

- Rubber aging is a common problem of rubber products, and aging is mainly due to internal structure or component is easy to aging due to weakness, such as unsaturated double bond, branched, carbonyl, hydroxyl and so on; at the end, the main external or environmental factors are sunlight, oxygen, ozone, heat, water and mechanical stress force, high energy radiation, electricity, industrial gas, water, salt fog, fungi, bacteria, insects etc..

- Q: What are the hazards of waste rubber and how can they be used for regeneration?

- The disposal of waste rubber is one of the serious problems facing people today. In order to meet the requirements of materials to improve the performance of rubber, towards high strength, wear resistance, stability and aging resistance of the direction of development, but also caused a long period of rubber not biodegradable waste after a large number of waste rubber, causing than plastic pollution (white pollution) more difficult to deal with the black pollution. On the other hand, precious rubber resources are wasted.

Send your message to us

Hygienic Green PVC Conveyor Belts In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords