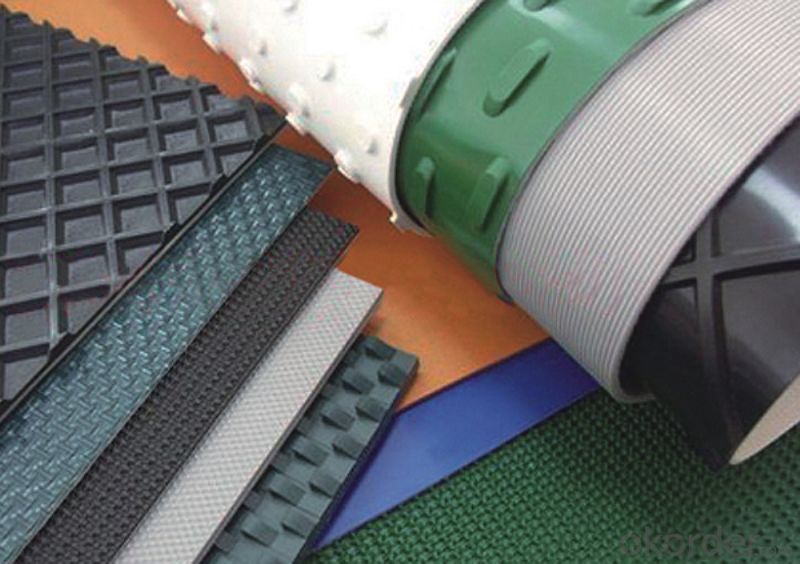

Green White Color PVC & PU Conveyor Belt for Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Processing Conveyor Belt

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Can olive nets be used for both short and long-term crop protection?

- Yes, olive nets can be used for both short and long-term crop protection. These nets are designed to protect olive trees and crops from various external factors such as birds, insects, and extreme weather conditions. They can be easily installed and removed, making them suitable for short-term protection during specific seasons or events. Additionally, olive nets are durable and can withstand prolonged use, making them effective for long-term crop protection throughout the year.

- Q: Can olive nets be used in combination with rootstock selection methods?

- Yes, olive nets can be used in combination with rootstock selection methods. Olive nets are primarily used to protect the olive trees and their fruits from pests, birds, and adverse weather conditions. Rootstock selection methods, on the other hand, involve choosing the appropriate rootstock for olive trees based on their resistance to diseases, growth characteristics, and environmental conditions. Both these techniques serve different purposes but can be used simultaneously to ensure optimal growth and protection of olive trees.

- Q: Can olive nets be customized for specific orchard layouts?

- Yes, olive nets can be customized to accommodate specific orchard layouts. Different sizes, shapes, and configurations can be tailored to fit the specific needs and dimensions of an orchard, ensuring optimal coverage and protection for the olive trees.

- Q: What are the hazards of plastic products to people?

- Plastic bags really bring convenience to our life, but this temporary convenience brings long-term harm

- Q: Can olive nets be used for olive trees in regions with limited labor availability?

- Yes, olive nets can be used for olive trees in regions with limited labor availability. Olive nets are designed to capture the olives as they naturally fall from the trees during harvest, minimizing the need for manual labor to collect them. This makes them particularly useful in regions where there is a scarcity of labor resources. Olive nets can efficiently and effectively collect the olives, allowing farmers to harvest their crop with minimal manpower.

- Q: Can olive nets be used in regions with strong winds?

- Olive nets can be used in regions with strong winds, but it is important to take certain precautions. It is recommended to use heavier and stronger materials for the nets to withstand the wind force. Additionally, securing the nets properly and regularly inspecting them for any damages or weaknesses is crucial to ensure their effectiveness.

- Q: Can olive nets be used in areas with extreme temperatures?

- Yes, olive nets can be used in areas with extreme temperatures. Olive nets are designed to protect olive trees from pests and wind, and they are typically made of durable materials that can withstand different weather conditions, including extreme temperatures. However, it is important to ensure that the nets are properly installed and maintained to prevent any potential damage.

- Q: How can plastics be produced? In several ways?

- Press molding is also known as molding or pressing, and molding is mainly used for molding thermosetting resins such as phenolic resin, urea formaldehyde resin and unsaturated polyester resin.

- Q: Can olive nets be used on trees with a small trunk?

- Yes, olive nets can be used on trees with a small trunk. Olive nets are designed to protect the olives from birds and other pests, regardless of the size of the tree trunk. They can be easily draped over small trees and secured to prevent any damage to the olives.

- Q: Do olive nets protect against olive tree diseases other than olive fruit flies?

- No, olive nets primarily protect against olive fruit flies and not other diseases affecting olive trees.

Send your message to us

Green White Color PVC & PU Conveyor Belt for Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords