Green/White/Blue PVC/PU Conveyor Belt in Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green/White/Blue PVC/PU Conveyor Belt in Light Industry

Description:

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

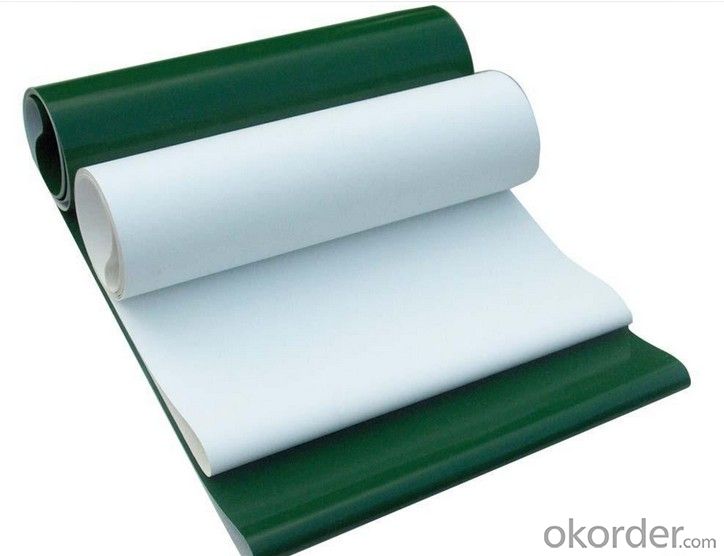

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

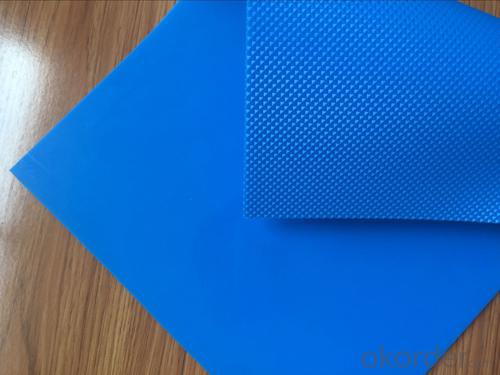

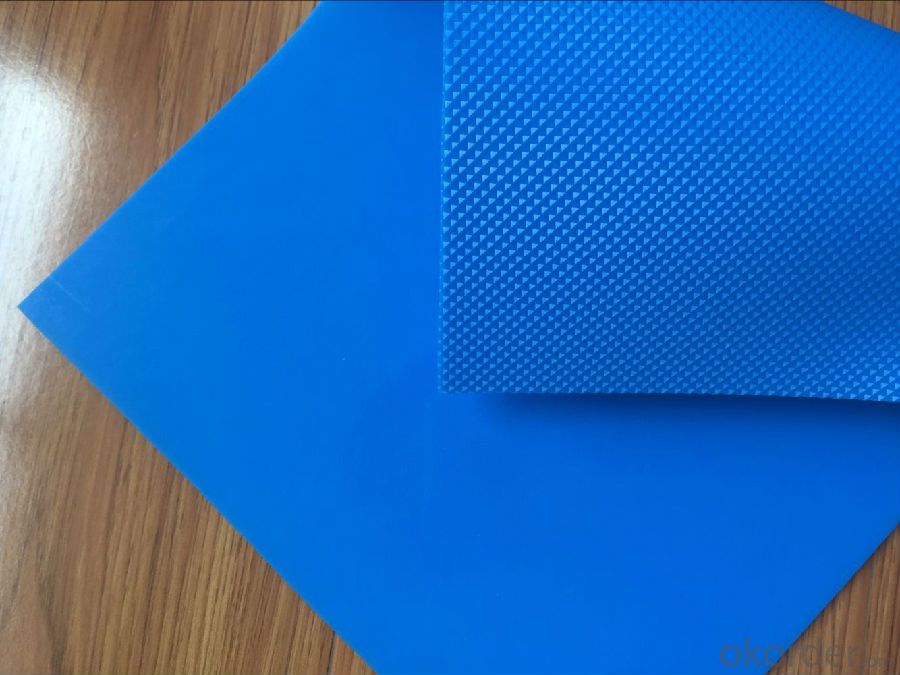

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Applications

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

Photos

- Q: Are there any specific guidelines for using olive nets on old or mature olive trees?

- Yes, there are specific guidelines for using olive nets on old or mature olive trees. It is recommended to choose nets that are large enough to cover the entire canopy of the tree, ensuring that no olives are exposed. The nets should be securely fastened to prevent wind damage or birds from accessing the olives. Additionally, it is important to regularly check the nets for any tears or gaps that may compromise their effectiveness. Harvesting should be done carefully to avoid damaging the branches or the tree.

- Q: How does an olive net affect the overall erosion control in the olive grove?

- An olive net can significantly improve erosion control in an olive grove. By covering the ground beneath the trees, the net prevents soil erosion caused by heavy rainfall or strong winds. It also helps retain moisture in the soil, reducing water runoff and promoting healthy root growth. Additionally, the net acts as a barrier, preventing soil compaction and protecting the topsoil from being washed away. Therefore, the overall effect of an olive net is to enhance erosion control and maintain the stability and productivity of the olive grove.

- Q: How do olive nets help in reducing the risk of fruit drop?

- Olive nets help in reducing the risk of fruit drop by providing a physical barrier that prevents the olives from falling to the ground. These nets are placed under the olive trees to catch the ripe fruits as they naturally detach from the branches. By catching the olives, the nets prevent them from hitting the ground and potentially getting damaged or infected by pests or diseases. This protective measure helps to ensure a higher yield and better quality olives for harvesting.

- Q: Are there any specific guidelines for using olive nets on young or newly planted olive trees?

- Yes, there are specific guidelines for using olive nets on young or newly planted olive trees. It is recommended to only use lightweight nets that allow sunlight, air, and rain to pass through. The nets should be securely attached to prevent any damage to the trees or branches. Additionally, it is important to regularly check the nets for any entanglement or damage, as well as adjust them as the trees grow.

- Q: How do you protect olive nets from rodents or other pests?

- One way to protect olive nets from rodents or other pests is by installing wire mesh or netting around the perimeter of the olive trees. This physical barrier prevents pests from accessing the nets and damaging the olives. Additionally, using organic pest control methods, such as introducing predator insects or utilizing natural repellents, can help deter rodents and other pests from approaching the olive nets.

- Q: Can olive nets be used in olive groves with limited access to labor?

- Yes, olive nets can be used in olive groves with limited access to labor. Olive nets are commonly used in olive groves to facilitate the harvesting process by catching the olives as they fall from the trees. This method reduces the need for manual labor during harvesting, making it feasible for groves with limited access to labor. The nets can be placed strategically under the trees, allowing the olives to drop onto them and be collected easily. Using olive nets in such groves can help maximize efficiency and minimize dependency on labor-intensive harvesting methods.

- Q: Can olive nets be used in olive groves with limited access to sunlight?

- Yes, olive nets can be used in olive groves with limited access to sunlight. Olive nets are primarily used to protect the olives from birds and other pests, and they do not rely on sunlight for their functionality. However, it is important to ensure that the olive trees still receive sufficient sunlight for their growth and productivity even with the presence of the nets.

- Q: How do olive nets affect the labor required for olive harvesting?

- Olive nets can significantly reduce the labor required for olive harvesting. These nets are spread under the olive trees, allowing the olives to fall onto them when they are shaken or picked from the branches. The nets then collect the fallen olives, making it much easier and faster to collect a large quantity of olives. This eliminates the need for manual picking and reduces the labor-intensive process of bending down to collect individual olives from the ground. Overall, olive nets streamline the harvesting process, making it more efficient and reducing the labor involved.

- Q: Can olive nets be used in combination with mulching techniques?

- Yes, olive nets can be used in combination with mulching techniques. Mulching helps to retain soil moisture and suppress weeds, while olive nets are used to catch falling olives during harvest. By using both methods together, farmers can effectively control weed growth and protect the olives from damage, ensuring a successful harvest.

- Q: Are olive nets easy to set up and take down?

- Yes, olive nets are generally easy to set up and take down. They are designed to be lightweight and user-friendly, allowing users to easily install and remove them from olive trees or plants.

Send your message to us

Green/White/Blue PVC/PU Conveyor Belt in Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords