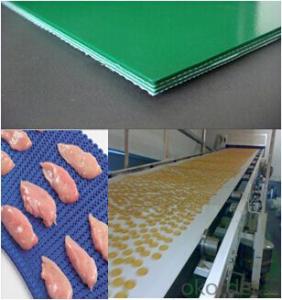

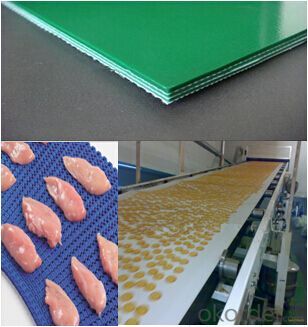

Green/White PVC/PU Conveyor Belt Used in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green/White PVC/PU Conveyor Belt Used in Food Industry

Product Description:

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Working temperature ranges from -10 to 80Deg.C

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

Product Pictures:

- Q: What are the applications of rubber airbags in the automotive field?

- Rubber accounts for 5% of the total weight of automotive materials, with an average of 100200 rubber parts per car, with a total number of 200500. Along with the automobile reliability, environmental protection and energy saving requirements continue to increase, and rubber materials, product structure optimization, improve the heat resistance, low temperature resistance, long aging, oil resistance, leakage resistance, long-term fatigue, and further reduce the cost has become the main topic of the development of automotive rubber. Fluorine rubber, silicone rubber, acrylic rubber and other special heat-resistant elastic body will still be the mainstream of the future direction of the development of automobile rubber.

- Q: Process for producing rubber products

- There are many kinds of rubber products, but the production process is basically the same. The basic process of rubber products in general solid rubber - rubber as raw materials including: plastication, mixing, calendering, extrusion, molding, curing 6 basic processes. Of course, raw materials preparation, finishing, inspection, packaging and other basic processes are indispensable. The processing of rubber mainly deals with the contradictory process of plasticity and elasticity. Through a variety of techniques, the elastic rubber plastic rubber has become the addition of various additives made of semi-finished products, and then through the vulcanization has semi-finished plastic and rubber products into high elasticity and good mechanical performance.

- Q: What is the pressure on rubber products during vulcanization?

- Usually, the selection of curing pressure need to consider several factors, namely rubber formulation, rubber plastic size, forming die structure (filling pressure, injection pressure, injection type), type of curing equipment (flat vulcanizing machine, vulcanizing machine, injection machine, injection of sulfur with sulfide vacuum machine etc.) and product structure features.

- Q: How can I make rubber products brighter?

- Special release agent for rubber products, release agent.Mold release agent is an interface coating used on two surfaces that are easy to adhere to each other. It can make the surface of the material easy to break off, smooth and clean. Mold release agent is used in various molding processes, such as glass fiber reinforced plastics, metal die casting, polyurethane foam and elastomer, injection molding thermoplastic, vacuum foaming sheet and extrusion section. In molding, sometimes other plastics, such as plasticizers, leak to the interface, and then a surface remover is needed to remove it.

- Q: What is the lowest cost material for the synthesis of rubber?

- There are many kinds of synthetic rubber. Many kinds of materials are used in synthesis, which material is lower or can not be measured

- Q: Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- The product has good elasticity and anti compression deformation, and has excellent aging resistance. It adopts the microwave vulcanization process to form at one time. The surface is smooth and beautiful, without any trace.

- Q: What is rubber leather?

- Special rubber refers to rubber with some special properties. The main contents are as follows: chloroprene rubber. CR, prepared by polymerization of chloroprene. With good overall performance, oil resistance, combustion resistance, oxidation resistance and ozone resistance. But its density is larger, it is easy to crystallize at room temperature, hard to store, cold resistance is poor. Nitrile rubber. Referred to as NBR, made by copolymerization of butadiene and acrylonitrile. Good oil resistance and aging resistance. It can be used in the air of 120 degrees Celsius or in the oil at 150 degrees centigrade for a long time. In addition, it also has water resistance, air tightness and excellent adhesive properties. Silicone rubber. The backbone consists of alternating atoms of silicon and oxygen, with organic groups on silicon atoms. High and low temperature, ozone resistance, good electrical insulation. Fluorine rubber. A synthetic rubber containing fluorine atoms in the molecular structure. Usually, the number of fluorine atoms in the fluorine containing unit in the copolymer is expressed as fluorine rubber 23, and the copolymer is two vinylidene fluoride and three fluorine vinyl chloride. Fluorine rubber, high temperature, oil resistance, chemical resistance. Polysulfide rubber. Condensation of two halides with sulfides of alkali or alkaline earth metals. Has excellent oil resistance and solvent resistance, but the strength is not high, aging resistance, poor processability, odor, and more with nbr. In addition, there are polyurethane rubber, epichlorohydrin rubber, acrylic rubber and so on.

- Q: What adhesive does rubber and wood have better glue?

- Rubber and wood bonded with ergo5500 rubber glue better.

- Q: What are the bridge rubber air bags used for?

- Open the valve, inflated to the specified pressure, you can close the valve, must not exceed the pressure.

- Q: What about rubber molding, foaming and layering?

- Return the glue (the rubber has not been used up after heat treatmentThe glue and the new rubber are mixed together to heat up, and the remaining glue is called a return glue. When the mixture is mixed with the new rubber, the mixture is uneven and the degree of vulcanization is not uniform, resulting in delamination

Send your message to us

Green/White PVC/PU Conveyor Belt Used in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords